Cutting head device and shaver

A cutter head and integrated technology, applied in the field of cutter head device and razor, cutter head device, can solve the problems of increasing the noise of the cutter head, unfavorable production and assembly, and increasing the noise of the shaver, so as to reduce the temperature rise and vibration intensity , Improve the comfort of use, improve the effect of shaving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

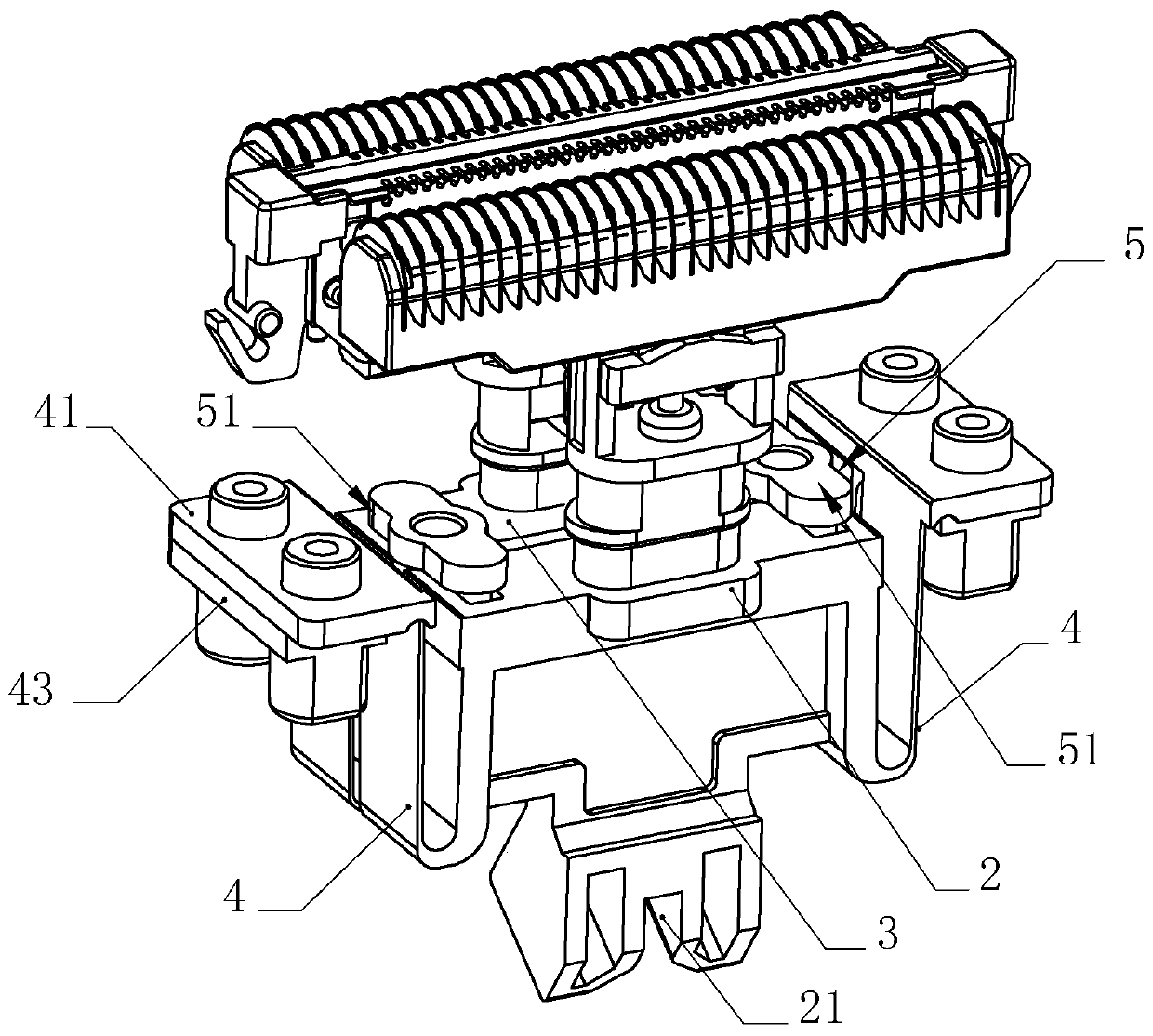

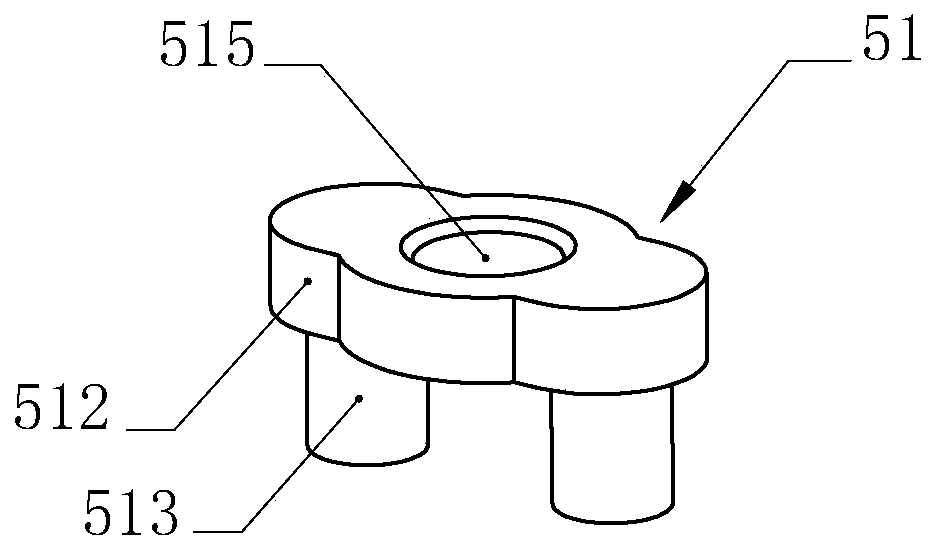

[0039] Such as Figure 2-9 As shown, in order to facilitate the horizontal reciprocating swing of the first swing frame 2 under the drive of the driving parts, the second swing frame 3 can be synchronized with the first swing frame 2 to swing in the opposite direction, and the movement of the two swing frames in opposite directions To buffer the kinetic energy inertia caused by the swing, reduce the vibration amplitude of the cutter head, and reduce the vibration intensity of the cutter head. The transmission member 5 includes two first linkages 51, two first linkages 51 are arranged, and are installed on the two ends of the first swing frame 2 and the second swing frame 3 respectively, when the first swing frame 2 When the driving part is driven to reciprocate horizontally, the second pendulum frame 3 can also move synchronously and reversely under the drive of the two first linkages 51, and in the process of reverse swinging, it is affected by the two first linkages. The li...

Embodiment 2

[0042] Such as Figure 10-16 As shown, the inventor has also proposed a transmission structure different from that of Embodiment 1. This transmission structure can not only ensure the reverse reciprocating motion of the double cutter head, but also ensure the first pendulum frame 2 and the second pendulum at the same time. To swing the frame 3 at intervals in parallel, the technical solution adopted is: the transmission member 5 includes a second linkage member 52, a third linkage member 53 and a fourth linkage member, and the third linkage member 53 and the fourth linkage member are the same Both are composed of two guide shafts 531 and guide grooves 532 matched with the guide shafts 531; the guide grooves 532 are respectively arranged at both ends of the first swing frame 2 and the second swing frame 3, and the direction of the guide grooves 532 is the same as that of the first swing frame. The swing directions of the frame 2 and the second swing frame 3 are consistent, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com