Structure for installing special-shaped reinforcement cage in steel column of conversion layer and construction method of structure

A construction method and steel cage technology, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of easy deformation of steel cages, difficult hoisting, large diameter of steel bars in steel cages, etc., and achieve low construction difficulty, high construction quality, and smooth construction. The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

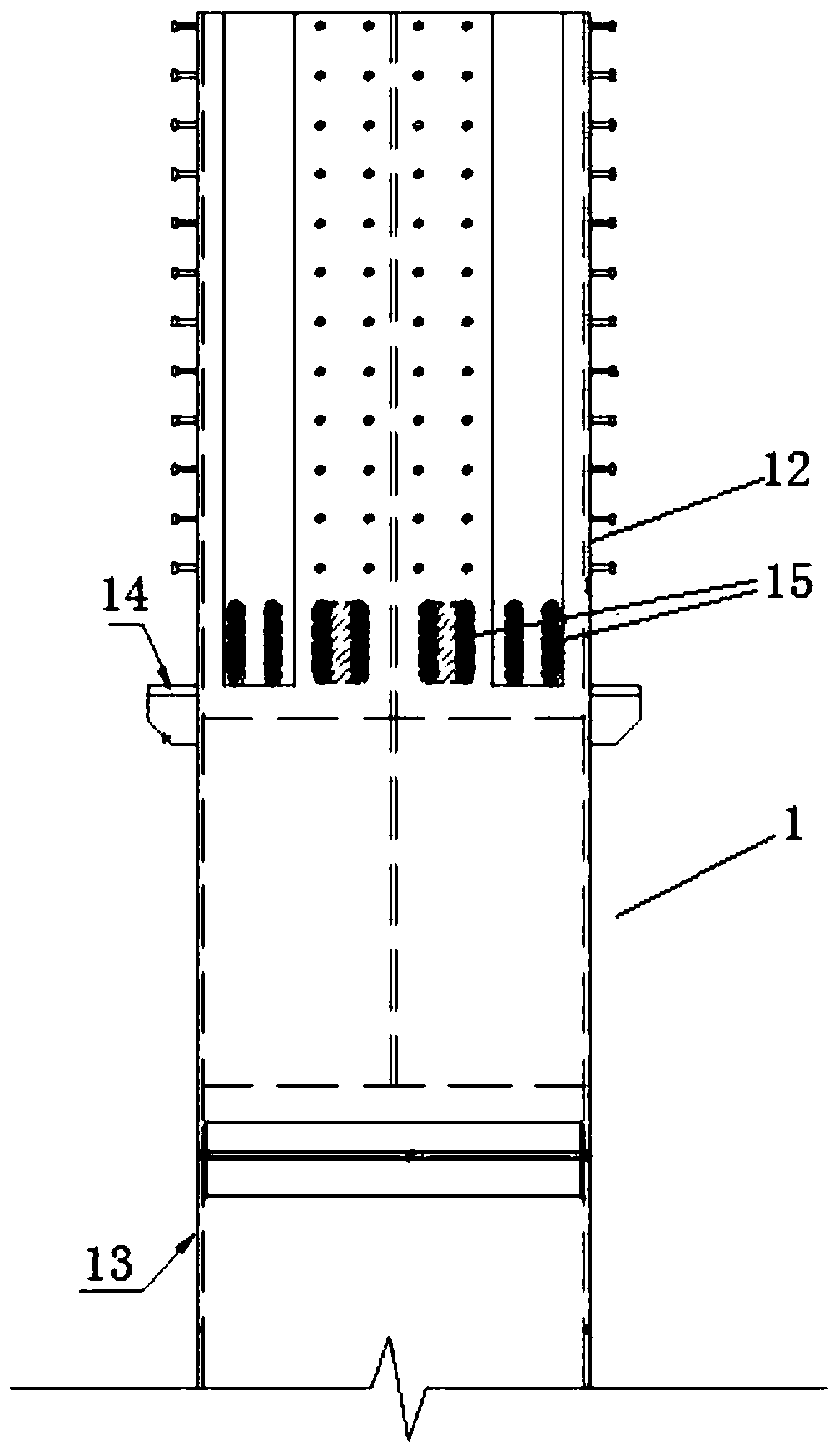

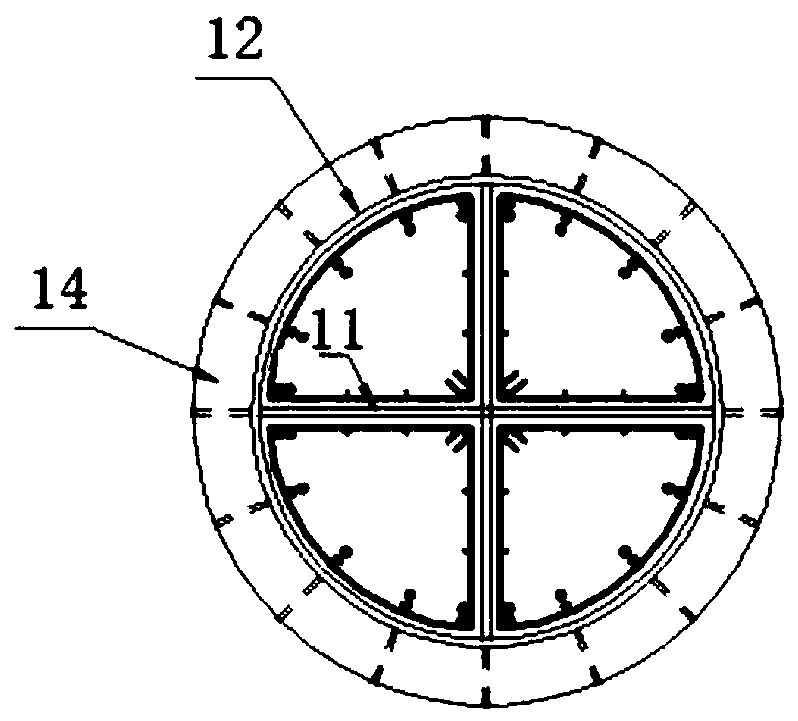

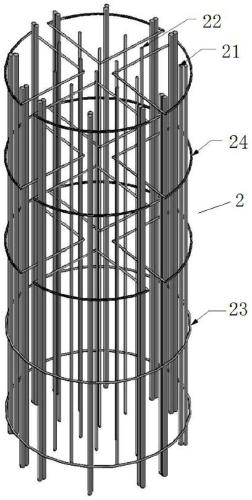

[0018] refer to Figure 1 to Figure 3 , the present invention provides a special-shaped reinforcement cage structure installed in the steel column of the conversion layer, including a circular steel pipe column 1 and a special-shaped steel cage 2, the special-shaped steel cage 2 is arranged in the circular steel column 1, and the special-shaped steel cage 2 includes an outer longitudinal The ribs 21 and the inner longitudinal ribs 22, the outer longitudinal ribs 21 are arranged along the circumferential distribution of the circular steel pipe column 1, the inner longitudinal ribs 22 are arranged along the cross-shaped web 11 inside the circular steel pipe column 1, and the outer longitudinal ribs 21 and The inner longitudinal bars 22 all extend to the next floor of the transfer layer, the bottom of the special-shaped steel cage 2 is provided with annular stirrups 23 for reinforcement, and the top of the special-shaped steel cage 2 is provided with fan-shaped stirrups 24 for rei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com