Method for establishing rotor stacking precision prediction model based on geometric algebra theory

A technology of geometric algebra and accuracy prediction, applied in geometric CAD, measuring devices, instruments, etc., can solve the problems of concentricity and unbalance, low calculation efficiency of accuracy prediction model, small concentricity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] Taking a certain type of rotor with N=4, m=36, the radial runout and end face runout data of each stage of the aeroengine rotor is used as an example to calculate, the process is as follows.

[0075] S1. Use the existing iMap4 comprehensive measurement and assembly platform of a certain company to measure a certain type of rotor parts, and obtain the radial runout data of the bottom spigot, the radial runout data of the top spigot, and the runout data of the upper and lower end faces; measure the height H of each part k and mass M k .

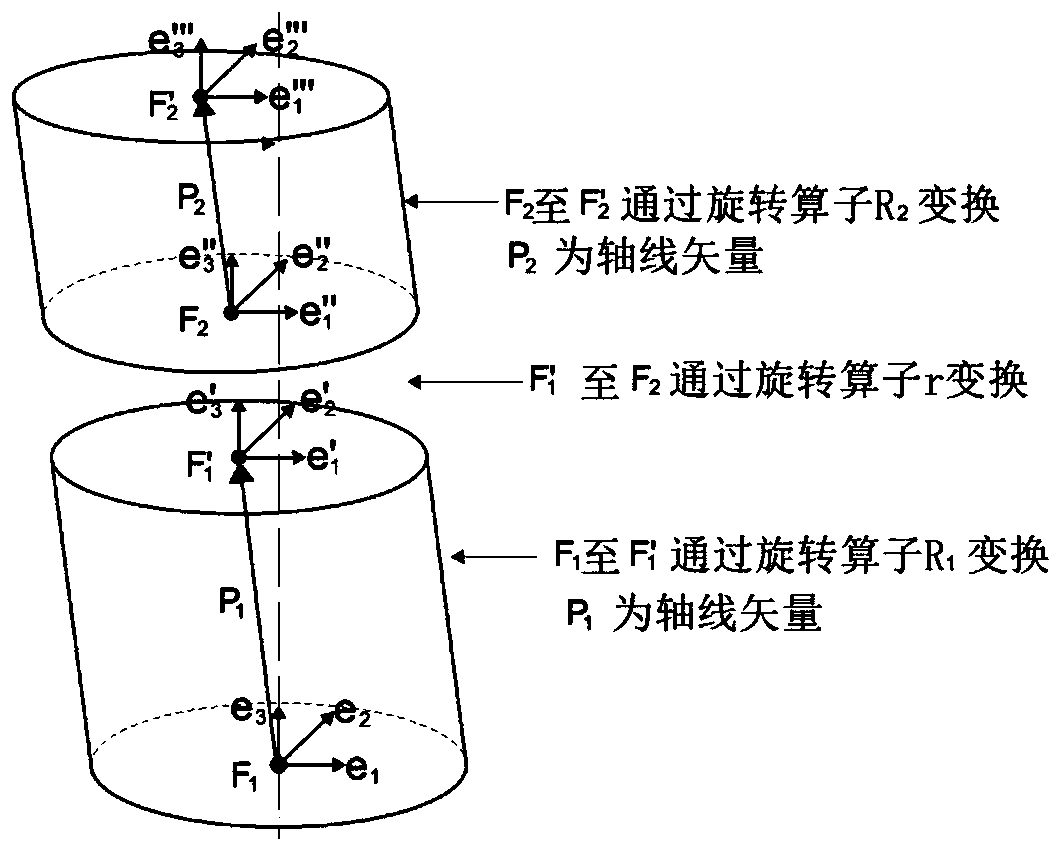

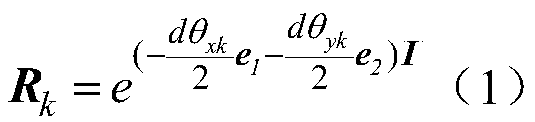

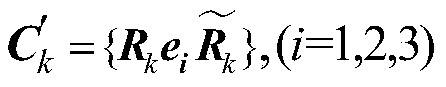

[0076] S2. Determine the pose parameters of the rotors at all levels before assembly

[0077] According to the measurement data in S1, use the least square method to calculate the center and plane equation of the upper and lower end faces of the rotors, and calculate the center of the upper and lower end faces through the radial runout data of the bottom spigot, the radial runout data of the top spigot and the height of the parts. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com