sand screening machine for construction machinery

A technology for construction machinery and sand screening machines, which is applied in screening, solid separation, cleaning methods and utensils, etc., can solve problems such as affecting screening efficiency, staying on screen plates, affecting sea sand screening, etc., so as to avoid sand accumulation, The effect of preventing screening efficiency and preventing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Such as Figure 1-Figure 5 Shown:

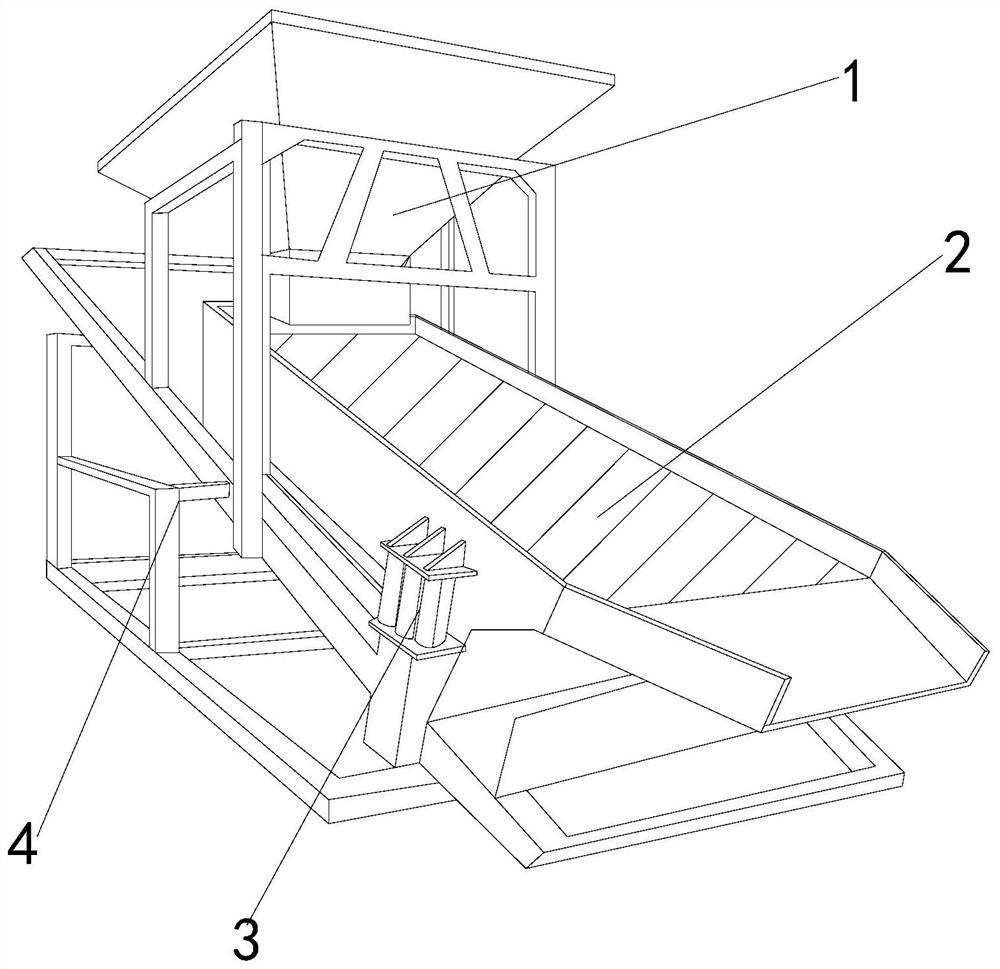

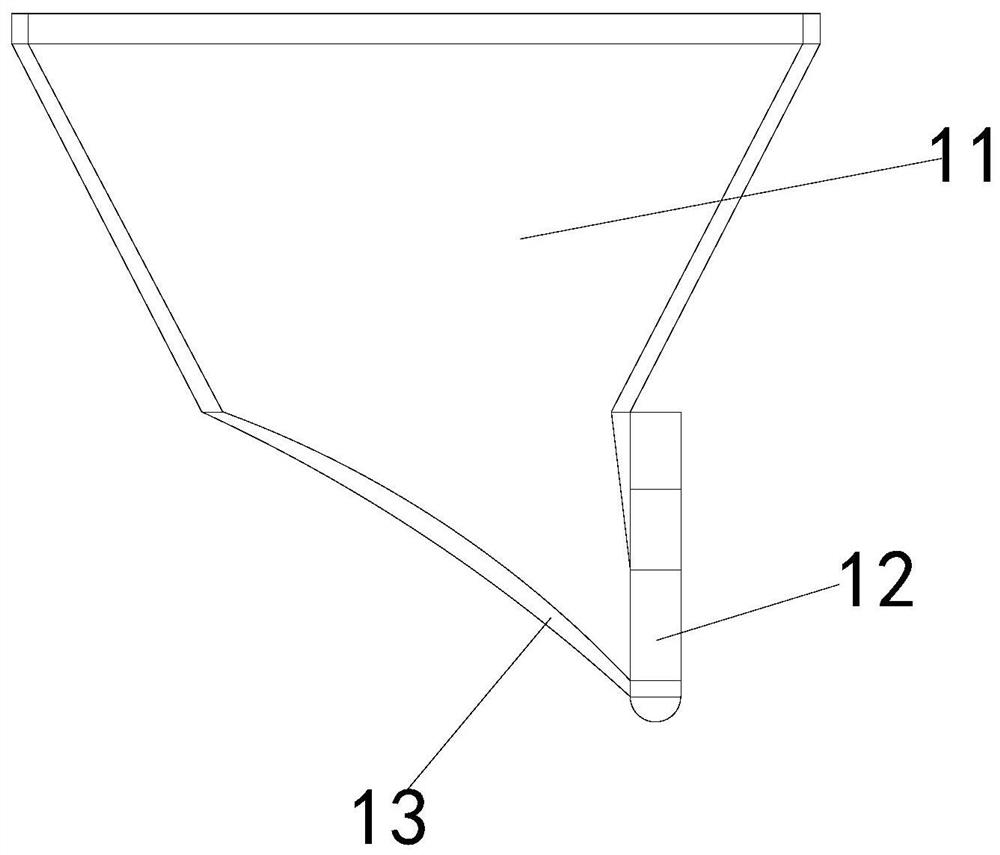

[0026] The present invention is a sand screening machine for construction machinery, a sand screening machine for construction machinery, its structure includes a feeding mechanism 1, a vibrating plate 2, a vibrator 3, and a support frame 4, and the feeding mechanism 1 is embedded and installed on the vibrating plate 2, the vibrator 3 is installed on the lower ends of both sides of the vibrating plate 2, the support frame 4 is welded on the lower end of the vibrating plate 2, the feeding mechanism 1 is provided with a feeding port 11, a fixed box 12, a bending Plate 13, the fixed box 12 is welded on the right side of the lower end of the feed port 11, the curved plate 13 is located on the left side of the fixed box 12, the outside of the feed port 11 is welded on the upper end of the vibrating plate 2, the The curved plate 13 is a smooth curved structure, and its right end is embedded in the left end of the fixed box 12 to increase t...

Embodiment 2

[0033] Such as Figure 6-Figure 8 Shown:

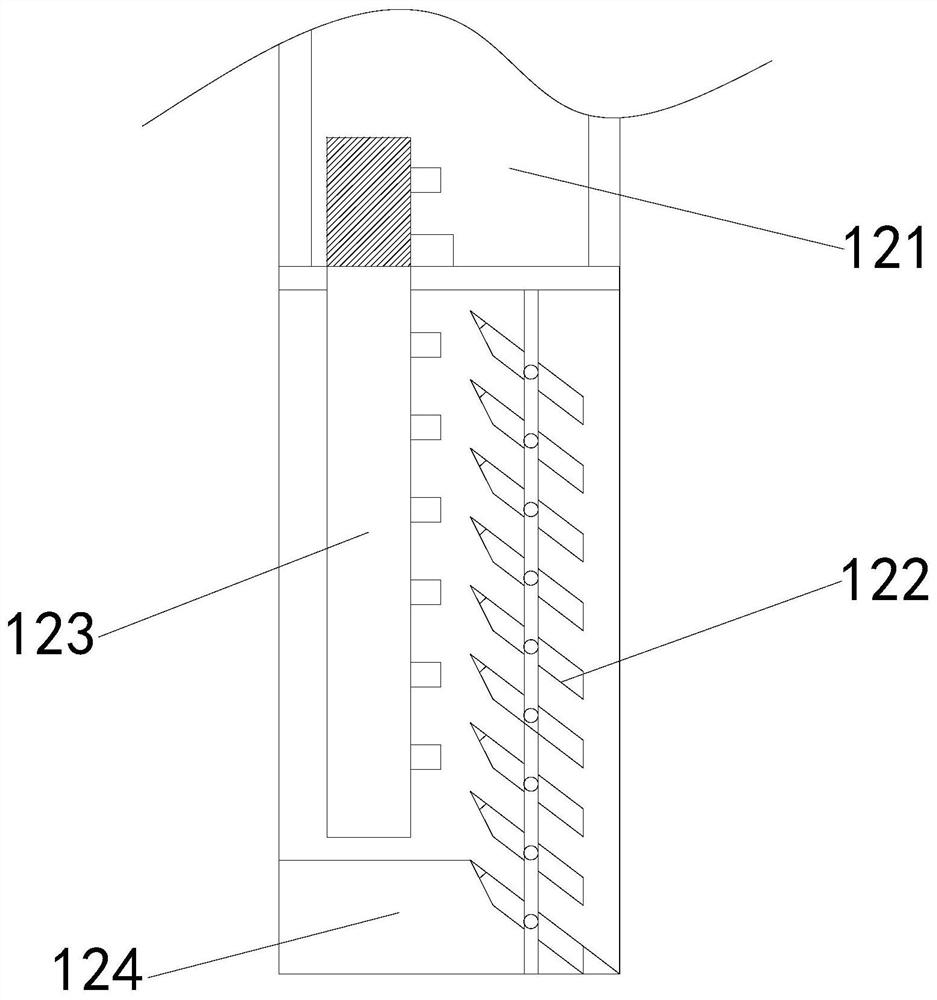

[0034] Wherein, the cleaning mechanism 123 is provided with a cleaner w1, a filter mechanism w2, a rotating tank w3, and a discharge port w4, the filter device w2 is located outside the rotating tank w3, and the cleaner w1 is located at the upper end of the discharge port w4 , the cleaner w1 is installed on the lower surface of the storage tank 121, the rotating groove w3 and the discharge port w4 are parallel to each other, and the inner side of the filtering mechanism w2 is screwed with the rotating groove w3 to prevent the filtering mechanism w2 from rotating. Change its horizontal angle to avoid the cleared crabs from slipping off the filter mechanism w2.

[0035] Wherein, the cleaner w1 is provided with an inclined plate w11 and a cleaning block w12, the cleaning block w12 is embedded and fixed on the outer end of the inclined plate w11, the cleaning block w12 is in clearance fit with the filter mechanism w2, and the inclined pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com