Coating raw material feeding bin

A technology for feeding bins and raw materials, which is applied in the direction of filters, grids, mixers, etc., can solve the problems of low coating production quality and uncontrolled particle size, and achieve the effects of improving product quality, avoiding insufficient dissolution, and avoiding precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and functions achieved by the present invention clearer and easier to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments:

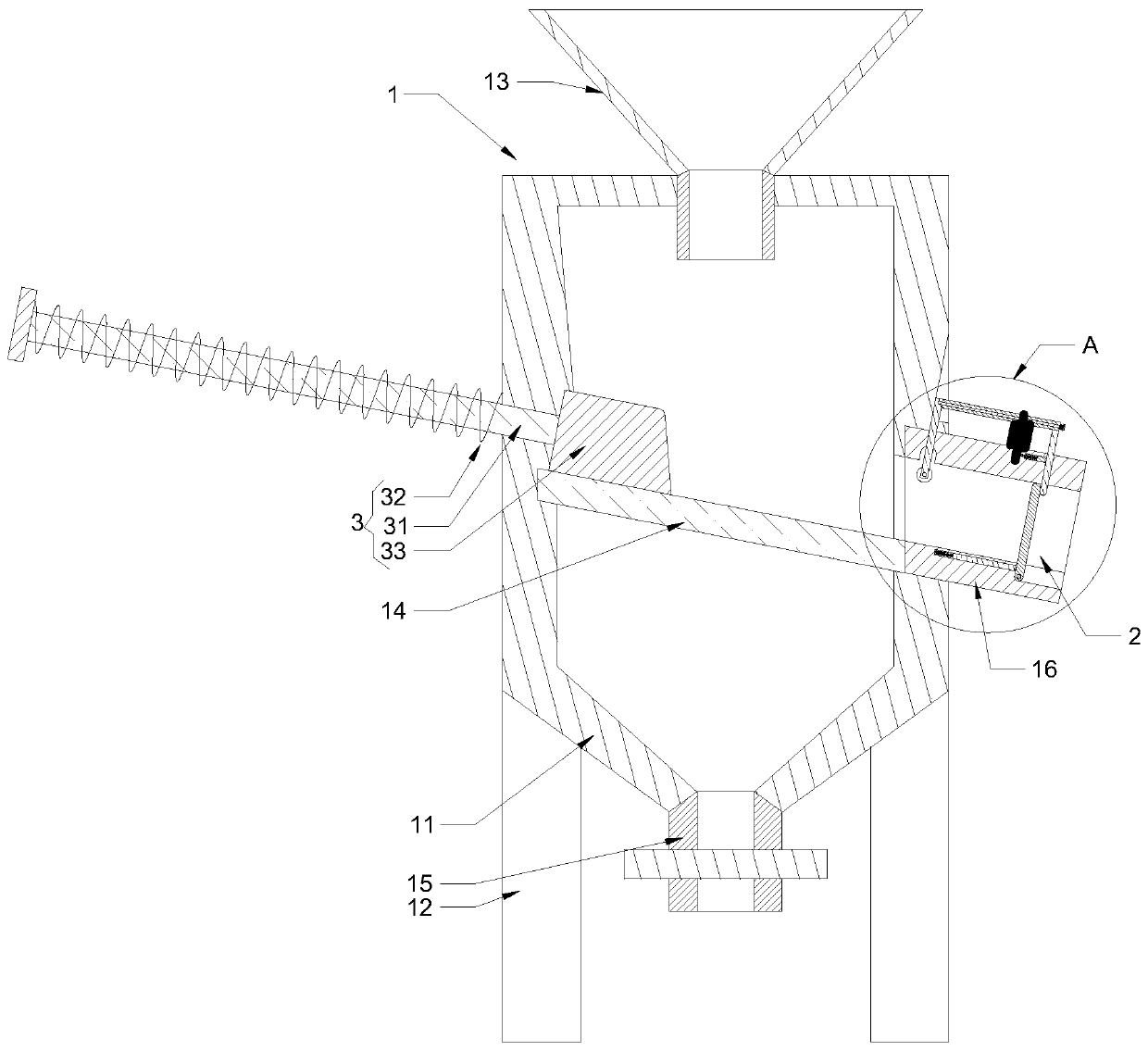

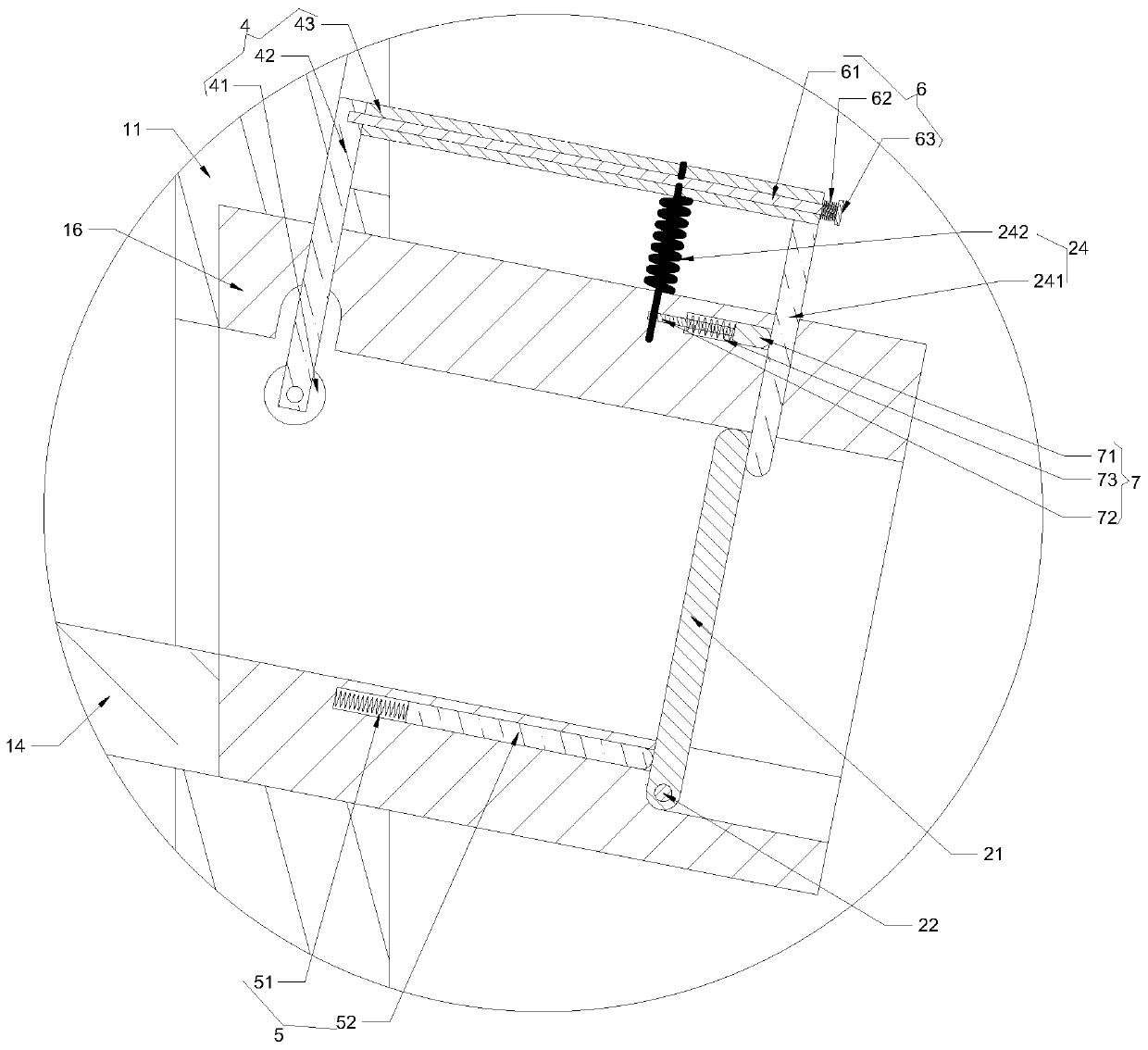

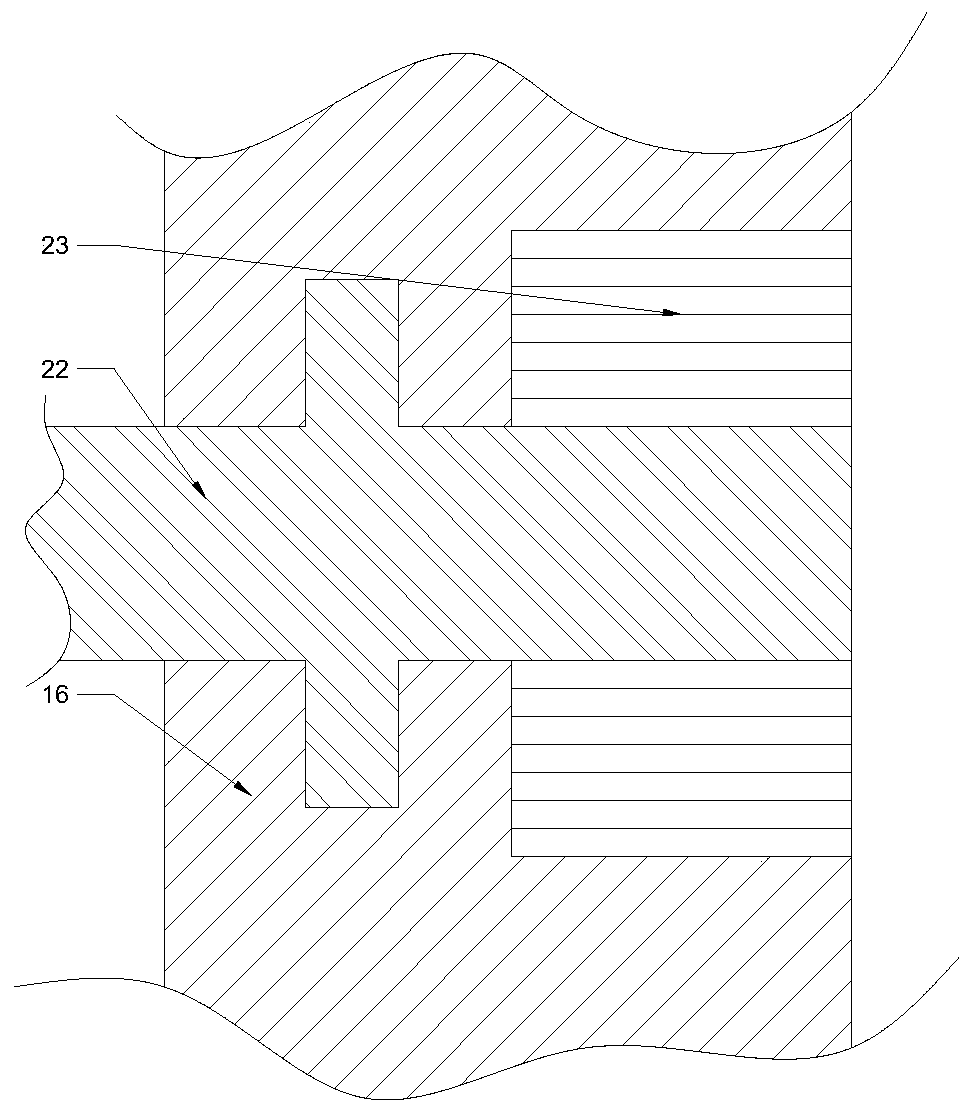

[0024] like Figure 1 to Figure 3 As shown, the present invention proposes a kind of coating raw material feeding bin, comprises: separation device 1, and it comprises: separation case 11, stand 12, hopper 13, filter screen 14 and first discharge pipe 15, separation case 11 passes vertical The frame 12 stands on the ground, and a cavity is provided in the separation box 11, and a filter screen 14 is installed on the cavity inwall, and the filter screen 14 divides the cavity into an upper cavity and a lower cavity, and the upper cavity is located above the lower cavity, and the filter screen 14 is arranged on the separation box. A hopper 13 communicating with the upper chamber is installed on the top o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com