Square tube splicing device

An assembly device and square tube technology, applied in auxiliary devices, transportation and packaging, conveyors, etc., can solve the problem of accuracy, pre-assembly state maintenance, positioning accuracy affecting the quality of finished products, high automation requirements, and unstable assembly In order to achieve the effect of saving manpower, reducing the difficulty of operation and meeting the needs of automatic production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

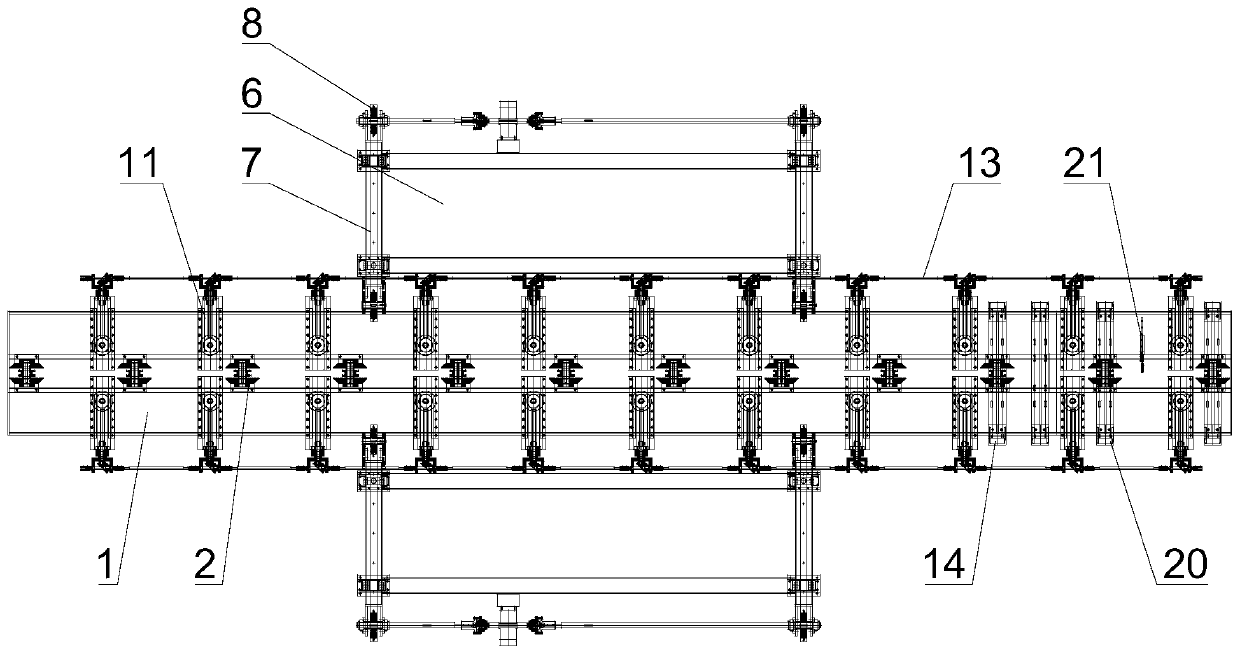

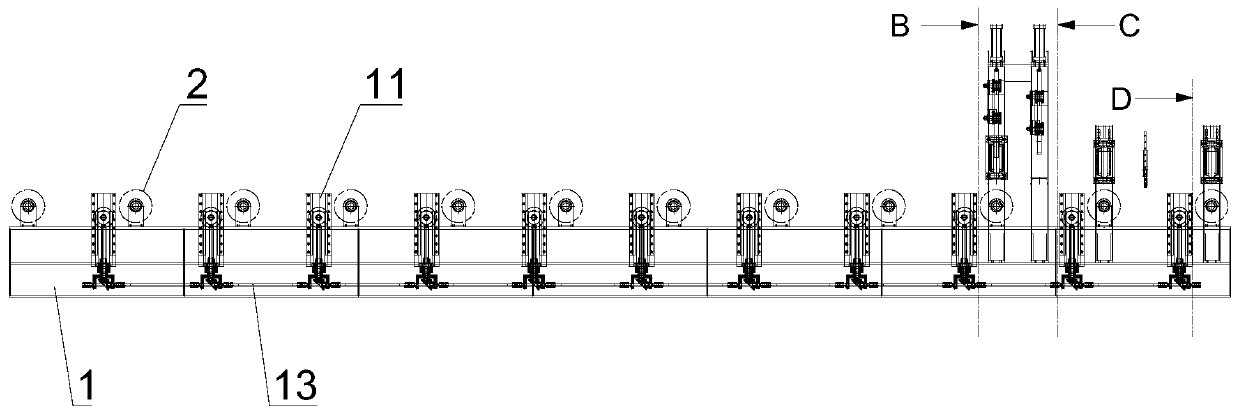

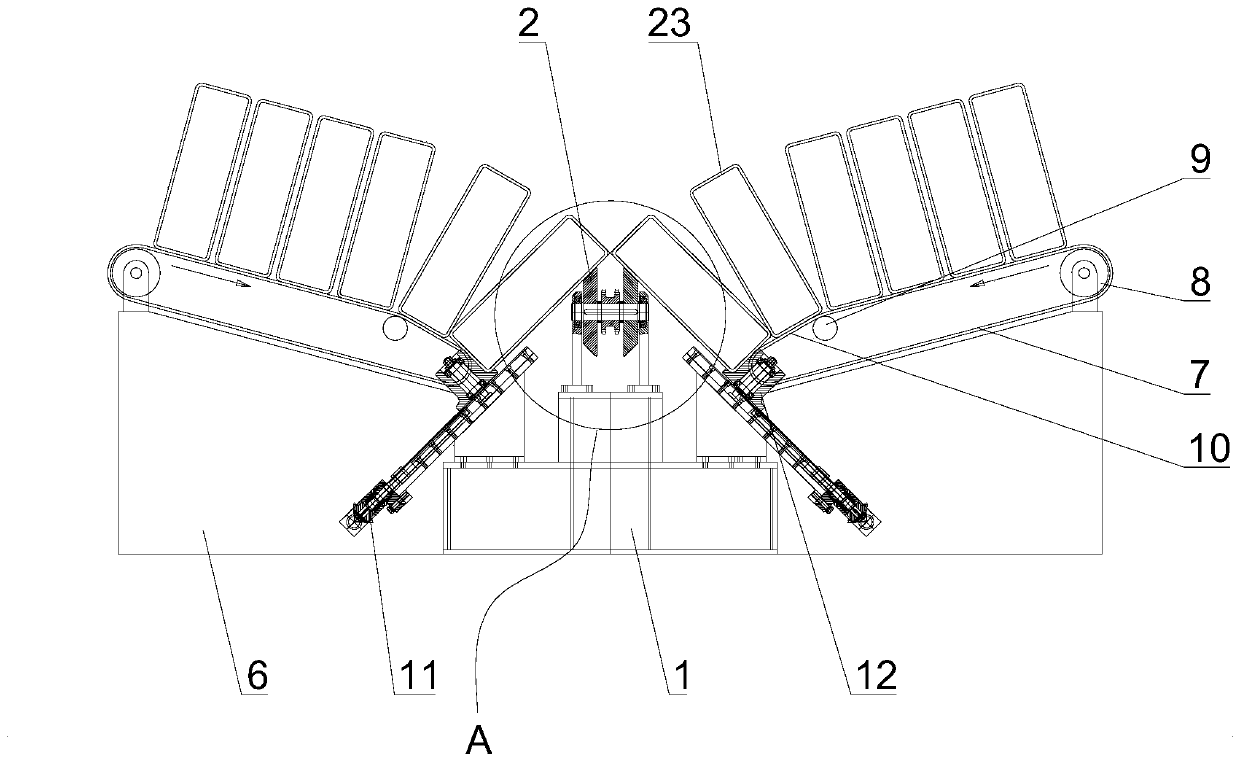

[0030] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

[0031] see Figures 1 to 7 As shown, this embodiment provides a square tube assembling device, which is used for splicing two square tubes in an "L" shape. Of course, it can also be an oblique assembling form at other angles, and only needs to adjust the arrangement angle of each component adaptively.

[0032] The device includes a support seat 1, a feeding mechanism, a pre-assembly mechanism, a limit mechanism and a welding mechanism.

[0033] The support base 1 is provided with conveying rollers, and several conveying rollers are arranged at intervals along the length direction of the support base 1 to form a production conveying line. The conveying roller includes two tapered surface wheels 2 inclined on both sides, a drive shaft 3, a drive wheel 4 and a mounting frame 5. The drive wheel 4 and the two tapered wheels 2 are r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com