Oscillating type outgoing line anti-bending connecting mechanism and mooring cable take-up and pay-off winch based on connecting mechanism

A connection mechanism and mooring cable technology, which is applied to ground devices, aircraft parts, and ground devices for mooring aircraft, and can solve problems such as affecting the reliability of mooring equipment, interruption of communication, and damage to mooring cables.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

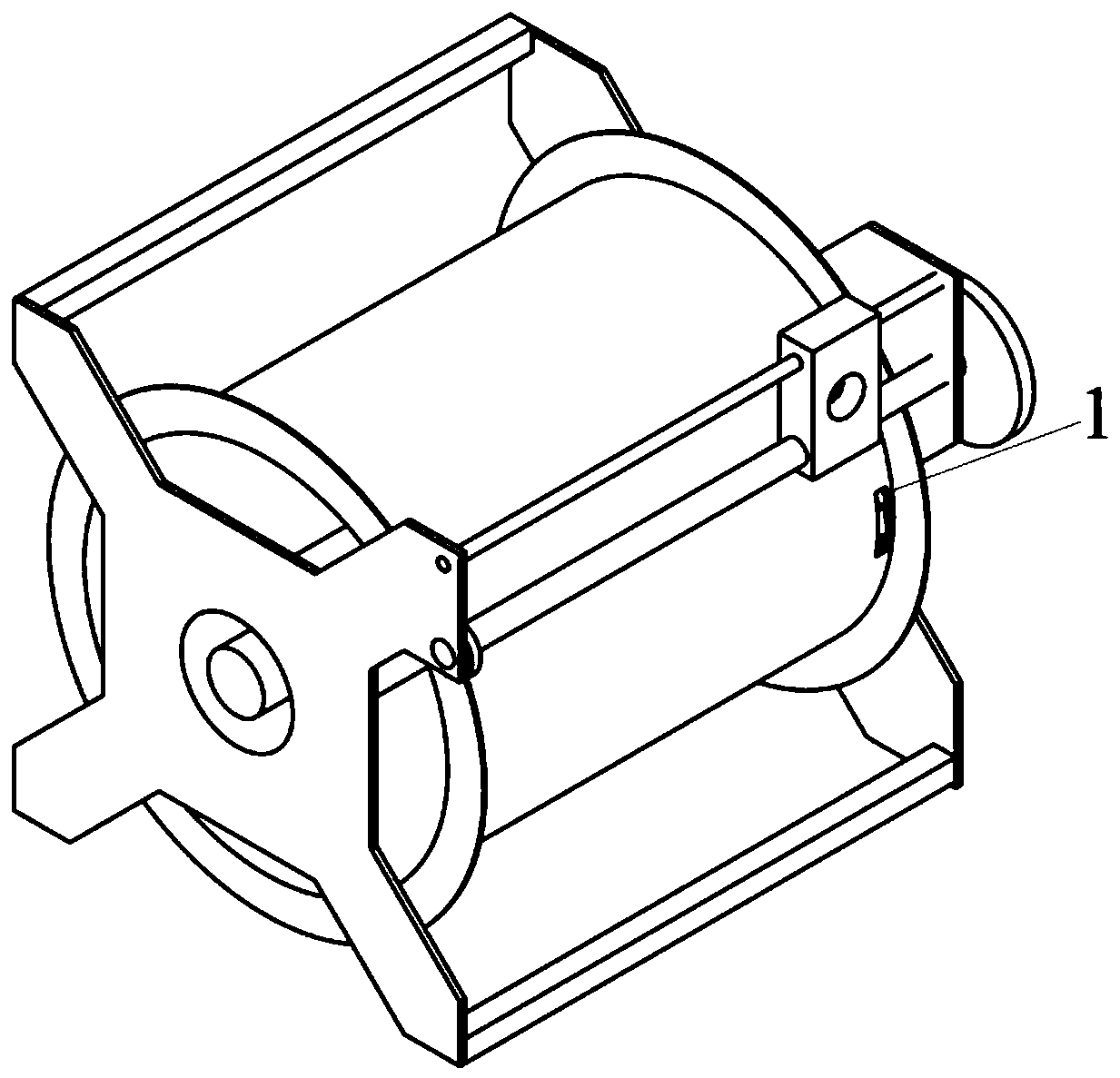

[0026] This embodiment provides a mooring cable take-up and release winch swing-type outgoing line anti-bending connection mechanism, which can solve the damage to the mooring cable caused by the sharp-angle bending when the mooring cable is paid out to the end, and ensure the safety of the mooring equipment. work reliability.

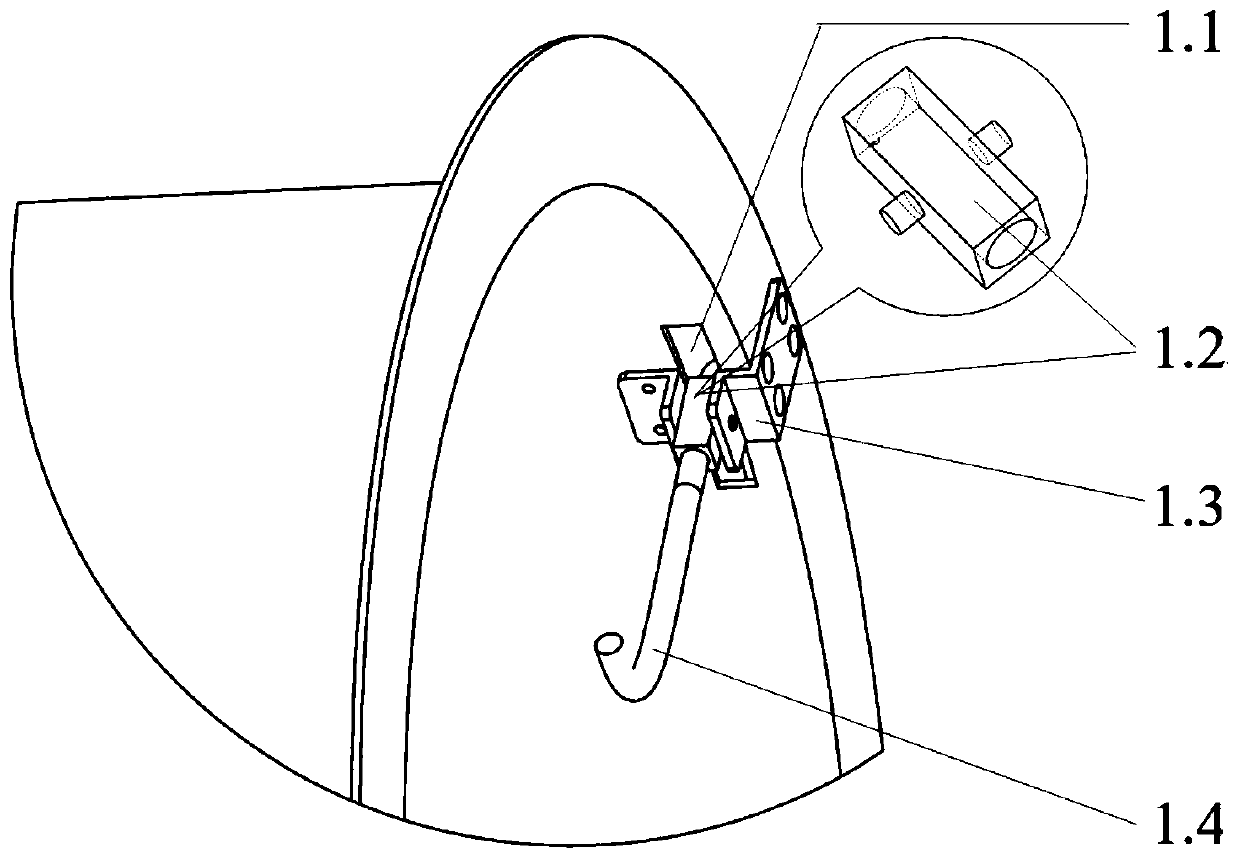

[0027] Such as figure 1 and figure 2 As shown, the swing-type outgoing line anti-bending connection mechanism 1 is arranged at the corresponding position of the wire passing hole inside the winding drum, including: a wire harness sleeve 1.2 and a wire harness sleeve central axis bracket 1.3, wherein the center of the wire harness sleeve 1.2 The through hole is used to pass the mooring cable through, and the two opposite sides of the outer surface of the wire harness sleeve 1.2 are provided with a rotating shaft perpendicular to the axis of the central hole; the mooring cable winding drum 2 is processed with an outlet elongated hole 1.1; The central ...

Embodiment 2

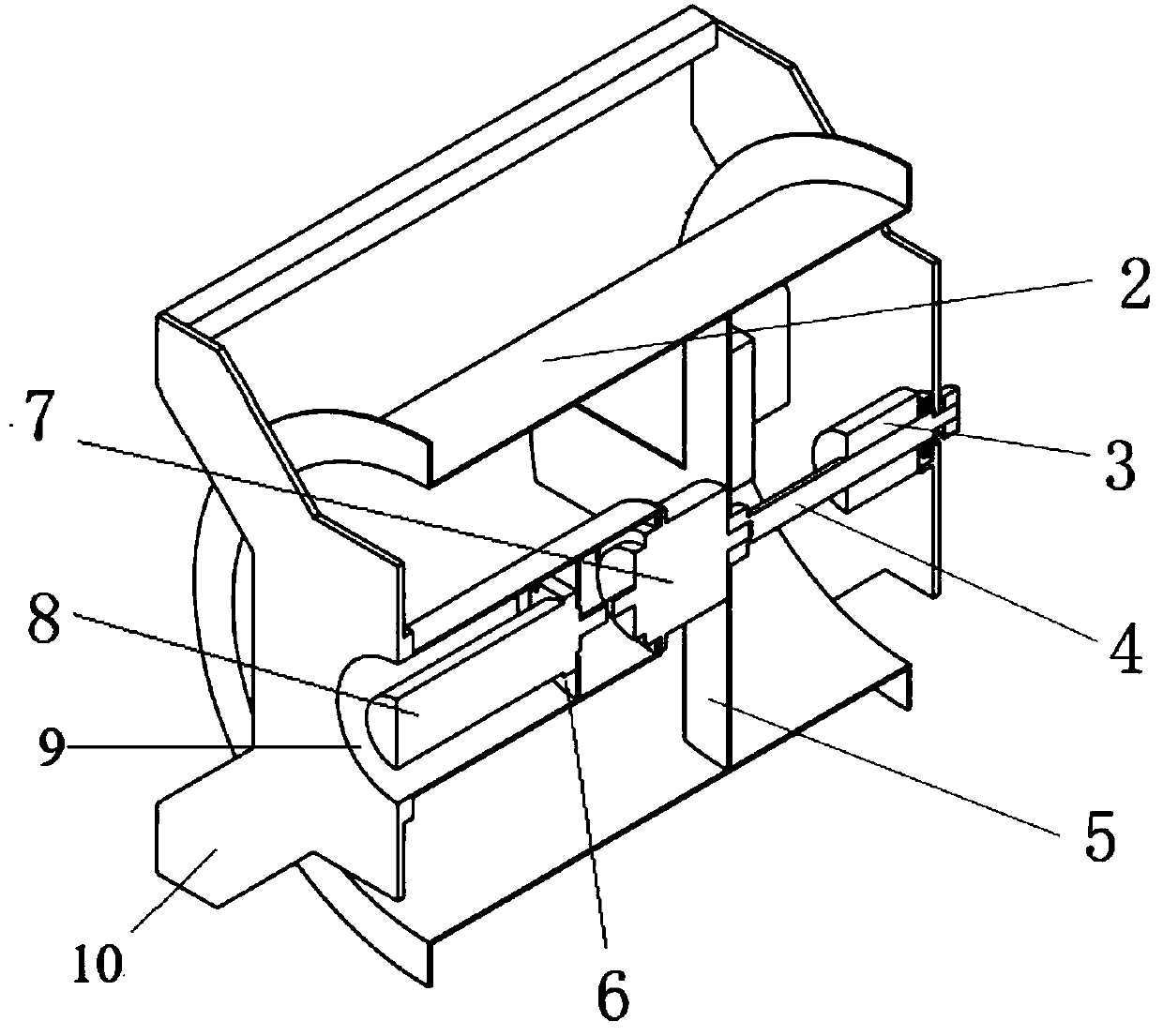

[0031] This embodiment provides a compact moored cable take-up and pay-off winch provided with the swing-type outgoing line anti-bending connection mechanism in the first embodiment above. The take-up and pay-off winch improves the structure of the traditional take-up and pay-off winch, for example, the drive motor, electromagnetic clutch and other components are built into the inner space of the originally idle tethered cable winding drum, and at the same time, the related belt drive is omitted or simplified. Mechanism, shafting support, panel, cover and winch conjoined base, etc., thereby greatly reducing the overall volume and overall weight of the pay-off winch, making its structure more compact.

[0032] image 3 As shown, the compact moored cable take-up and pay-off winch includes: moored cable winding drum 2 , cable assembly, cross-spoke drum transmission support 5 , motor 8 , electromagnetic clutch 6 and winch support 10 .

[0033] The connection relationship is: the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com