Low-temperature evaporative crystallization apparatus

A crystallization device and low-temperature evaporation technology, applied in the direction of evaporation separation crystallization, crystallization separation, chemical instruments and methods, etc., can solve the problems of inconvenient operation, high operating pressure, complex structure, etc., and achieve convenient operation, low operating pressure and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

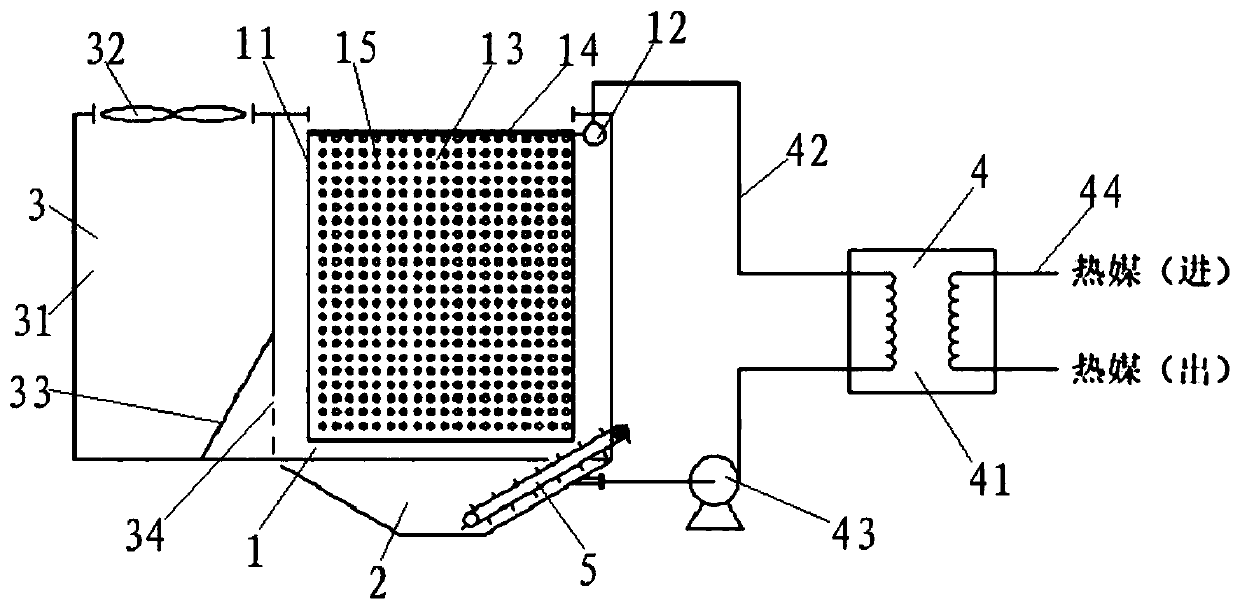

[0019] refer to figure 1 Shown, the low temperature evaporation crystallization device of the present invention, it comprises:

[0020] The curtain evaporator 1 includes an evaporation chamber 11, a plurality of evaporation modules and a jelly-distributing pipe 12, the top of the evaporation chamber 11 has an opening, and a plurality of evaporation modules are arranged inside the evaporation chamber 11, and each evaporation module includes a plurality of equidistant parallel The set cord assembly, each cord assembly includes a hydrophilic cord 13 and a water distribution branch pipe 14, the top of the hydrophilic cord 13 is hung on the water dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com