A high-efficiency and energy-saving steel slag powder preparation method

A high-efficiency, energy-saving, steel slag powder technology, applied in the field of comprehensive utilization of waste resources, can solve the problems of low powder selection efficiency, uneven particle size of steel slag powder, and increased energy consumption, so as to improve grinding efficiency, improve grinding efficiency, and improve fine grinding. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

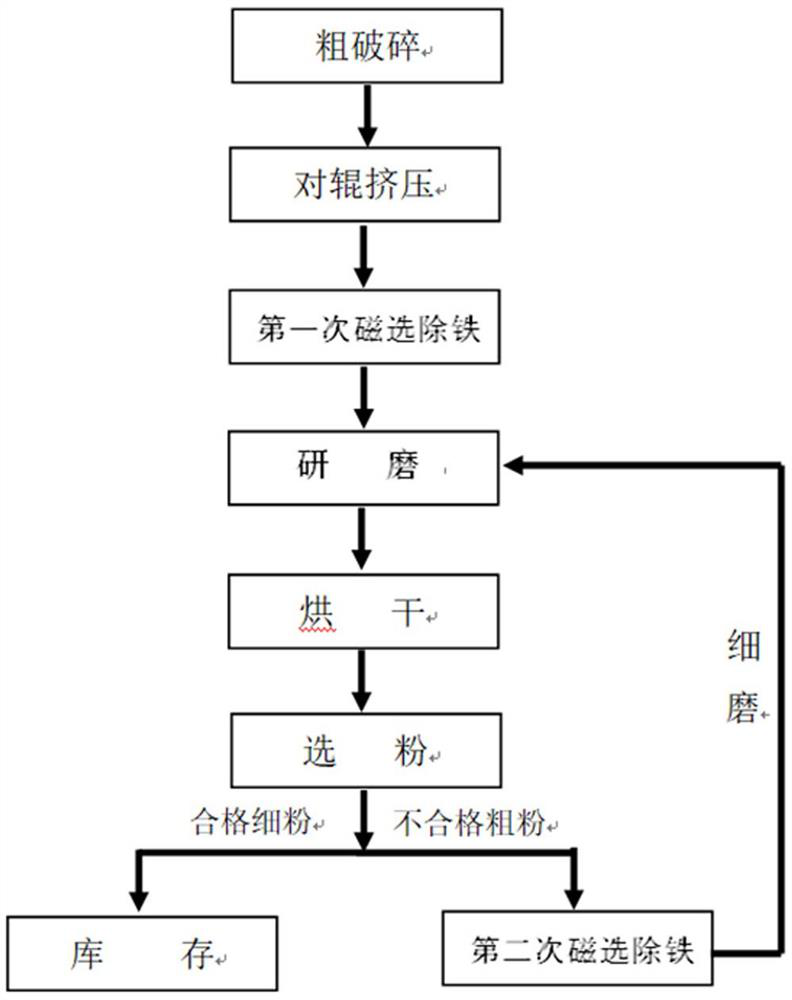

[0027] The present invention will be further described below in conjunction with accompanying drawing. Such as figure 1 Shown: a kind of highly efficient and energy-saving steel slag powder preparation method of the present invention, it comprises the following steps:

[0028] (1) Coarse crushing: The purchased large pieces of steel slag are crushed into 10-50mm steel slag particles by the jaw crusher. The crushed steel slag particles are screened by a bar type rotary screen to remove mechanical inclusions, and the large pieces of steel slag are returned for crushing. The qualified steel slag is transported by the belt conveyor to the double-roll extrusion machine for double-roll extrusion.

[0029] (2) Counter-roller extrusion: The qualified steel slag after rough crushing is transported to the feed port of the counter-roller extrusion machine by the belt conveyor, and the qualified steel slag is piled up in the feeding hopper to a certain height, and the steel slag at the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap