A fault-tolerant control system and control method for a series system of four DC motors

A DC motor, fault-tolerant control technology, applied in the control system, motor speed or torque control, multiple motor speed adjustment, etc., can solve problems such as low work efficiency, failure to realize fault diagnosis, large torque ripple, etc. To achieve the effect of improving the degree of non-difference, speeding up the system response, and stabilizing the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

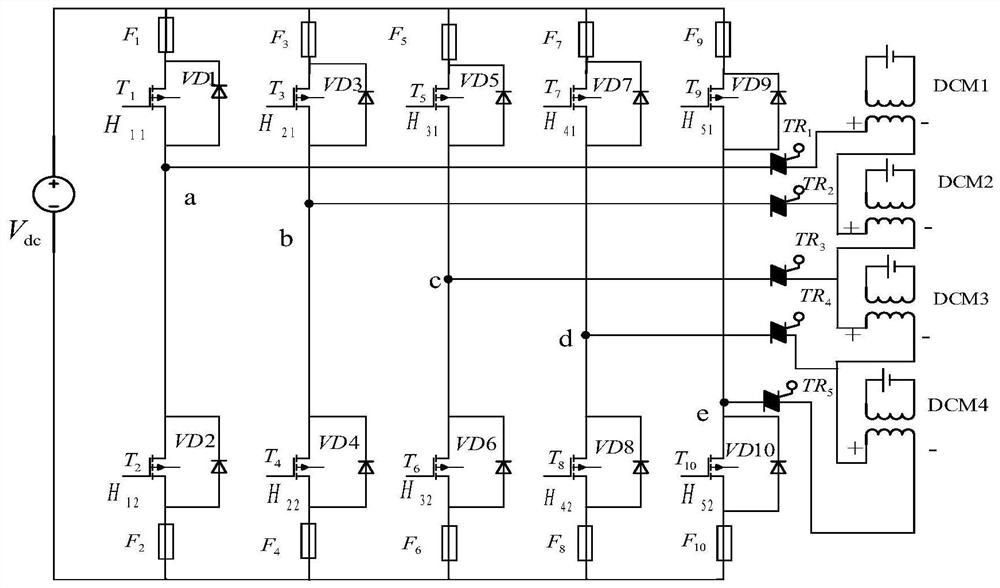

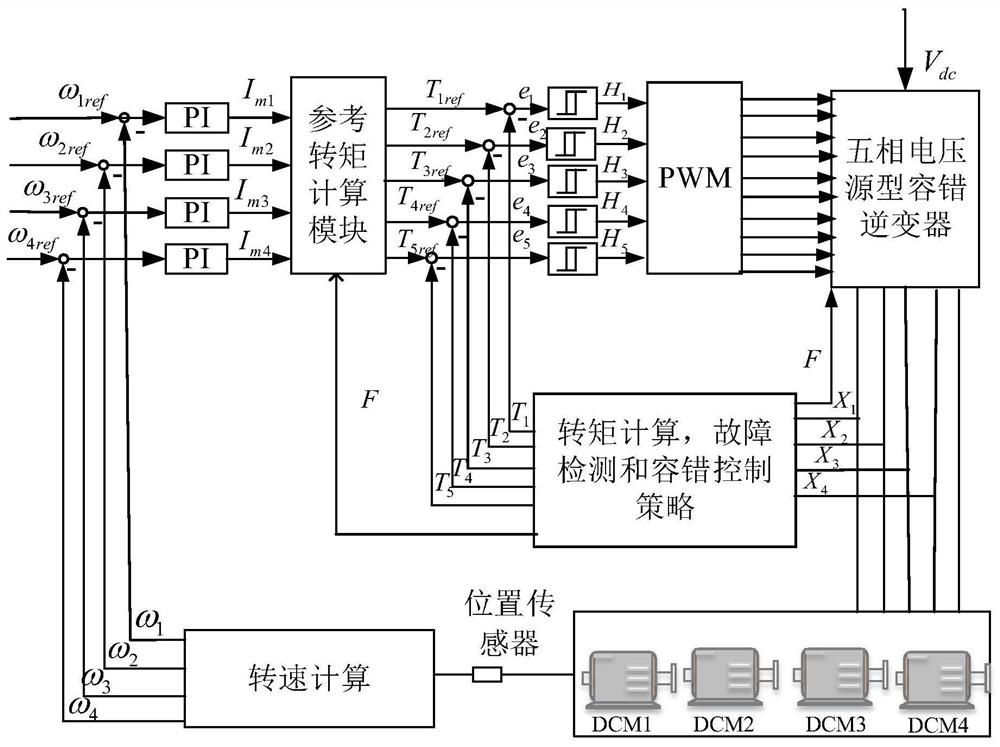

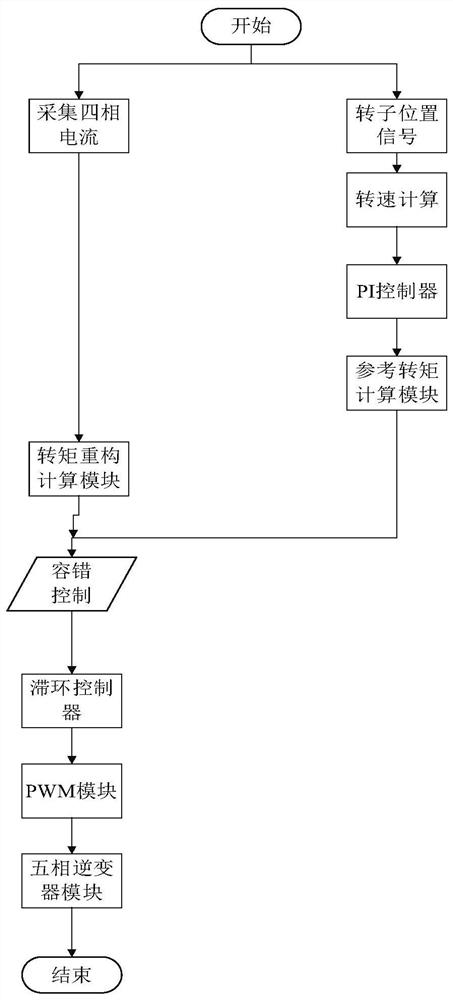

[0089] This embodiment provides a fault-tolerant control system for a series system of four DC motors. The power supply is powered by a DC voltage source. The first DC motor DCM1, the second DC motor DCM2, the third DC motor DCM3 and the fourth DC motor DCM4 adopt The five-phase inverter working bridge arm is driven, and the five-phase inverter working bridge arm includes ten switch inverter drives; each inverter working bridge arm includes two series-connected power MOS switch tubes and fuses , the upper bridge arm T in the working bridge arm of the first inverter 1 and the first fuse F 1 connection, the upper bridge arm T in the working bridge arm of the second inverter 3 and a third fuse F 3 connection, the upper bridge arm T in the working bridge arm of the third inverter 5 and the fifth fuse F 5 connection, the upper bridge arm T in the working bridge arm of the fourth inverter 7 and the seventh fuse F 7 connection, the upper bridge arm T of the fifth inverter worki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com