Electric Control System of 20,000-ton Isothermal Forging Hydraulic Press

An electronic control system and hydraulic press technology, applied in the field of presses, can solve problems such as complex process actions, inability to meet the control needs of 20,000-ton isothermal forging hydraulic presses, and high requirements for electrical control systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

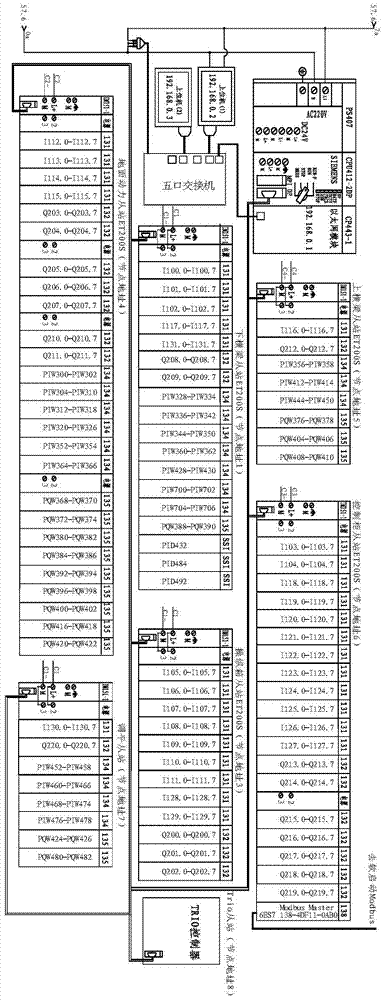

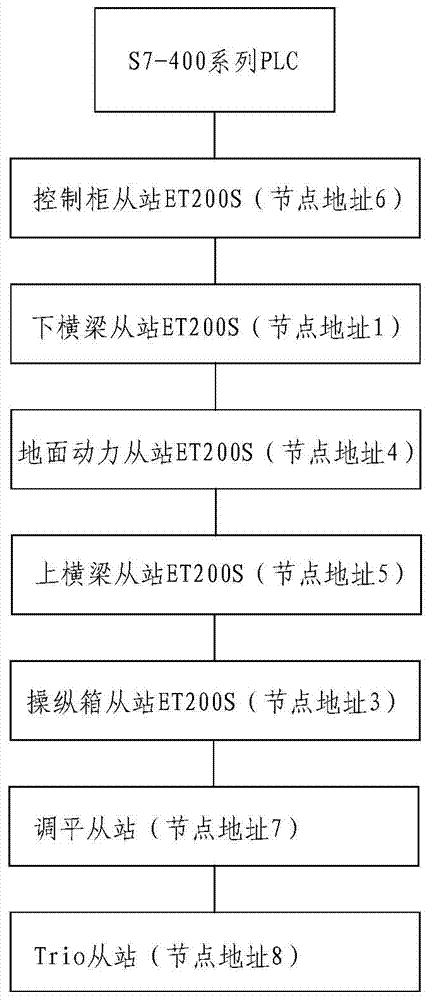

[0021] see figure 1 and figure 2 , an electronic control system for a 20,000-ton isothermal forging hydraulic press, including the following six parts:

[0022] Electrical control cabinet, operation box, lower beam slave station cabinet, power system slave station cabinet, upper beam slave station cabinet, and leveling slave station cabinet; wherein: the leveling slave station is equipped with a leveling system controller;

[0023] The electrical control cabinet is used to control the power start and stop of the 20,000-ton hydraulic press, and the signal terminals of the programmable controller are respectively electrically connected to circuit breakers, contactors and thermal relays; the electrical control cabinet consists of two sets of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com