Hole boring machine for tower crane lug plates

A technology of boring machine and lug plate, which is applied in the field of tower crane lug plate boring machine, can solve the problems of complex structure, inability to carry high-altitude operations, and large volume, so as to improve applicability, facilitate assembly and portability, and reduce volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following are specific embodiments of the present invention, and further describe the technical solution of the present invention in conjunction with the accompanying drawings, but the present invention is not limited to these embodiments.

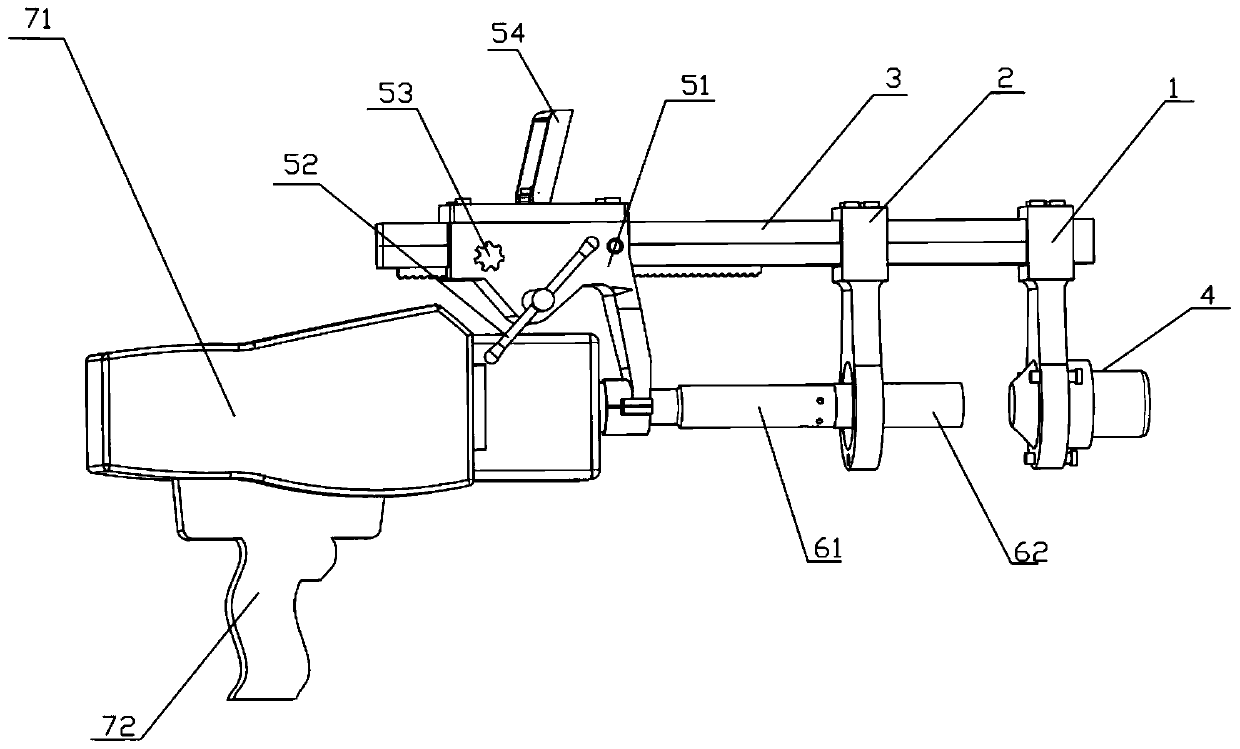

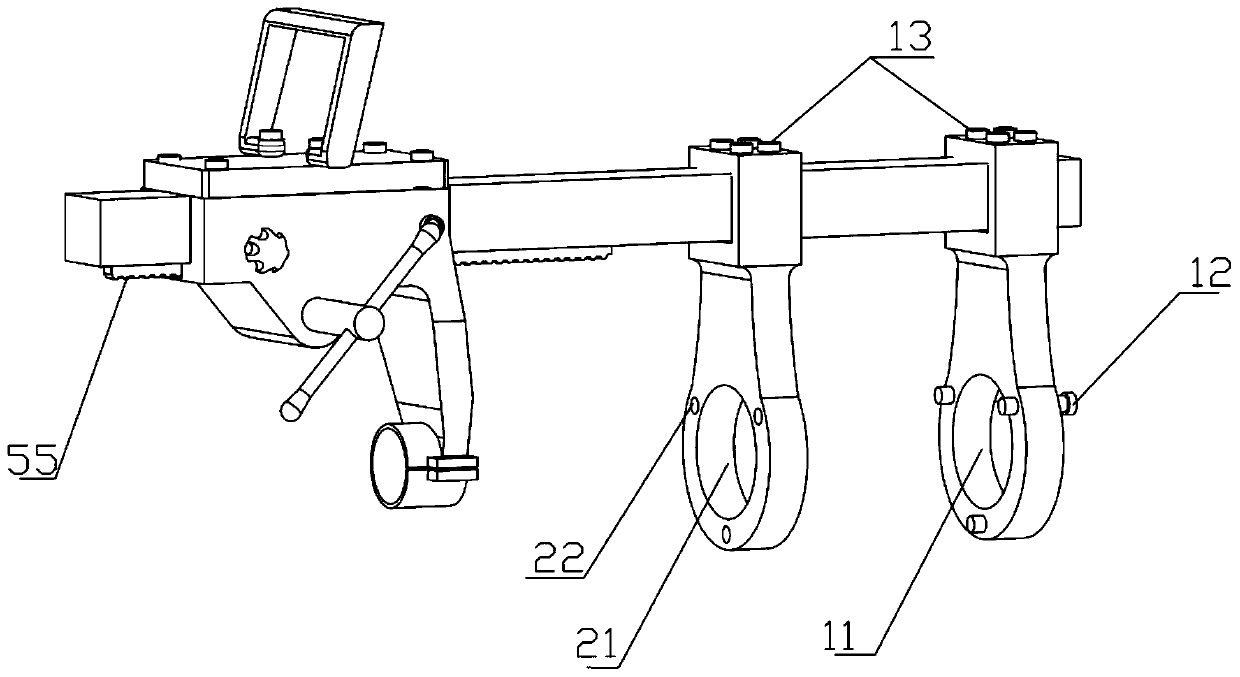

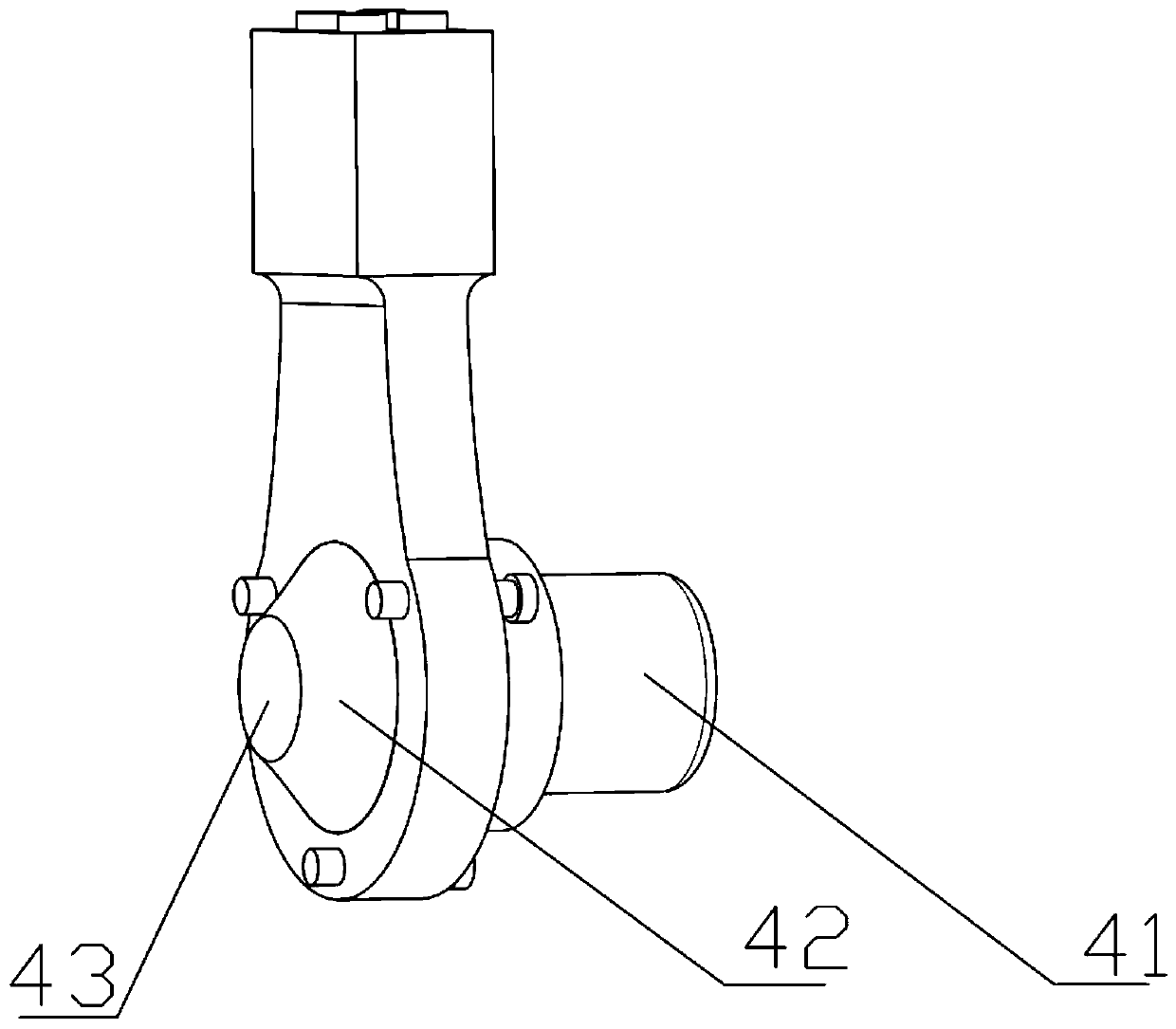

[0032] see Figure 1-5, this embodiment 1 discloses a tower crane lug plate boring machine, which is mainly composed of a positioning device and a boring device. The positioning device includes a guide rod 3, a first positioning plate 1, a second positioning plate 2, a The tops of a positioning plate 1 and the second positioning plate 2 are provided with mounting holes, and the two positioning plates are vertically sleeved on the guide rod 3 through the mounting holes. Four fastening bolts 13 are respectively provided on the mounting holes, and the first positioning plate 1 is provided with a first positioning hole 11, and the bottom of the second positioning plate 2 is provided with a second positioning hole 21. Both the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com