Handheld type yarn fault holographic simulation device used for spooling equipment

A simulation device, a handheld technology, applied in the field of hand-held yarn defect holographic simulation devices, can solve the problems of electronic yarn clearer production opening and product quality impact, enterprise economic loss, deviation, etc., to improve product quality and equipment development High efficiency, accurate and reliable work, satisfying the effect of parameter correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

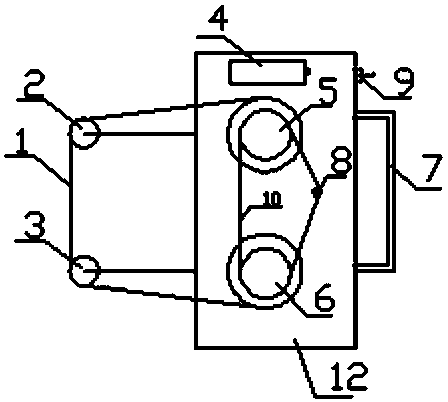

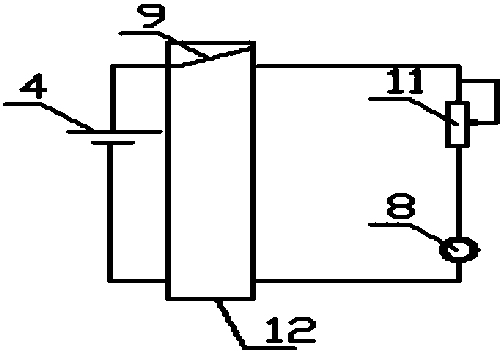

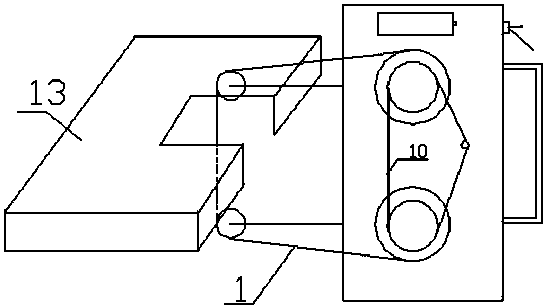

[0013] Such as figure 1 , figure 2 , image 3 As shown, the housing 12 of the present invention has a housing handle 7, and the housing 12 is fixed with a battery 4, a wire feeding wheel 5, a wire receiving wheel 6 and a driving motor 8, and the driving motor 8 drives the wire feeding wheel through a transmission belt 10. 5 and the take-up wheel 6 rotate, the front guide wheel 2 and the rear guide wheel 3 are fixed outside the housing 12, and the outer side of the housing 12 is provided with a reversible power switch 9; , the holographic simulated defective yarn 1 is recovered in the take-up wheel 6 through the front guide wheel 2 and the rear guide wheel 3; 9 is contained in the other side of housing 12, is convenient to operate. The holographic simulated defective yarn 1 is a small roll made of unqualified yarns and qualified yarns. The unqualified yarns are separated from qualified yarns. The unqualified yarns include static slubs, short and thick, short and thin, and l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com