Dust removal device of tundish overturning area and dust removal method thereof

A technology of dust removal device and tundish, which is applied in the direction of removing smoke and dust, separation method, cleaning method and utensils, etc., to reduce pollution, improve work efficiency, and enhance sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

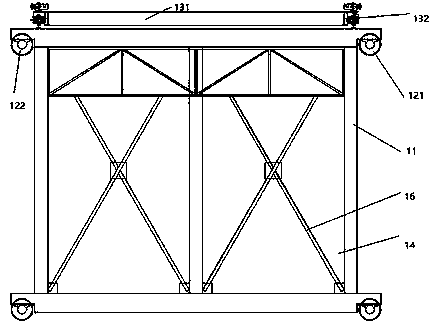

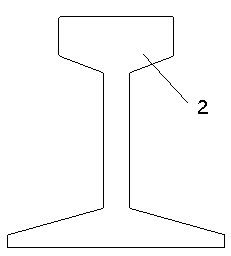

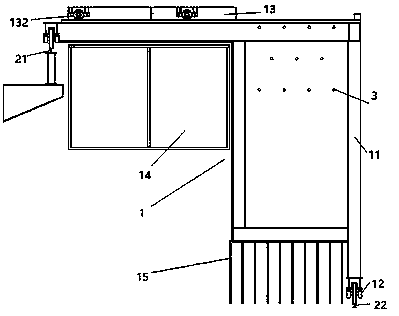

[0026] Such as figure 1 , figure 2 , Image 6 with Figure 7 As shown, a dust removal device for a tundish turning area includes a dust removal vehicle 1, a sliding track 2 and a spray system 3. The dust removal vehicle 1 is arranged on the sliding track 2 and located above the turning area. The sliding rail 2 includes an upper rail 21 and a ground rail 22. The upper rail 21 and the ground rail 22 are respectively arranged on both sides of the turning area. The upper rail 21 is laid on the beam extending from the factory column and above the turning area. The spray system 3 includes a spray pipe 31 and a nozzle 32. The spray pipe 31 is parallel to the sliding track 2 and passes through the top of the dust removal vehicle 1. The nozzles 32 are equally spaced in the spray pipe 31 on. There are 11 spray pipes 31 in total, 4 in the top layer, 3 in the middle layer, and 4 in the bottom layer. Each spray pipe 31 has a diameter of about 60 mm and is fixed on the dust removal vehicl...

Embodiment 2

[0031] Such as image 3 , Figure 4 , Figure 5 , Image 6 with Figure 7 As shown, a dust removal device for a tundish turning area includes a dust removal vehicle 1, a sliding track 2 and a spray system 3. The dust removal vehicle 1 is arranged on the sliding track 2 and located above the turning area. The sliding rail 2 includes an upper rail 21 and a ground rail 22. The upper rail 21 and the ground rail 22 are respectively arranged on both sides of the turning area. The upper rail 21 is laid on the beam extending from the factory column and above the turning area. The spray system 3 includes a spray pipe 31 and a nozzle 32. The spray pipe 31 is parallel to the sliding track 2 and passes through the top of the dust removal vehicle 1. The nozzles 32 are equally spaced in the spray pipe 31 on. There are 11 spray pipes 31 in total, 4 in the top layer, 3 in the middle layer and 4 in the bottom layer. The interlayer spacing is 800 mm, the interlayer spacing is 1000 mm, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com