Distributed optical fiber monitoring pre-buried groove

A technology of distributed optical fiber and pre-buried grooves, which is applied in the direction of optical fiber/cable installation, fiber mechanical structure, etc., can solve the problems of not fixing and limiting the light, so as to improve work performance, facilitate limiting and fixing, and ensure The effect of normal transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

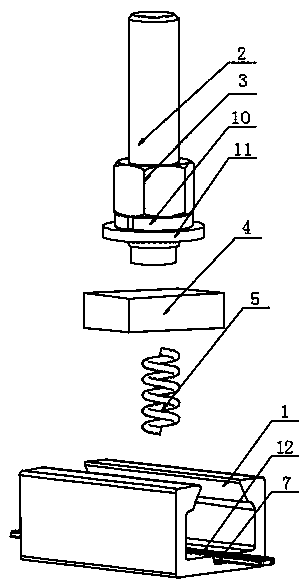

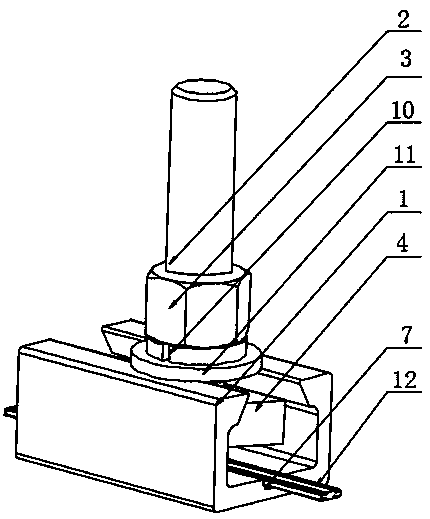

[0025] Refer to the attached Figure 1-2 , a distributed optical fiber monitoring cast-in groove according to this embodiment, comprising a cast-in groove body 1, a fixing mechanism is provided inside the cast-in groove body 1, and the fixing mechanism extends out of the top of the cast-in groove body 1;

[0026] The fixing mechanism includes a bolt 2, the bolt 2 is arranged on the top of the embedded groove body 1, the nut 3 is arranged outside the bolt 2, the nut 3 and the bolt 2 are connected by threads, and the bottom of the bolt 2 is provided with a limit Assemblies, the limiting assembly includes a fixed block 4, the top of the fixed block 4 is fixedly connected with the bottom of the bolt 2, the fixed block 4 is arranged inside the embedded groove body 1, and the bottom of the fixed block 4 is provided with a first spring 5. A T-shaped groove 7 is opened on the embedded groove body 1, and the T-shaped groove 7 is arranged at the bottom of the fixing block 4.

[0027] F...

Embodiment 2

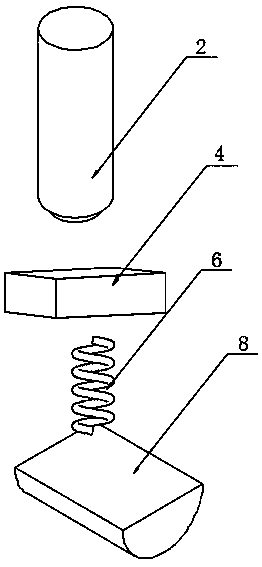

[0033] The difference with embodiment 1 is:

[0034] Refer to the attached Figure 3-4 , a distributed optical fiber monitoring embedded groove in this embodiment, the limit assembly includes a semi-cylindrical block 8, the top of the semi-cylindrical block 8 is fixedly connected to the bottom of the bolt 2, and the semi-cylindrical block 8 is arranged on the embedded Inside the tank body 1, the bottom of the semi-cylindrical block 8 is fixed with a second spring 6, and the embedded tank body 1 is provided with a semi-cylindrical groove 9, and the semi-cylindrical groove 9 is arranged at the bottom of the second spring 6 .

[0035] The specific implementation scenario is: when using the present invention, when there are few optical fibers 12 to be pre-embedded, if the optical fibers 12 are placed inside the T-shaped groove 7, since the space inside the T-shaped groove 7 is relatively larger, resulting in When the optical fiber 12 is pre-embedded, it is difficult to play a ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com