Constant temperature and humidity control equipment for textile workshop

A control equipment, constant temperature and humidity technology, applied in the textile field, can solve the problems of high temperature, high humidity and poor environment in the textile workshop, and achieve the effect of eliminating fire hazards, comfortable working environment, avoiding economic losses and casualties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

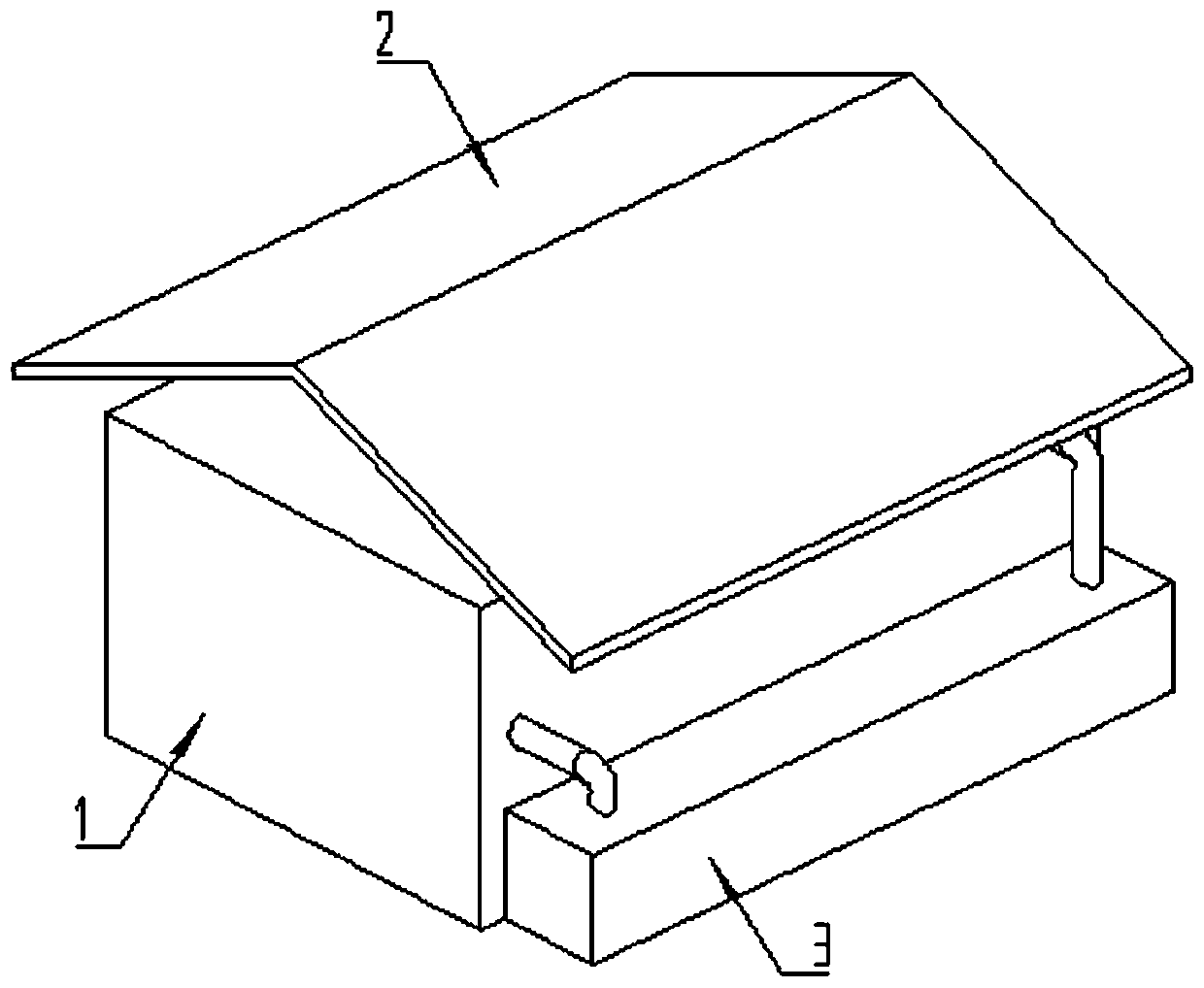

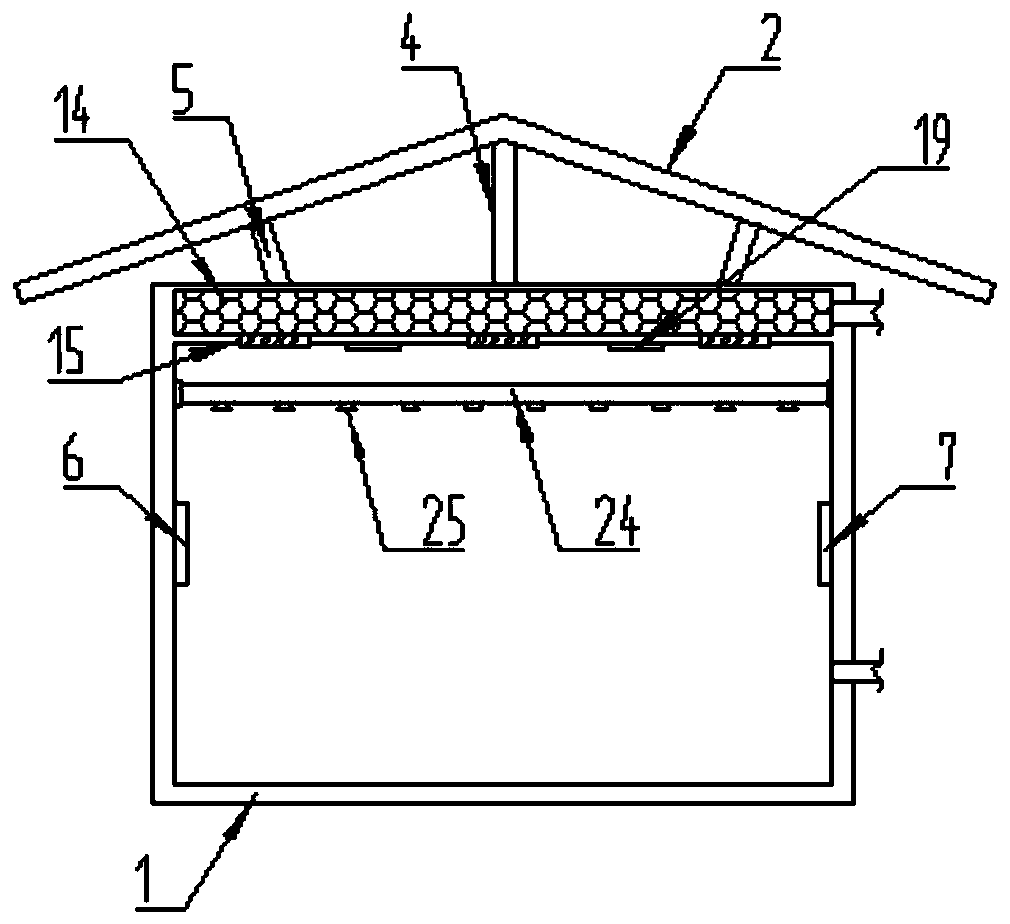

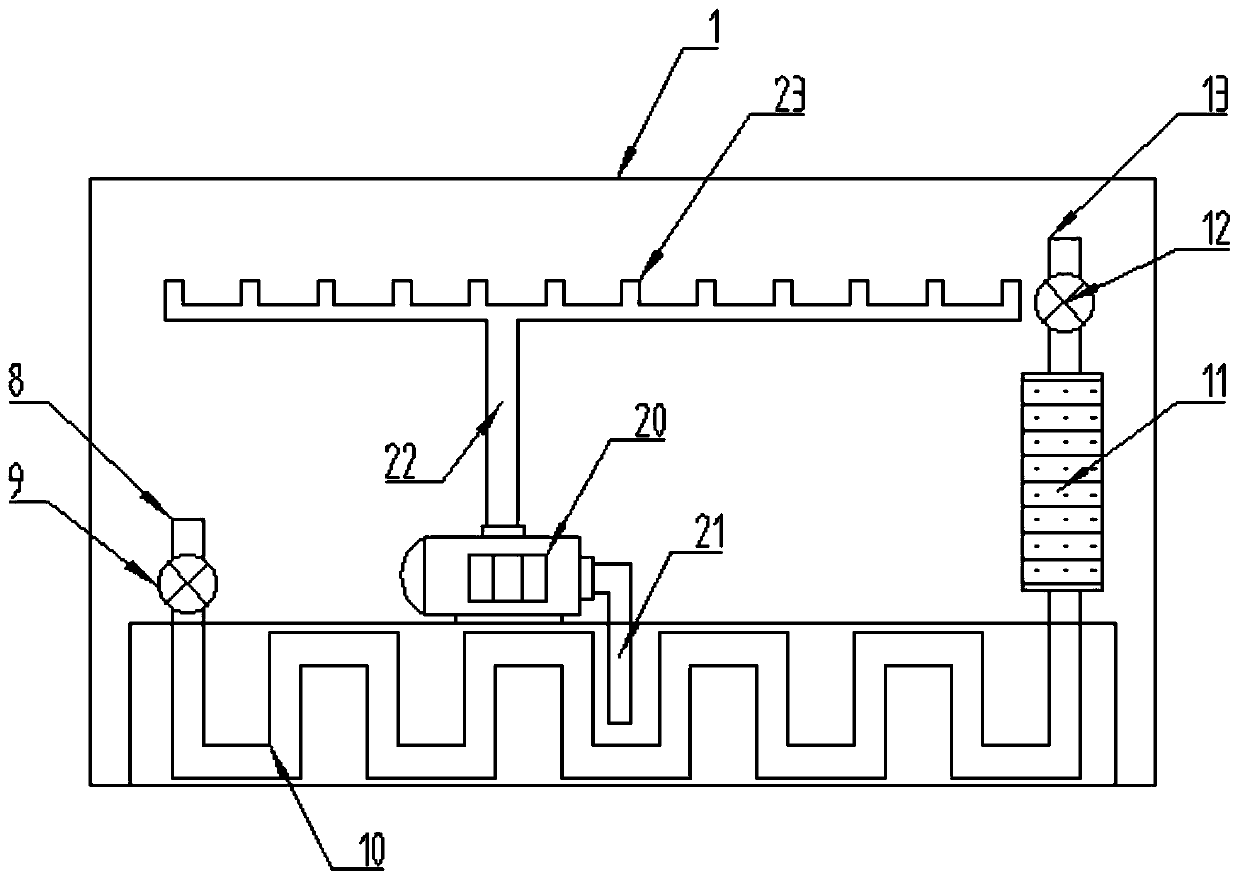

[0033] Such as Figure 1~2 As shown, the embodiment of the present invention provides a constant temperature and humidity control device for a textile workshop, the constant temperature and humidity control device includes an automatic constant temperature mechanism, an automatic constant humidity mechanism and a central controller; the automatic constant temperature mechanism includes a temperature sensor 6 , the automatic constant humidity mechanism includes a humidity sensor 7, the temperature sensor 6 and the humidity sensor 7 are installed on the left and right inner walls of the workshop 1, and the temperature sensor 6 and the humidity sensor 7 are respectively connected to the central controller; An automatic fire extinguishing mechanism is provided inside the workshop 1; a protective assembly is provided on the top of the workshop 1.

[0034] The constant temperature and humidity control equipment used in the textile workshop is specially equipped with an automatic con...

Embodiment 2

[0047] Such as Image 6 As shown, in another embodiment provided by the present invention, an automatic dust removal mechanism is installed on the side wall of the workshop 1, and the automatic dust removal mechanism includes an exhaust fan 31, and the exhaust fan 31 is installed on the side wall of the workshop 1. In the dust removal port 30, a dust removal pipe 32 is sleeved on the dust removal port 30, and the other end of the dust removal pipe 32 is connected with a dust removal bag 34, and the dust removal bag 34 is clamped on the mounting frame 33.

[0048] When the dust content in the workshop 1 is large, the exhaust fan 31 can be started, and the dust-containing air can be drawn out by the exhaust fan 31, and the dust in the air can be intercepted by the barrier of the dust removal bag 34 to achieve the purpose of dust removal. In addition, the dust removal bag 34 is in the It can be replaced in time after use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com