A method for detecting defects of catenary support components

A technology for supporting components and detection methods, applied in computer parts, image analysis, image enhancement, etc., to achieve the effects of improving detection efficiency and accuracy, high correct detection efficiency, and simplifying difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

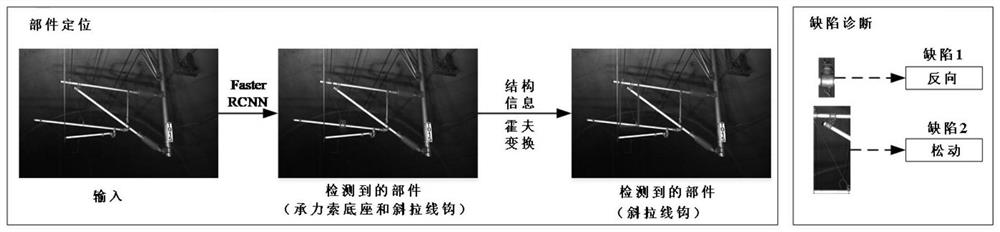

[0045] like figure 1 As shown, a method for detecting defects of catenary support components includes the following steps:

[0046] Step 1: Build a dataset of catenary cable bases and cable-stayed hooks;

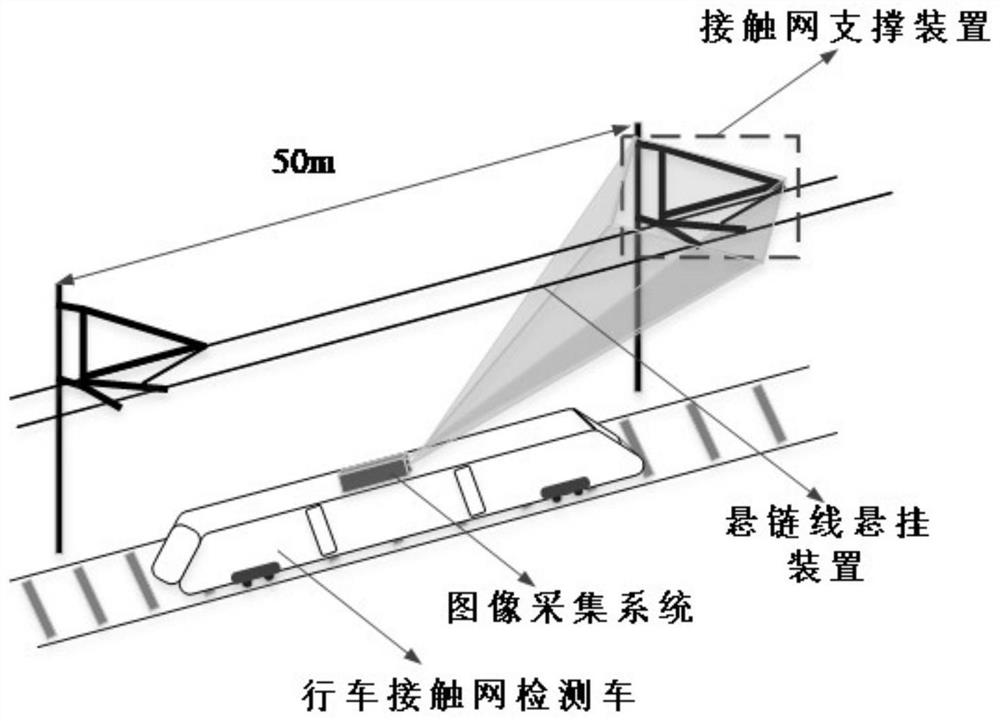

[0047] The support and suspension devices of the catenary of the high-speed railway were imaged by the special train comprehensive inspection vehicle, and the data set of the catenary bearing cable base and the cable-stayed hook was established.

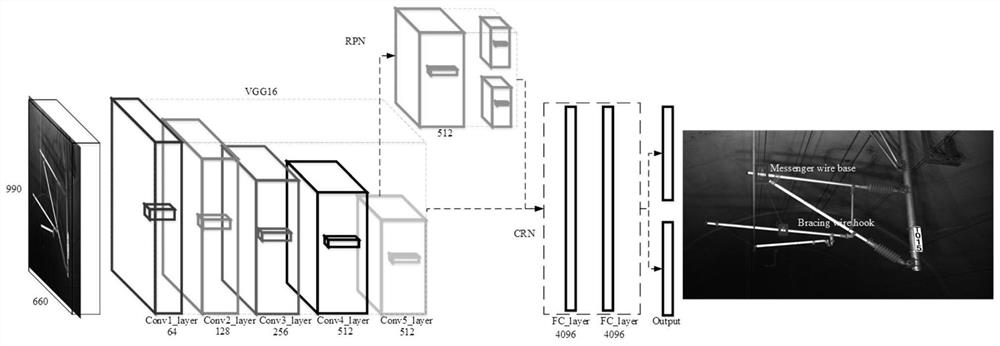

[0048] Step 2: Use the Faster RCNN convolutional neural network to locate the target, and obtain the location results of the catenary load-bearing cable base and the cable-stayed hook;

[0049] The specific process is as follows:

[0050] S11: Perform a convolution operation on the input image to obtain a feature map;

[0051] S12: Extract the RoI (RoI, Region of Interests) through the Region Prop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com