A kind of control method of explosive spraying equipment for aero-engine

An aero-engine and explosive spraying technology, which is applied in general control systems, program control, electrical program control, etc., can solve problems such as aging of key components, difficulty in replacement, and impact on production progress, so as to reduce labor intensity, have broad application prospects, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

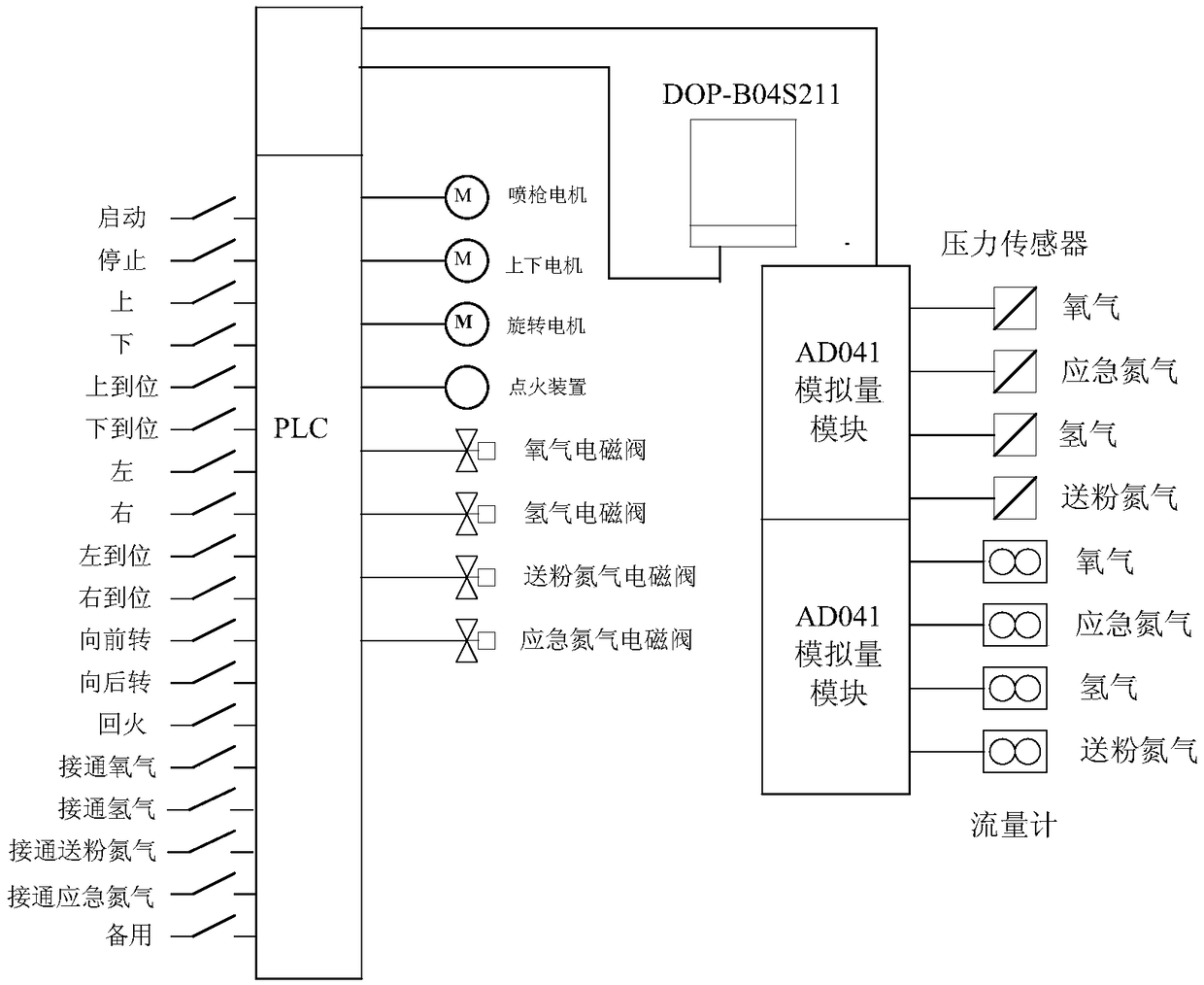

[0045] The present embodiment provides a control method for an aero-engine explosive spraying equipment, characterized in that: the control method for an aero-engine explosive spraying equipment, the program is that the control system is mainly composed of PLC, touch screen, servo system and other key parts, The hardware selection is OMRON company NS12-TS00B-ECV2, TFT12-inch touch screen, and the software is CX-Designer.ver3.2;

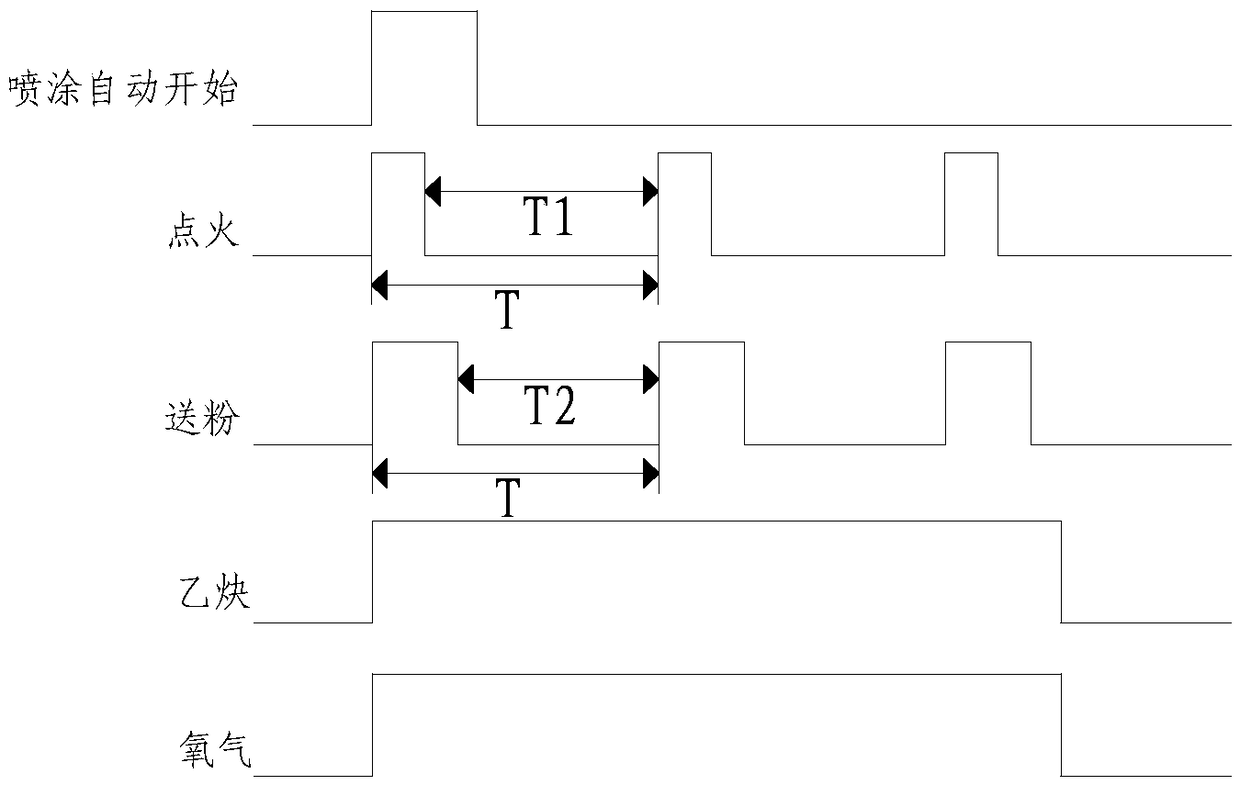

[0046] According to the relevant requirements of the explosive spraying process, the explosive spraying equipment after the transformation of the control system is a function including spraying process control, gas path flow detection and adjustment control, and spraying parameter monitoring. Corresponding controls can be performed on the operation panel and touch screen. and monitoring, the man-machine interface based on the touch screen is easy to configure and easy to operate. The system not only realizes the automatic cycle control of spraying, but...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com