Large-range wall painting device for building

A large-scale, architectural technology, applied in the direction of construction, building structure, etc., can solve the problems of limited stroke of the lifting device and small painting range, and achieve the effect of large range and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

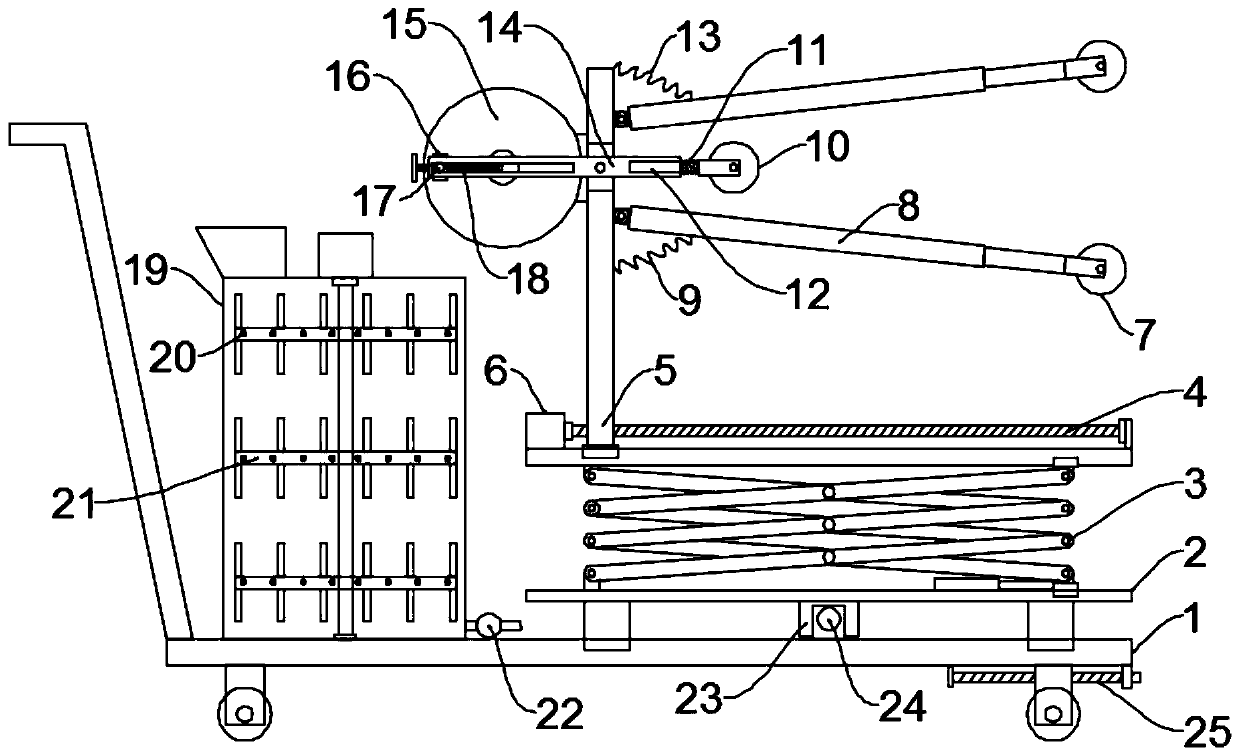

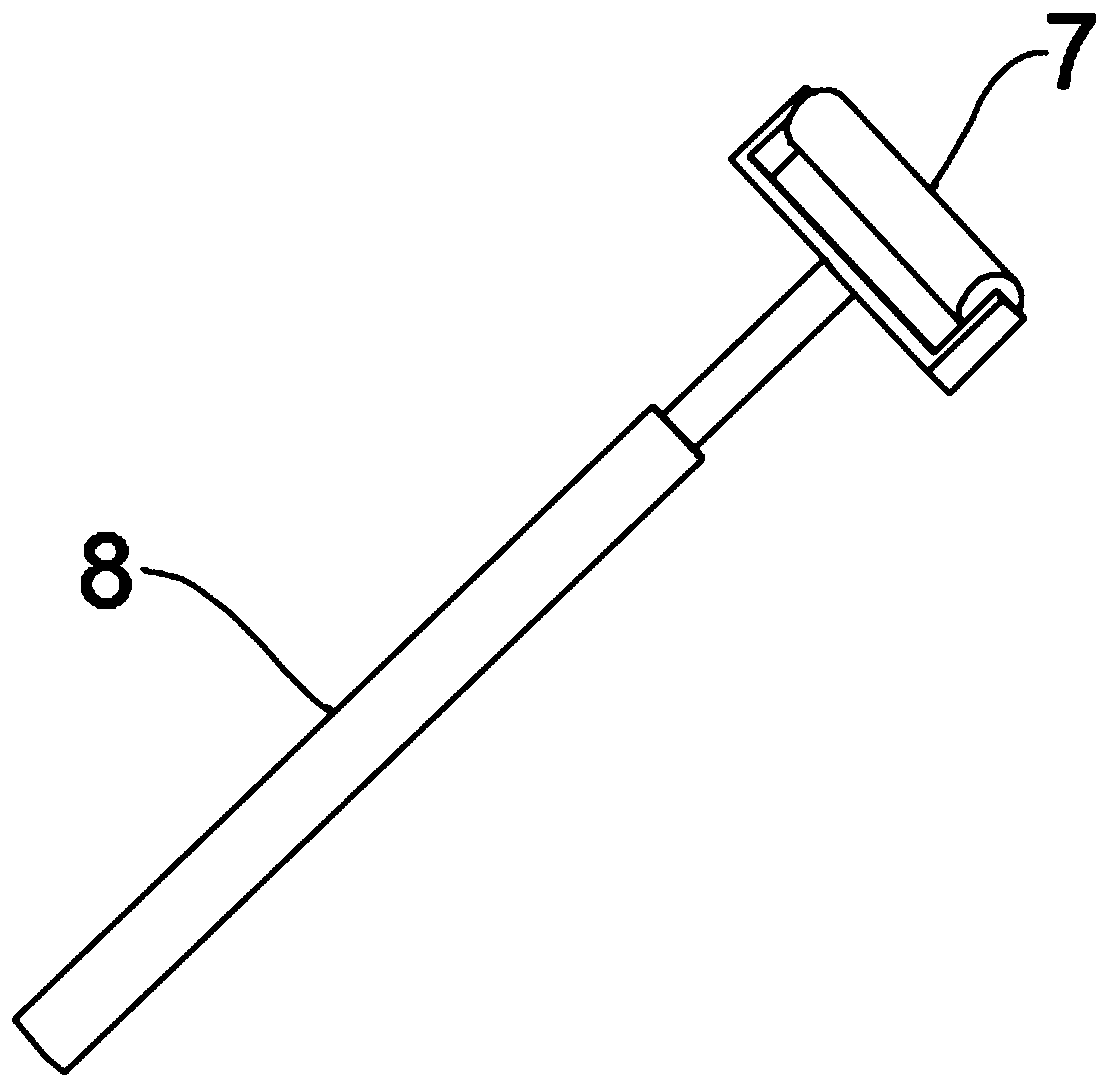

[0023] see Figure 1~2 , in an embodiment of the present invention, a large-scale wall painting device for construction includes a trolley 1, a paint supply unit installed on the trolley 1, and a painting unit, and the paint supply unit includes a preparation cylinder 19 and a stirring assembly 21 and a supply pipe, the top of the preparation cylinder 19 is provided with a feed inlet, the bottom is connected with a supply pipe, and a booster pump 22 is installed on the supply pipe, and the stirring assembly 21 includes a stirring shaft, a stirring rod and is used to drive the stirring shaft to rotate The stirring motor, the stirring shaft is installed in the preparation cylinder 19 for rotation, the stirring shaft is located on the shaft section in the preparation cylinder 19 and rotates from top to bottom to install a plurality of stirring rods, and the stirring rods are fixedly installed with The stirring rod has a wave-shaped hole 20 on the stirring rod, and the stirring sh...

Embodiment 2

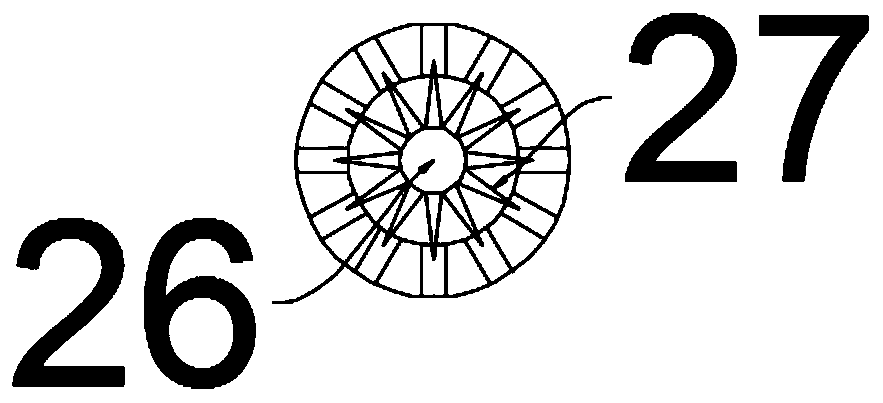

[0026] see image 3 The difference between the embodiment of the present invention and embodiment 1 is that the first painting roller 7 and the second painting roller 10 are provided with an air bag 26, and the air bag 26 is integrally provided with a nozzle extending into the spray hole. The adjustment protrusion 27, the air bag 26 is connected with a connecting pipe, and a valve is installed on the connecting pipe, and the volume of the adjustment protrusion 27 can be adjusted by inflating or deflating the air bag 26, thereby adjusting the size of the nozzle hole to meet different painting requirements. Adaptable.

[0027]The working principle of the present invention is: when working, the height is adjusted by the lifting mechanism, and then the second forward and reverse motor 6 drives the third mounting plate 5 close to the wall, and the two first painting rollers 7 are respectively along the upper and lower sides of the wall. until it moves to the top and bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com