Sensor life test system and working method

A life test and sensor technology, applied to instruments, measuring devices, measuring fluid pressure, etc., can solve problems such as long cycle time and poor verification accuracy, and achieve the effect of ensuring detection accuracy and improving the test range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

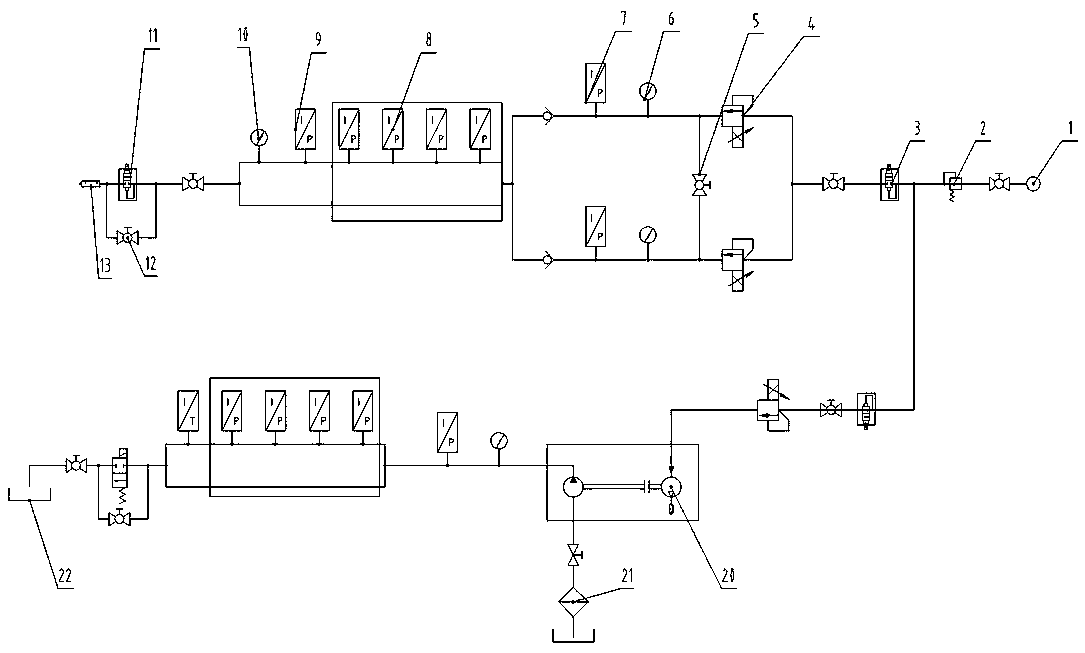

[0030] Embodiment 1: as figure 1 As shown, a sensor life test system includes an air source 1, and the air source 1 is connected to the air processing pipe network, and the air processing pipe network is respectively connected to the low-pressure test pipe network and the high-pressure test pipe network, which can test the sensor in the The test is carried out under different pressure conditions of low pressure or high pressure, which greatly improves the test range; the first pressure control pipeline and the second pressure control pipeline are respectively arranged in the low pressure test pipe network and the high pressure test pipe network, and the low pressure test pipe network and the The high-pressure test pipe network is equipped with sensor test pipelines and pressure relief pipelines, and the end of the low-pressure test pipe network is provided with a silencer. The silencer 13 can ensure that the noise of the test bench is at the lowest level when the pressure relie...

Embodiment 2

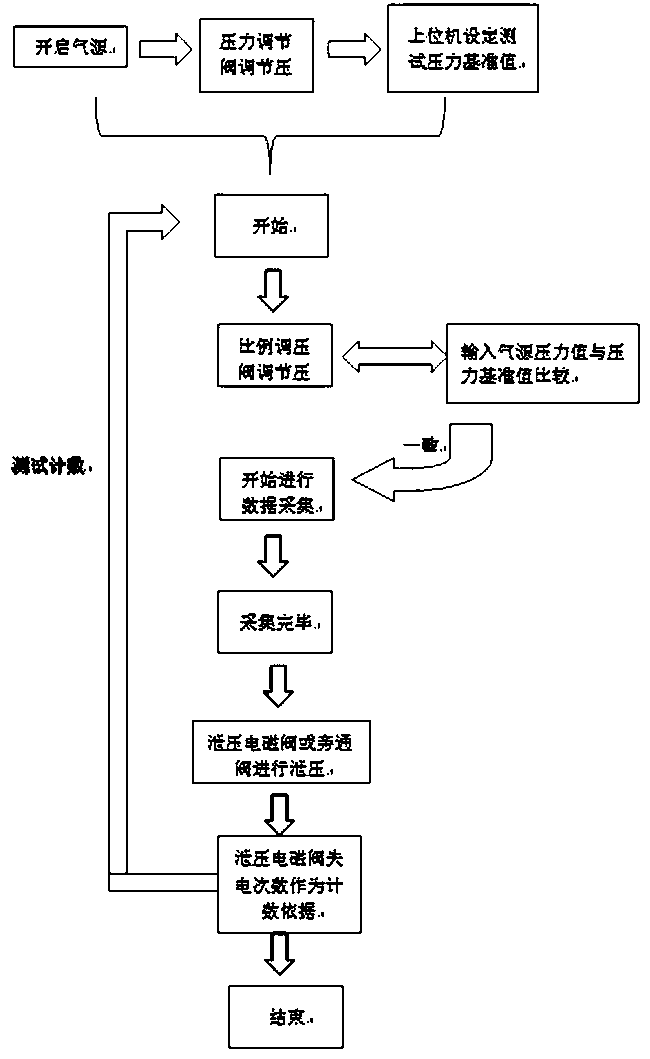

[0038] Example 2: as figure 2 As shown, a working method of a sensor life test system comprises the following steps:

[0039] S1. First turn on the air source 1, and the host computer controls the pressure regulating valve in the air processing pipeline to adjust the pressure of the input air source so that the output pressure of the air source is within a safe range, and then set the test pressure standard value through the host computer;

[0040] S2. The input air source enters the pressure control pipeline, and the upper computer controls the proportional pressure regulating valve in the pressure control pipeline to adjust the pressure of the input air source according to the set test pressure standard value, and the pressure detection in the pressure control pipeline The sensor detects the input air source pressure value in real time, and the upper computer receives the input air source pressure value detected by the pressure detection sensor in real time, and the upper c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com