Prism light guide mechanism for optical lens barrel and visual optical axis indication system

An optical lens barrel and prism technology, which is applied in the field of prism light guide mechanism and visual optical axis indication system, can solve the problems of affecting the experimental effect, large randomness, and quantitative control, so as to improve the experimental efficiency, reduce the experimental error, Avoid over-rotation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

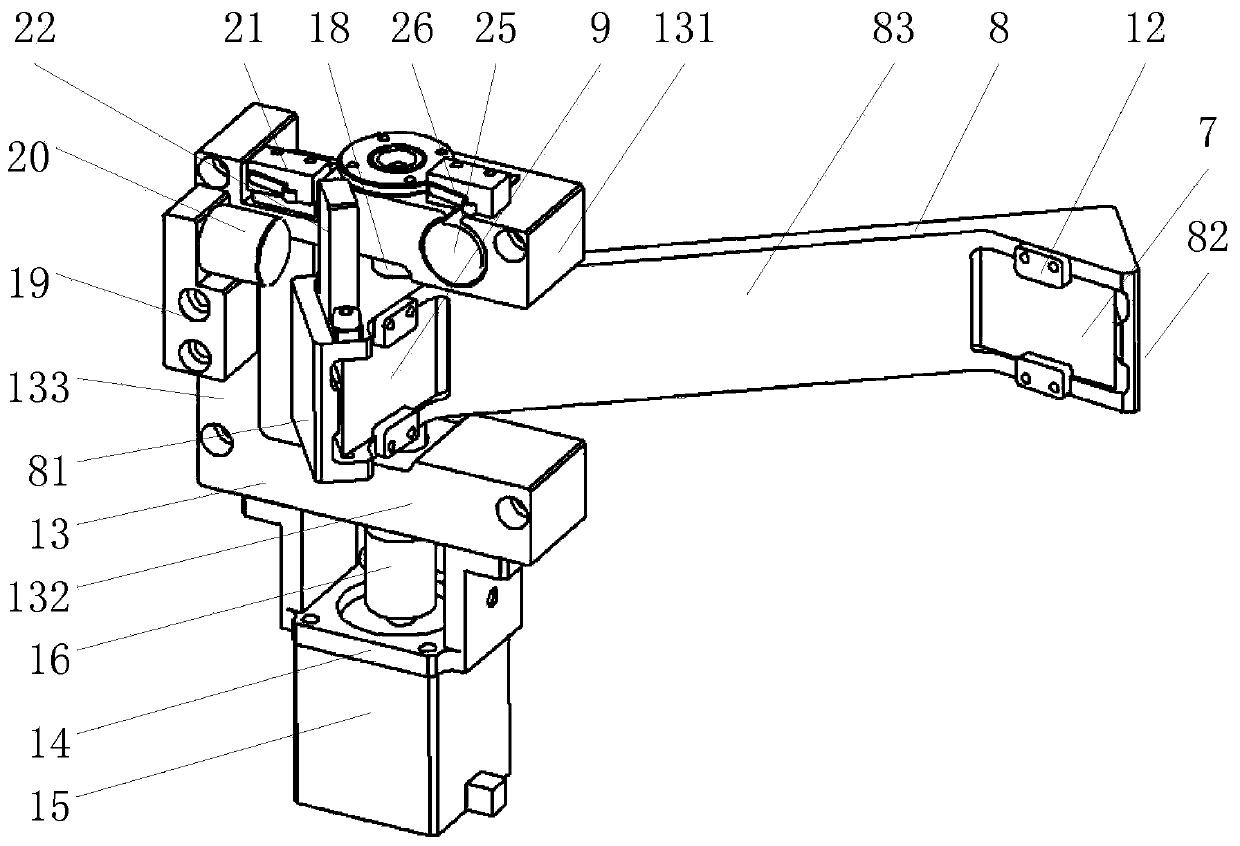

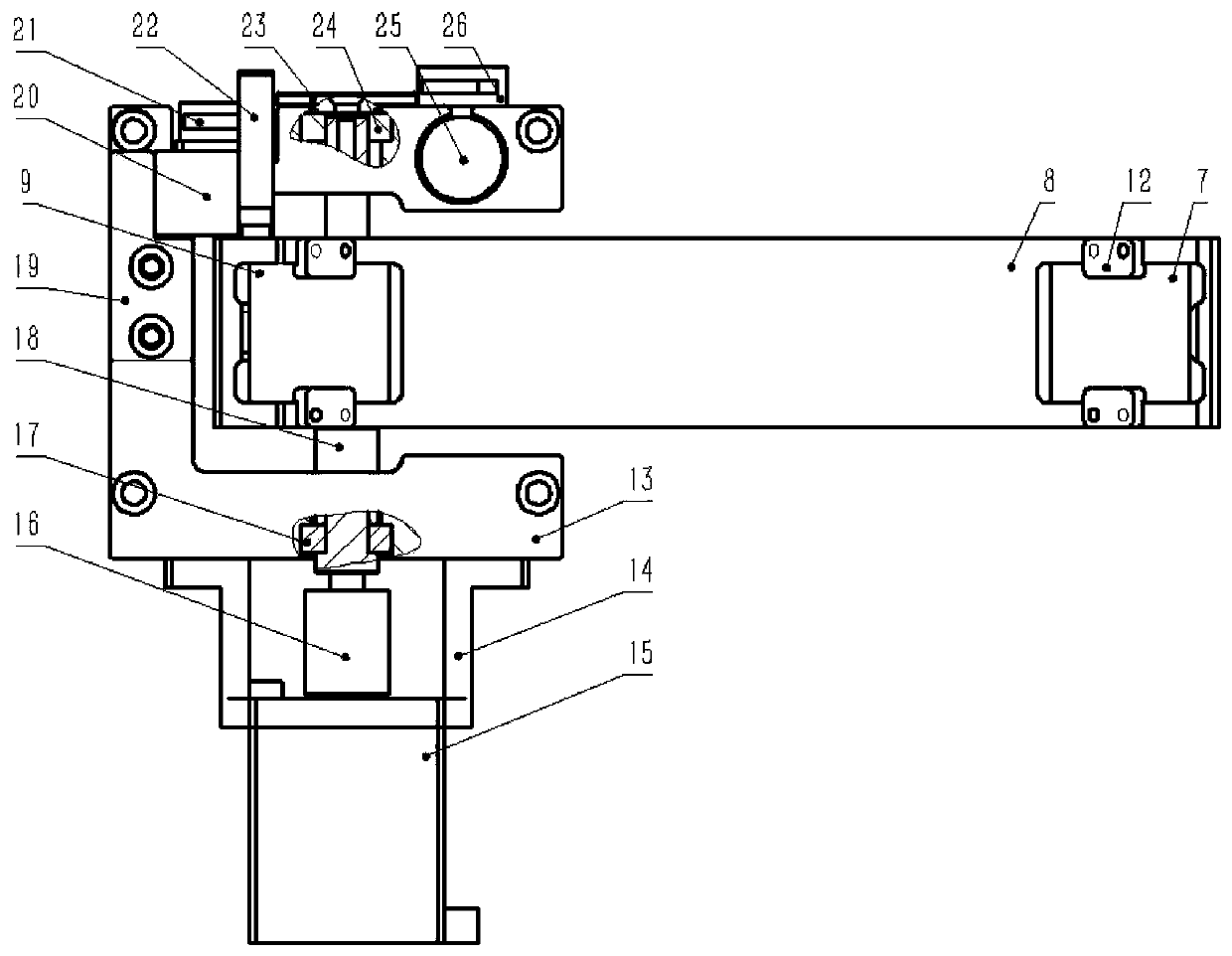

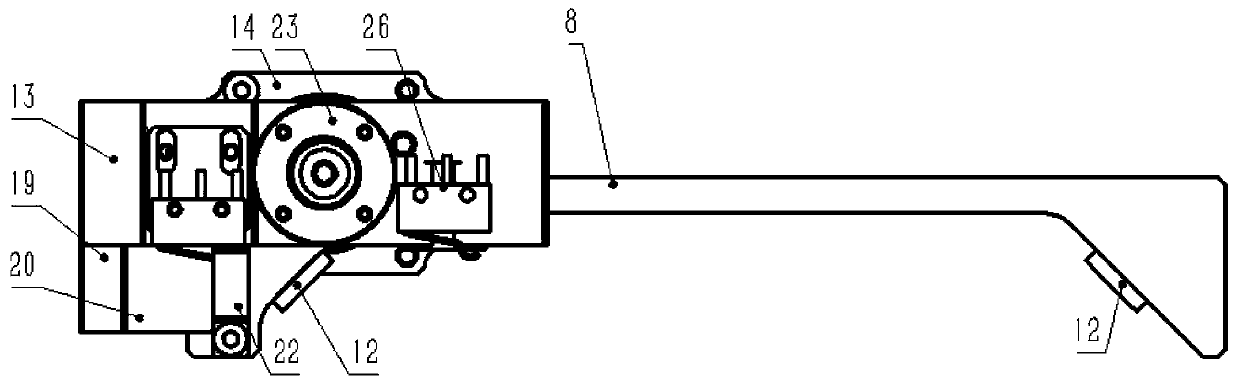

[0055] A prism light guide mechanism for optical lens barrel, such as figure 1 As shown, it includes a reflector group mount 13, a prism mount 8 and a rotating motor 15;

[0056] Such as figure 2 As shown, the reflector group mount 13 includes a first parallel plate 131 and a second parallel plate 132 parallel to each other, and a vertical plate 133 arranged at one end of the first parallel plate 131 and the second parallel plate 132; the first parallel plate 131 A rotating shaft 18 is arranged between the second parallel plate 132; the rotating shaft 18 is rotatably connected with the first parallel plate 131 through the rear bearing 24 to reduce the frictional force of rotation. The outer side of the first parallel plate 131 is provided with the rear bearing 24 Cooperating bearing end cover 23; rotatably connected with the second parallel plate 132 through the front bearing 17; the second parallel plate 132 is provided with a motor mounting frame 14; the rotating motor 15 ...

Embodiment 2

[0063] A visual optical axis indication system for optical barrels, combined with Figure 5 , Image 6 As shown, it can be used to indicate an optical lens 1. The optical lens 1 is provided with an optical lens barrel 2, and the inner wall of the rear end of the optical lens barrel 2 is provided with a second substrate; The optical pinhole 3 corresponds to the central optical axis 10 of the optical lens barrel 2; the outer wall of the optical lens barrel 2 is sequentially provided with a laser 5, a first substrate and a prism light guide mechanism as in Embodiment 1; wherein the laser 5 It is a point laser, and the laser 5 is arranged on the outer wall of the optical lens barrel 2 through the laser mounting seat 4; the wall of the optical lens barrel 2 between the first substrate and the prism light guide mechanism is provided with a prism mounting frame 8 cut into or Through the cut out hole, the prism light guide mechanism is installed on the optical lens barrel 2 through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com