A device for collecting copper foil ear material of a raw foil machine

A collection device, raw foil machine technology, applied in thin material handling, transportation and packaging, metal processing and other directions, can solve problems such as reducing collection efficiency, prone to tearing, problems, etc., to ensure tightness, prevent tearing, The effect of improving collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

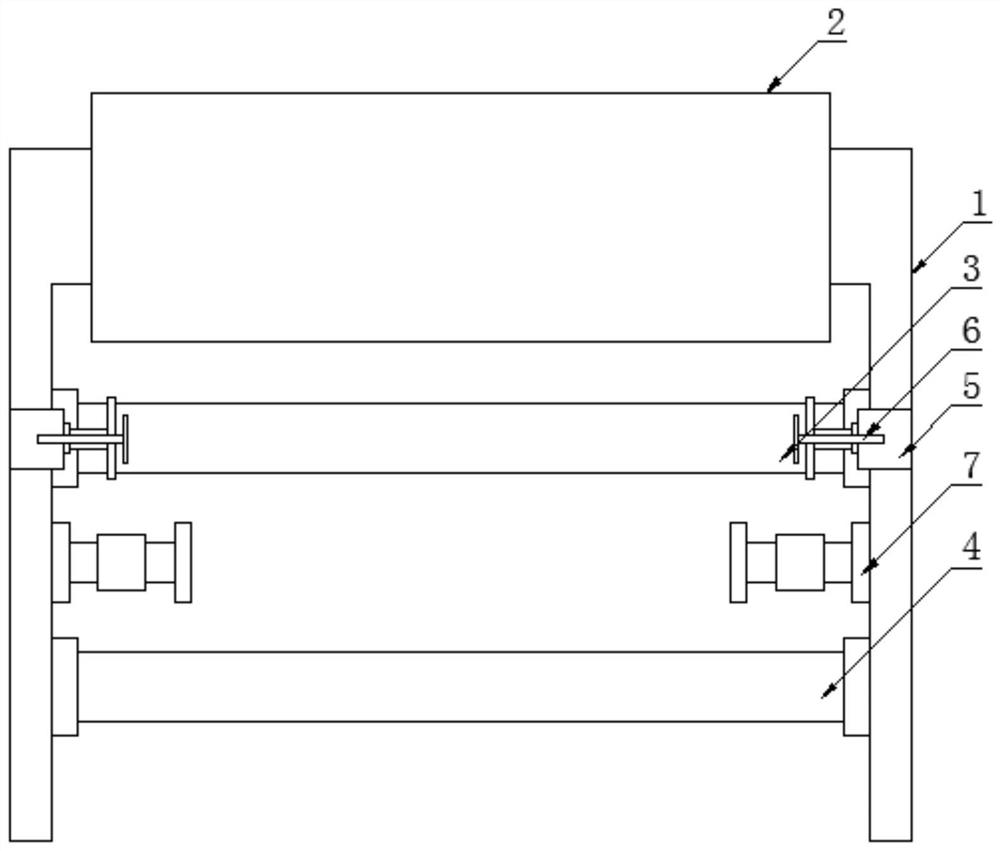

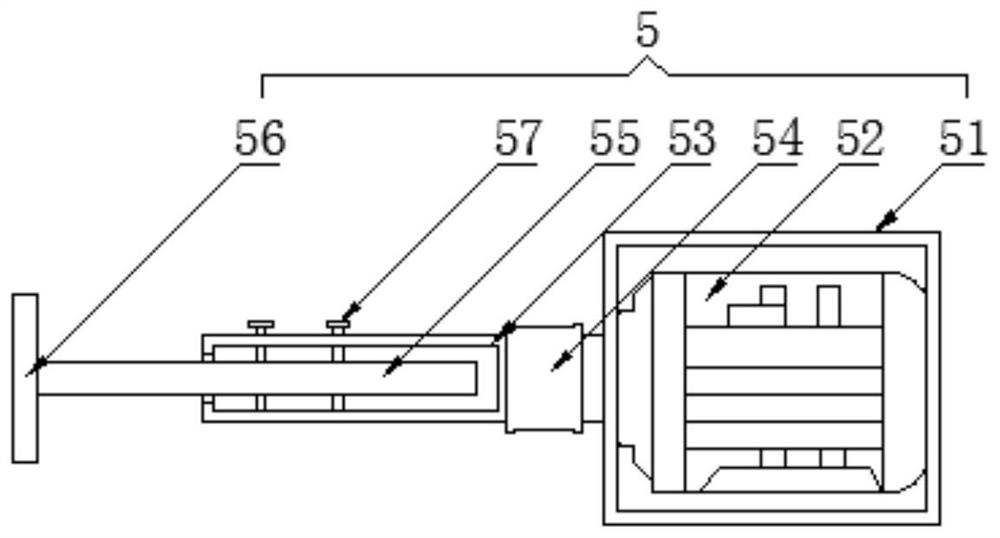

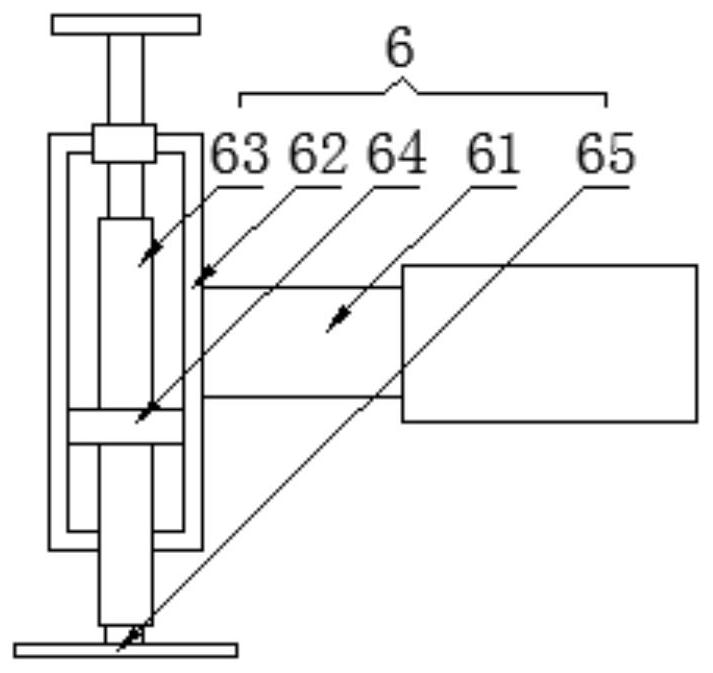

[0033] Example: The copper foil metal raw material in the container 2 is electrolyzed through the internal anode and cathode, so that the copper foil metal raw material is electrolyzed into copper foil, and the electrolyzed copper foil passes through the first transmission shaft 3 and the second transmission shaft The shaft 4 is used for conveying, and the first transmission shaft 3 and the second transmission shaft 4 rotate at the same speed through the driving mechanism, so as to ensure that the thickness of the copper foil after processing is the same. The control switch is connected to the power supply to run the driving motor 52, and the driving motor 52 runs to drive the rotating shaft 53 to rotate. Before cutting, the length of the cutting knife 56 on the rotating shaft 53 can be adjusted according to the width of the required cut, and the movable rod 55 can move in the rotating shaft 53 Adjust the position, then fix it by the limit rod 57, then when the rotating shaft 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com