Multi-path high-precision high-voltage power supply

A high-voltage power supply and negative high-voltage power supply technology, applied in the field of electron sources, can solve the problem of no high-voltage power supply, and achieve the effects of convenient heat treatment and stable focusing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

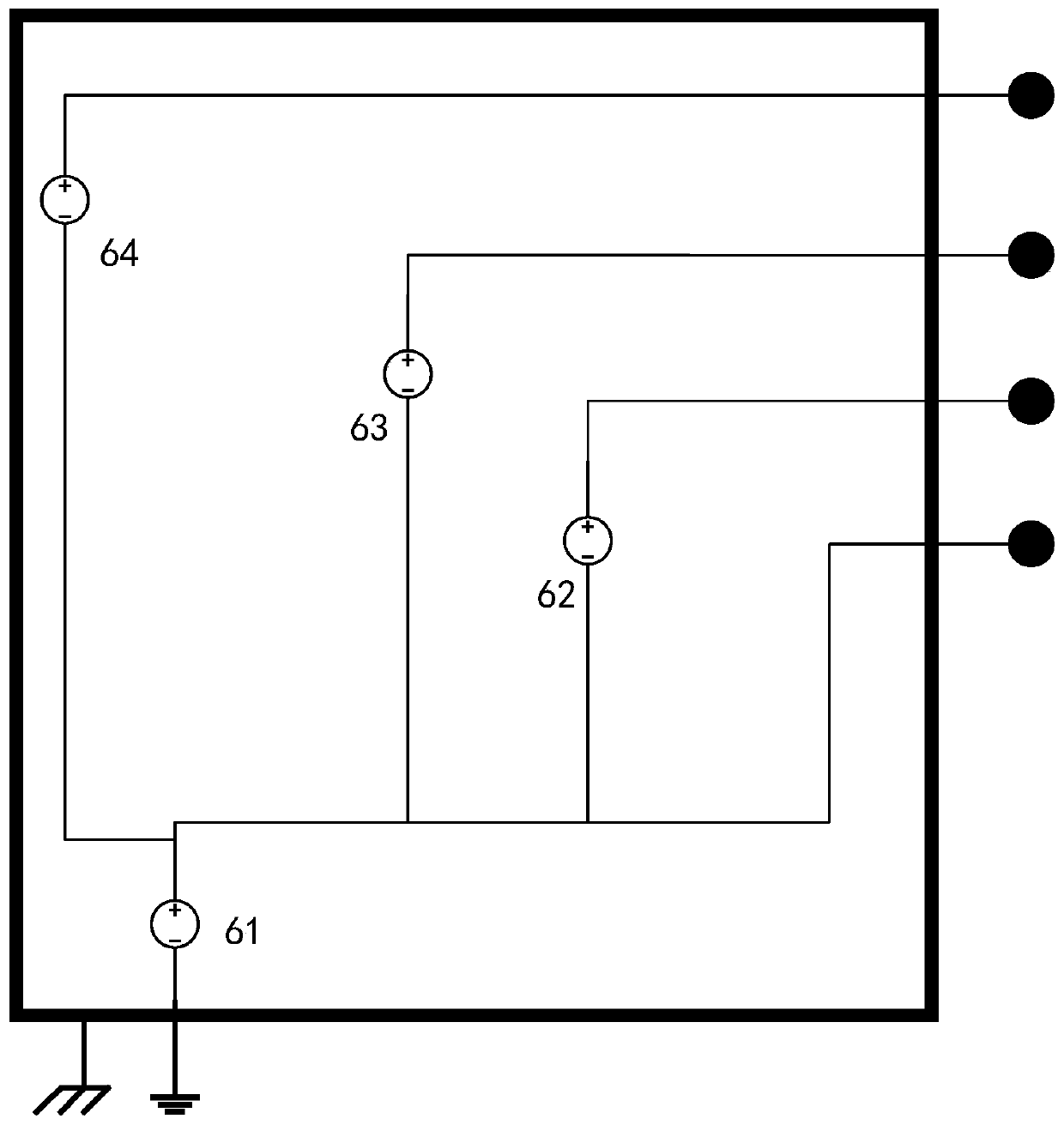

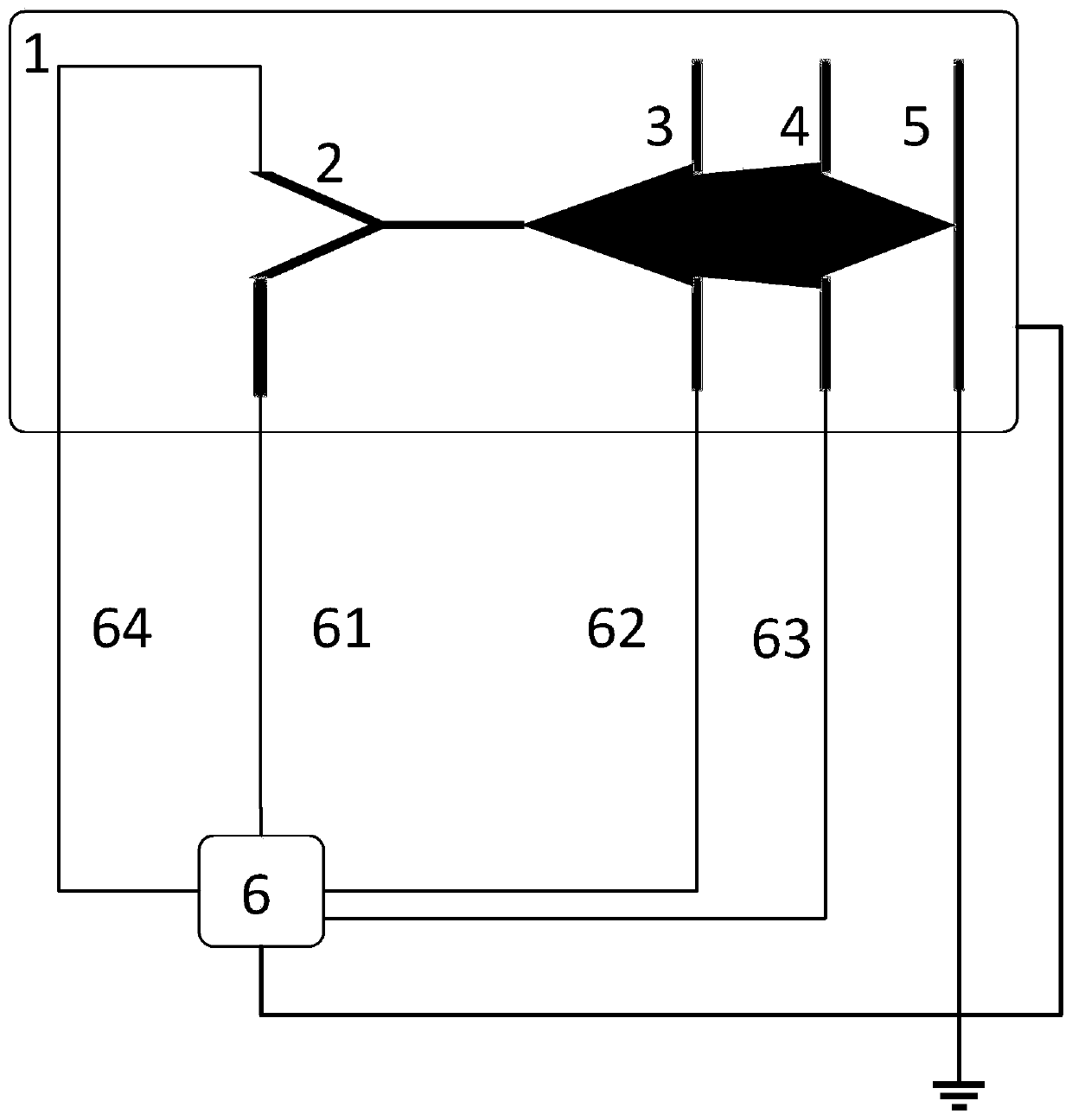

[0026] Such as figure 1 , figure 2 As shown, this embodiment provides a technical solution: a multi-channel high-precision high-voltage power supply, including:

[0027] The high-precision high-voltage power supply 6 includes a first high-voltage power supply 61, a second high-voltage power supply 62, a third high-voltage power supply 63, and a low-voltage power supply 64. Among them, the second high-voltage power supply 62, the second high-voltage power supply 62, and the low-voltage power supply The power sources 64 are all suspended above the first sub-high voltage power source 61.

[0028] Such as figure 1 As shown, the second sub-high-voltage power supply 62 and the second sub-high-voltage power supply 62 are directly suspended above the first sub-high-voltage power supply 61, and the output voltage and current can be monitored for all three.

[0029] The low-voltage power supply 64 is suspended above the first sub-high-voltage power supply 61 connected to the protection resist...

Embodiment 2

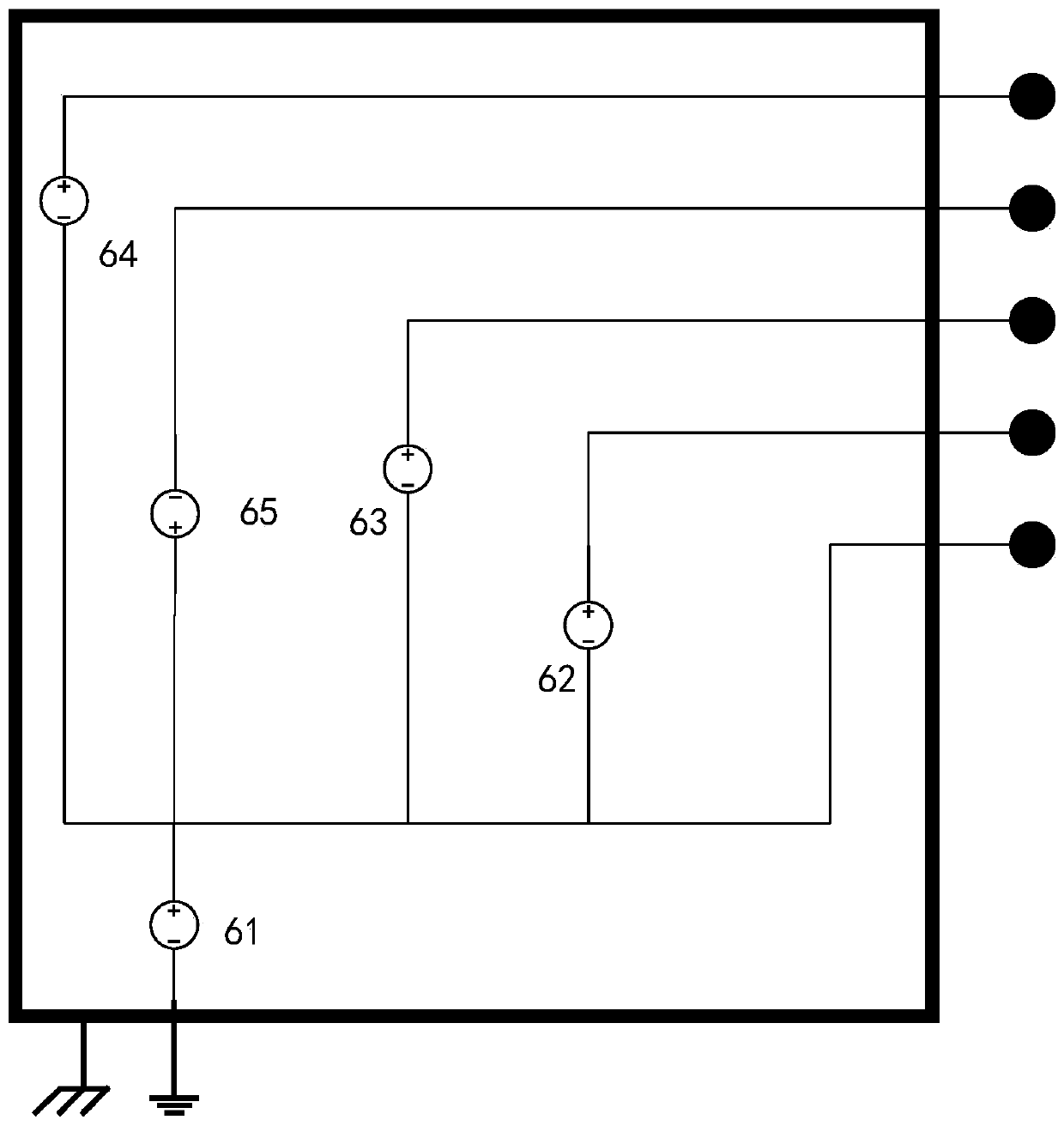

[0035] Such as image 3 , Figure 4 As shown, the high-precision high-voltage power supply includes at least 4 branch power supplies, except for the first sub-high-voltage power supply 61, the second sub-high-voltage power supply 62, the third sub-high-voltage power supply 63, and the low-voltage power supply 64 in the first embodiment. It may also include a fourth sub-high-voltage power supply, such as a negative high-voltage power supply 65, suspended on the first sub-high-voltage power supply 61 as the power supply for the compression pole 7 to adjust the electron beam emission angle.

[0036] The high-precision high-voltage power supply 6 is connected to the controlled micro-focus X-ray source 1 through a dedicated high-voltage cable and a high-voltage plug, and the micro-focus X-ray source 1 is placed in a vacuum chamber, such as Figure 4 Shown. The first divided high-voltage power supply 61 and the low-voltage power supply 64 are connected to both ends of the filament 2, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap