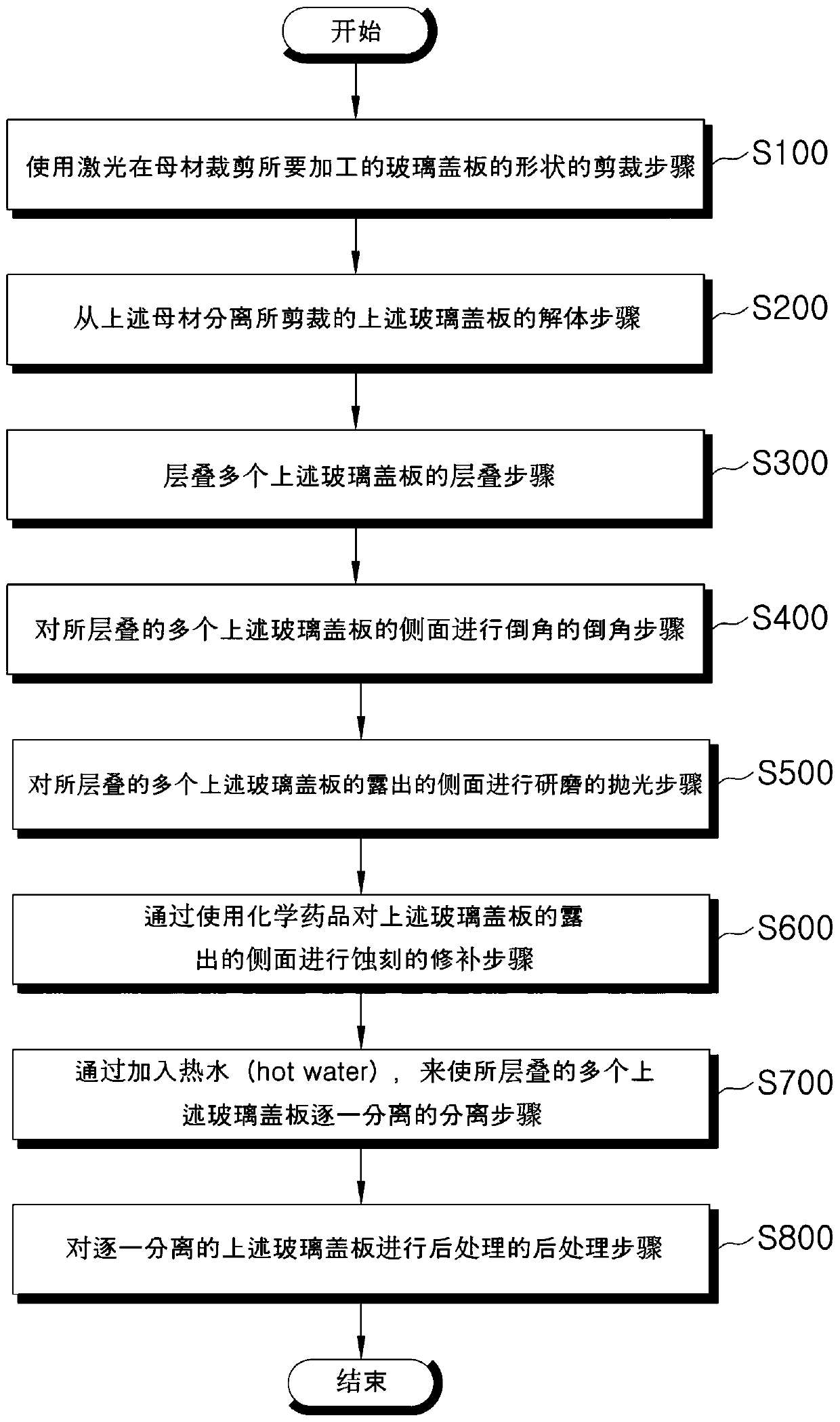

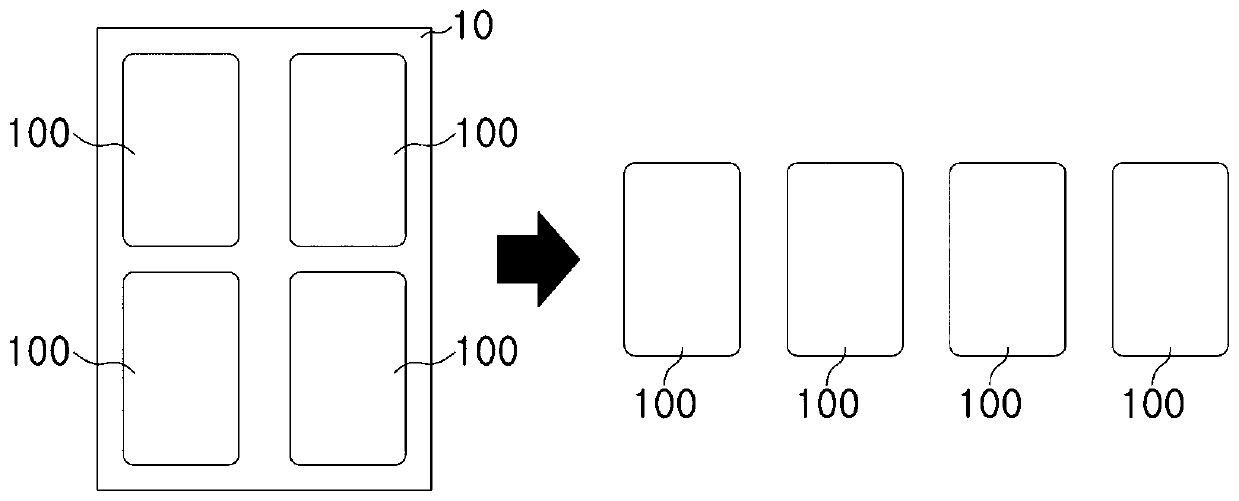

Glass manufacturing method for manufacturing thin cover glass

A glass cover plate and glass manufacturing technology, which is applied in glass manufacturing equipment, manufacturing tools, glass cutting devices, etc., can solve problems such as defective products, damage, and long manufacturing process, and achieve suppression of wear and damage, suppression of damage, and suppression of etching Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

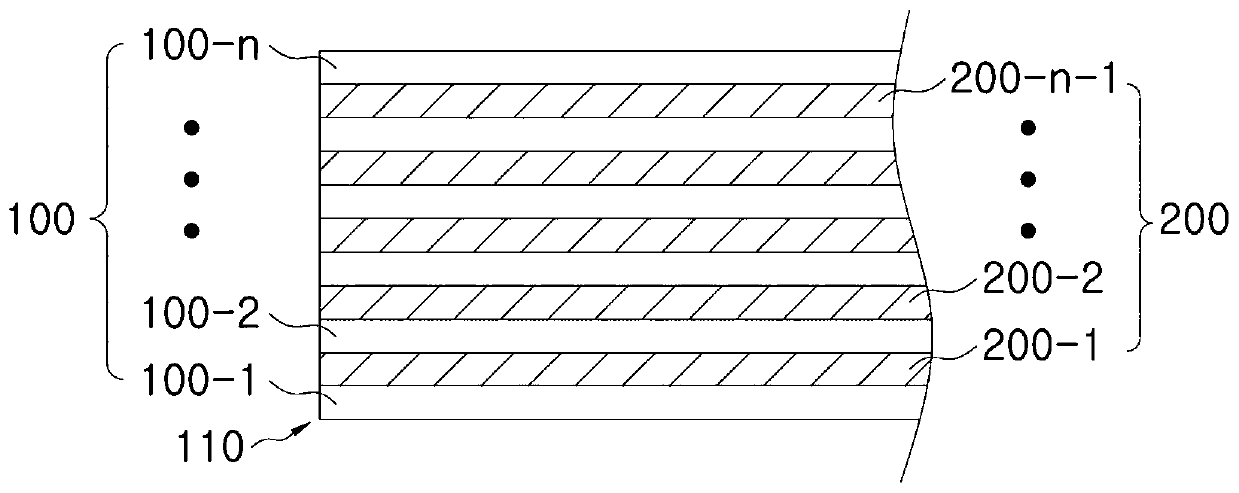

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, embodiments will be described in detail with reference to the drawings. Various modifications can be added to the embodiment, and various forms are possible, and specific embodiments are illustrated in the drawings and described in detail in this specification. However, this limits the embodiment to a specific disclosed form, and it should be understood that all changes, equivalent technical solutions, or replacement technical solutions within the idea and technical scope of the embodiment are included.

[0027] Terms such as 'first' and 'second' are used to describe various structural elements, but the above structural elements are not limited to the above terms. The above terms are only used to distinguish one structural element from another structural element. In addition, the terms specifically defined in consideration of the structure and function of the embodiment are only for describing the embodiment, and do not limit the scope of the embodiment. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com