Automatic ceramic thermal spraying device

A thermal spraying and ceramic technology, applied in coating, melting spraying, metal material coating process, etc., can solve the problems of no cooling function and low workpiece processing efficiency, and achieve a sufficient scope of action, improved processing efficiency, and convenient The effect of disassembling the workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

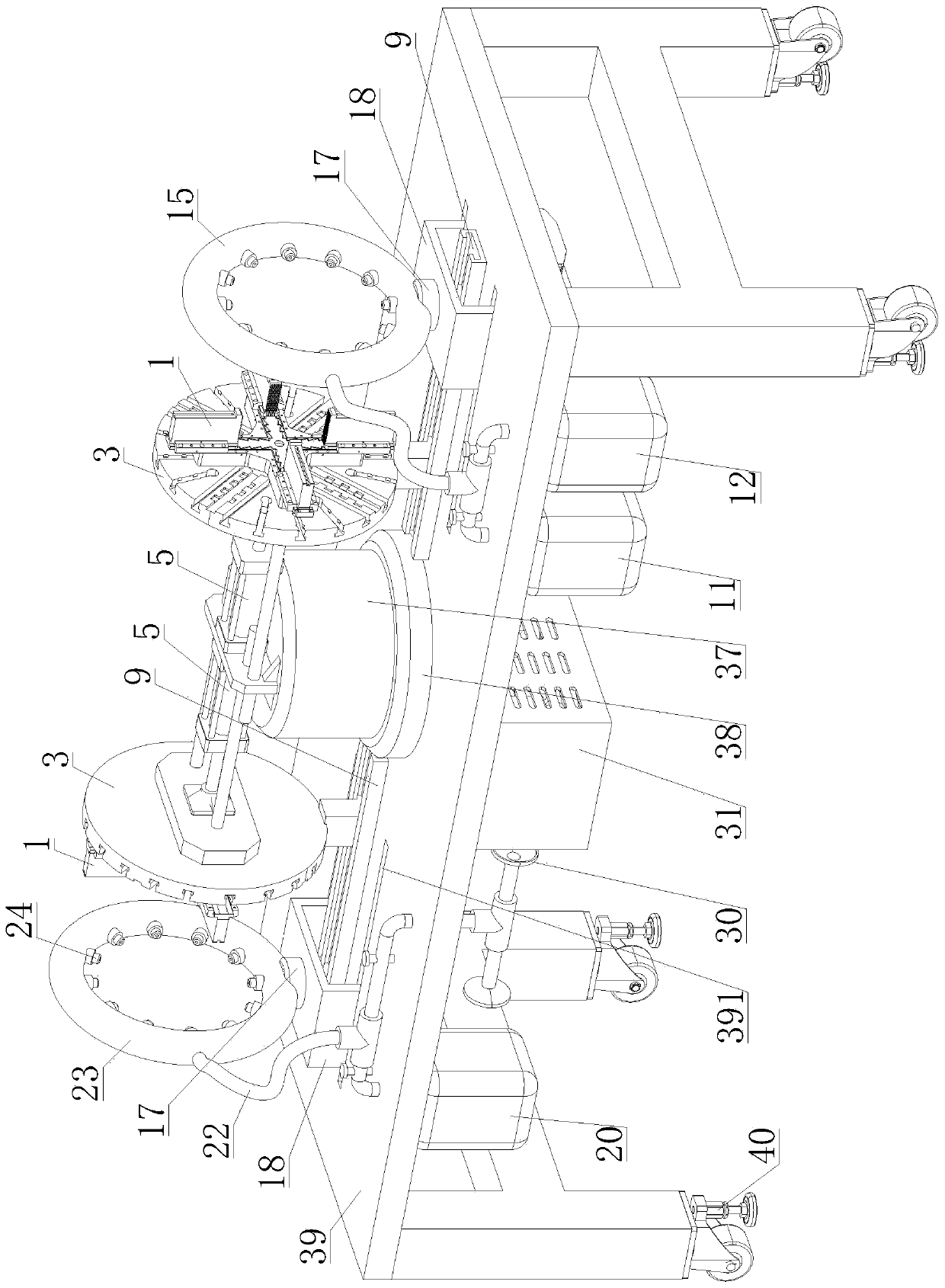

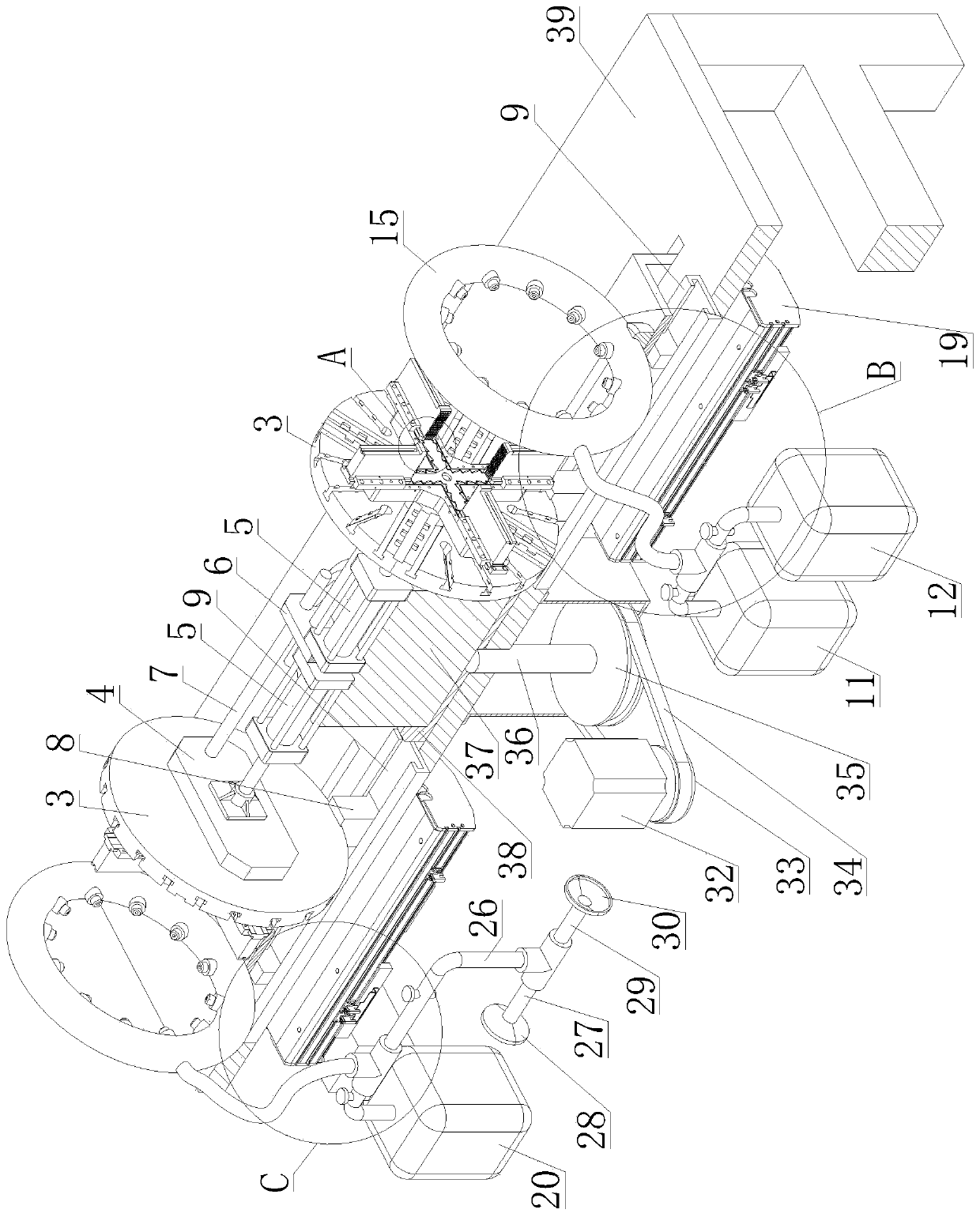

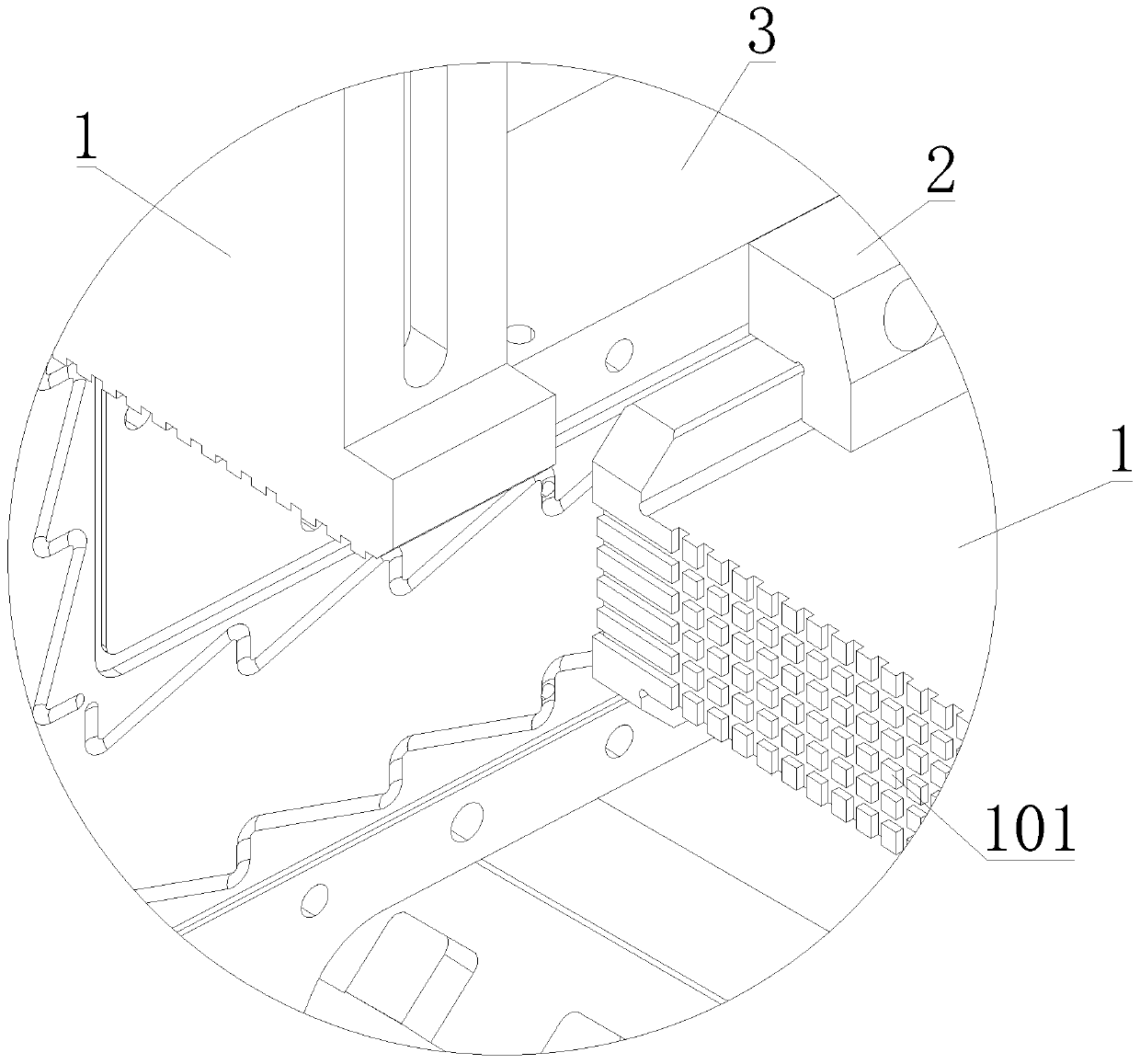

[0023] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

[0024] Such as Figure 1 to Figure 5 As shown, a kind of automatic ceramic thermal spraying equipment described in the present invention includes a clamping mechanism, a raw material tank 11, a first connecting pipe 111, an oxygen tank 12, a second connecting pipe 121, a first three-way pipe 13, a third Connecting pipe 14, first annular pipe 15, spray gun 16, second annular pipe 23, spray nozzle 24, mobile drive mechanism, blowing mechanism, turntable 37 and frame 39;

[0025] The raw material tank 11 and the oxygen tank 12 are all arranged on the frame 39, the raw material tank 11 communicates with the first three-way pipe 13 through the first connecting pipe 111, and the oxygen tank 12 communicates with the first three-way pipe 13 through the second connecting pipe 121 The two ends of the third connecting pipe 14 communicate with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com