Pigment treatment equipment for textile processing

A technology for processing equipment and pigments, applied in the processing of textile materials, equipment configuration for processing textile materials, textile processing machine accessories, etc., can solve the problems of poor dissolution effect, avoid energy waste, ensure effectiveness, and increase movement speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

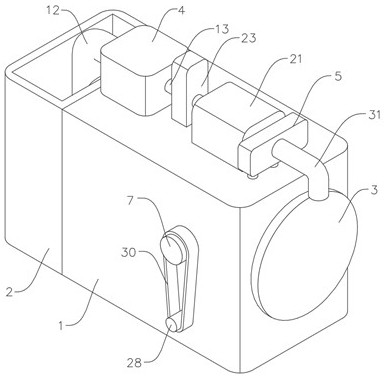

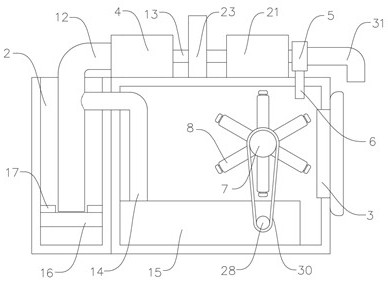

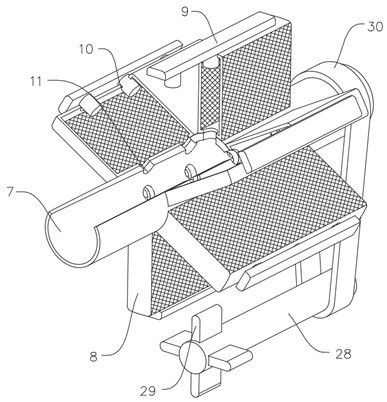

[0022] refer to Figure 1-3 , a kind of pigment processing equipment for textile processing, comprising a treatment box 1, a water tank 2 is fixed on the side wall of the treatment box 1, a door panel 3 is installed on the side wall of the treatment box 1, a pump box 4 is fixed on the top of the treatment box 1, the pump box The two sides of 4 are respectively inserted with a suction pipe 12 and a water delivery pipe 13, and the side wall of the water suction pipe 12 is inserted with a liquid suction pipe 14 communicating with the inside of the treatment tank 1. The water suction pipe 12 is located in the water tank 2, and the water suction pipe 12 The water flow inside the water tank 2 is extracted, and the liquid suction pipe 14 can extract the solution inside the treatment tank 1. The end of the water delivery pipe 13 is fixed with a distribution box 5, and the bottom of the distribution box 5 is inserted with a plurality of channels connected to the inside of the treatment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com