Reusable ejection simulation load and manufacturing method thereof

A technology for simulating loads and manufacturing methods, applied in the field of ejection, which can solve the problems of fast ejection speed, repeated use, high test cost, etc., and achieve the effect of avoiding fracture damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

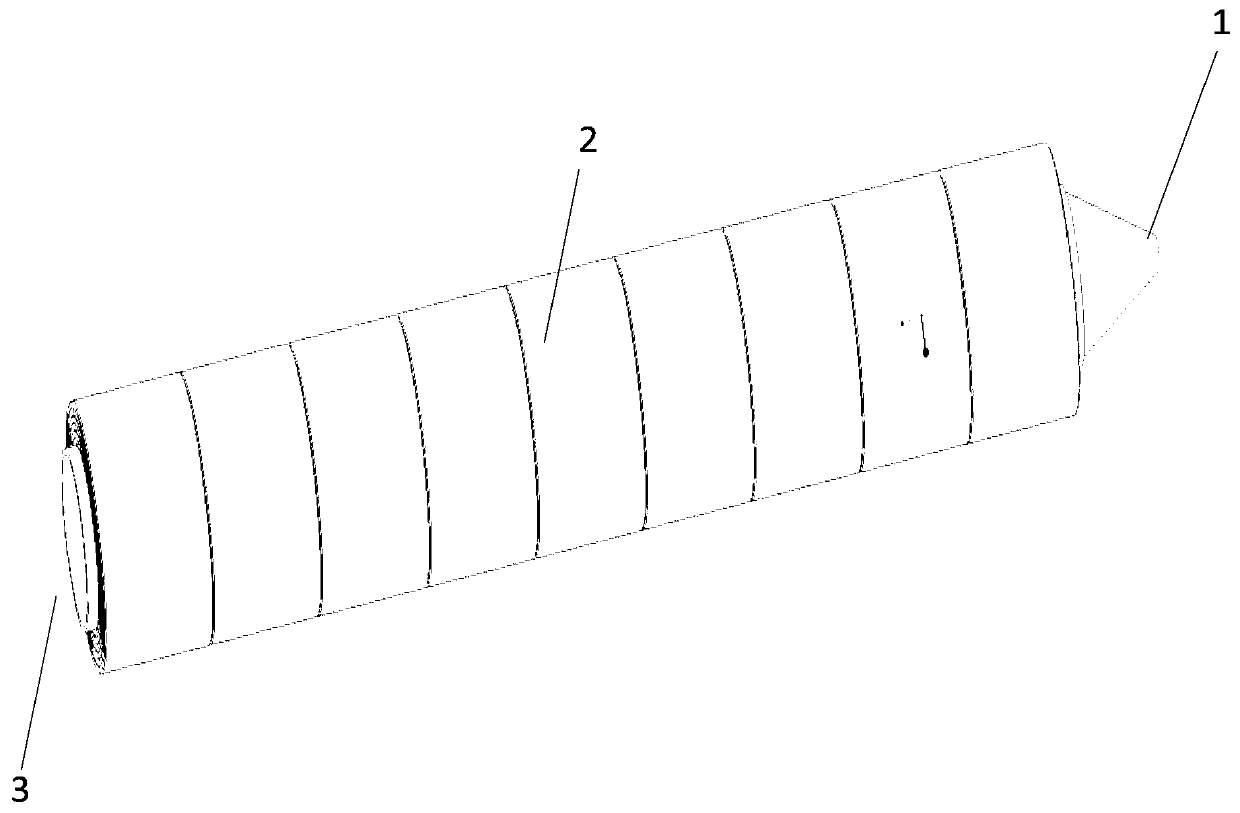

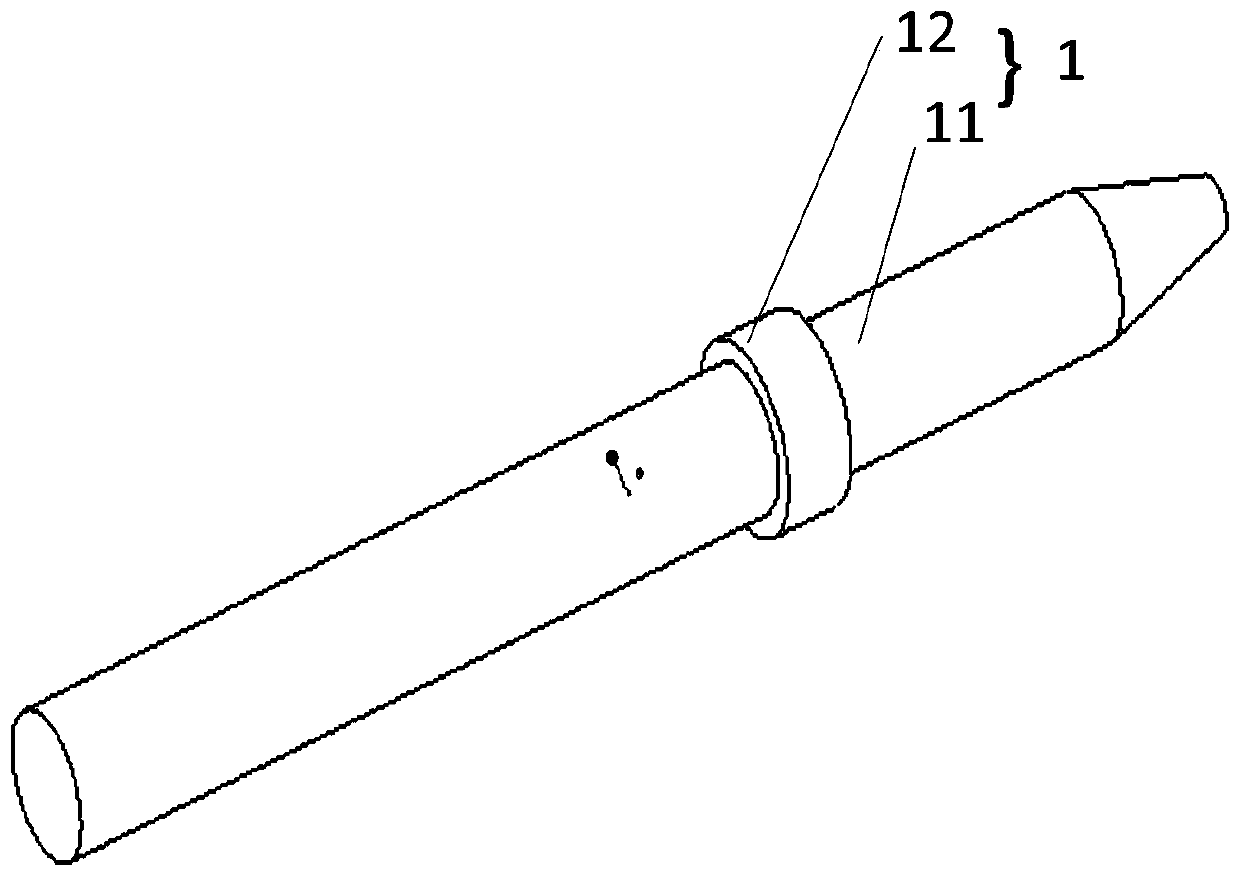

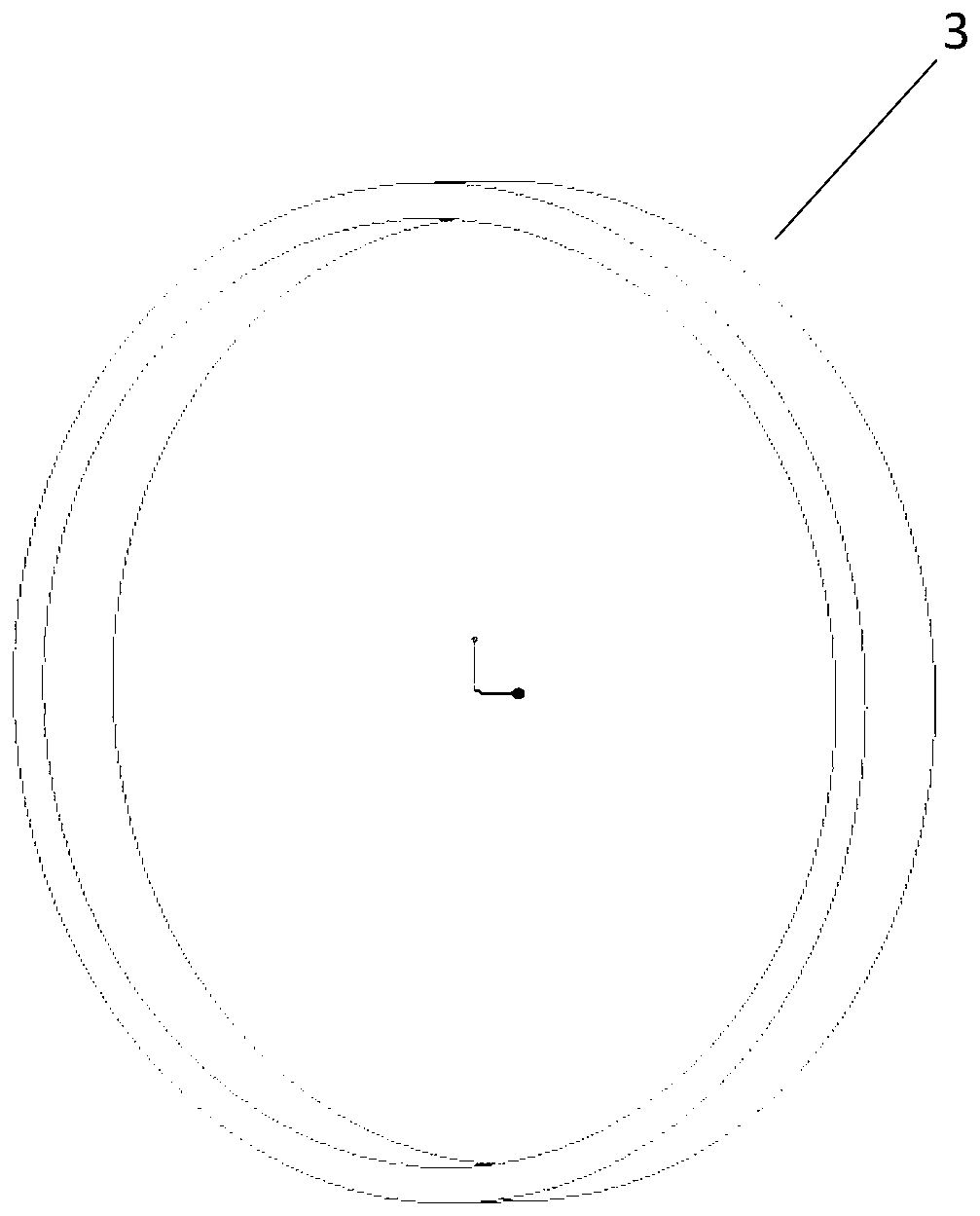

[0033] Such as figure 1 , 2 As shown in and 5, the reusable ejection simulation load of the present invention includes a load body 1, an elastic protective layer 2 and a stop structure 3, the load body 1 includes a solid body 11 and a counterweight 12, and the counterweight 12 Set and fix on the predetermined position on the solid body 11 according to the requirements of the center of mass of the simulated load, the elastic protection layer 2 is fixedly arranged on the outer surface of the load body 1 and is stably fixed on the load body 1 by the limiting structure 3 Above; wherein, there are a plurality of microporous air gaps 21 in the elastic protective layer 2 , and the elastic protective layer 2 buffers the impact force suffered ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap