Lining defect removal device of cast iron pipe

A cleaning device, a technology for cast iron pipes, applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problem that the cleaning quality of cast iron pipe linings cannot be effectively guaranteed, the cleaning efficiency of cast iron pipes is difficult to guarantee, and the cleaning efficiency Low-level problems, to achieve the effect of eliminating manual cleaning, saving manpower and ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

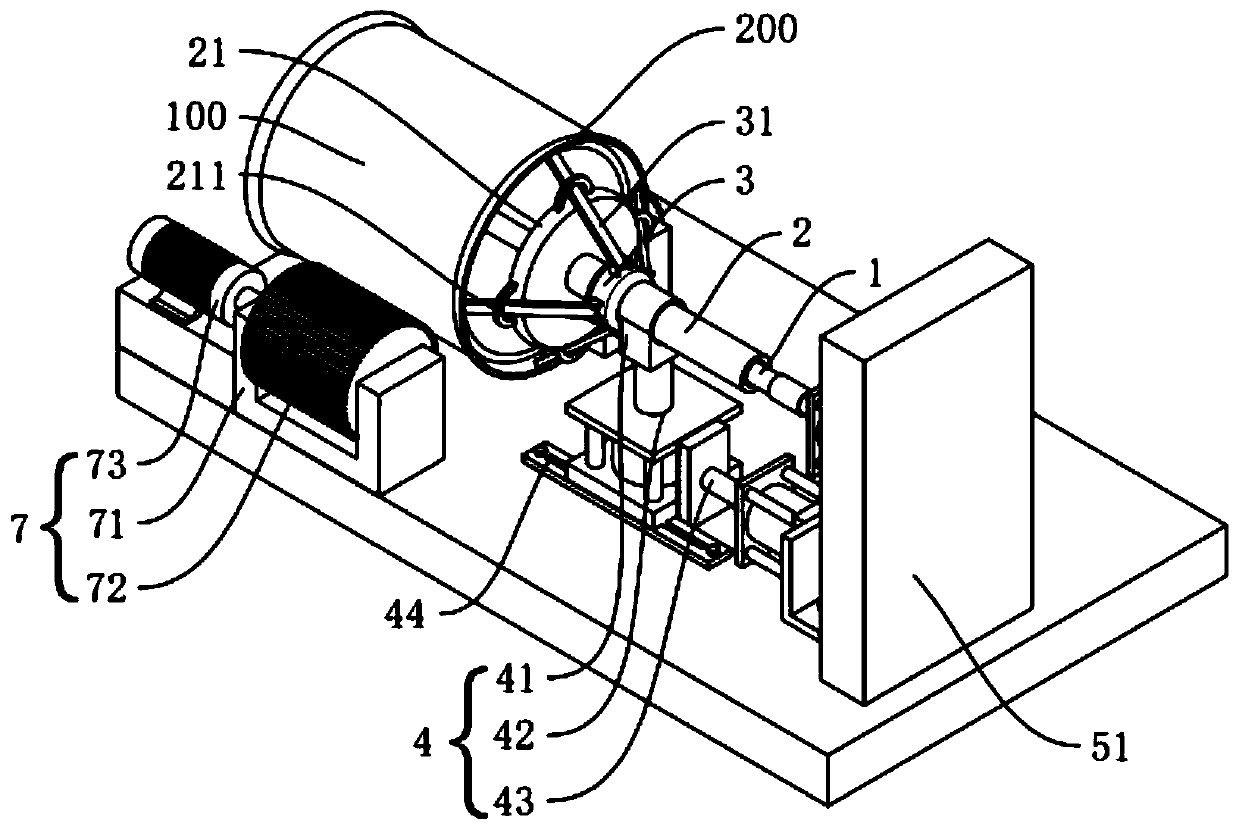

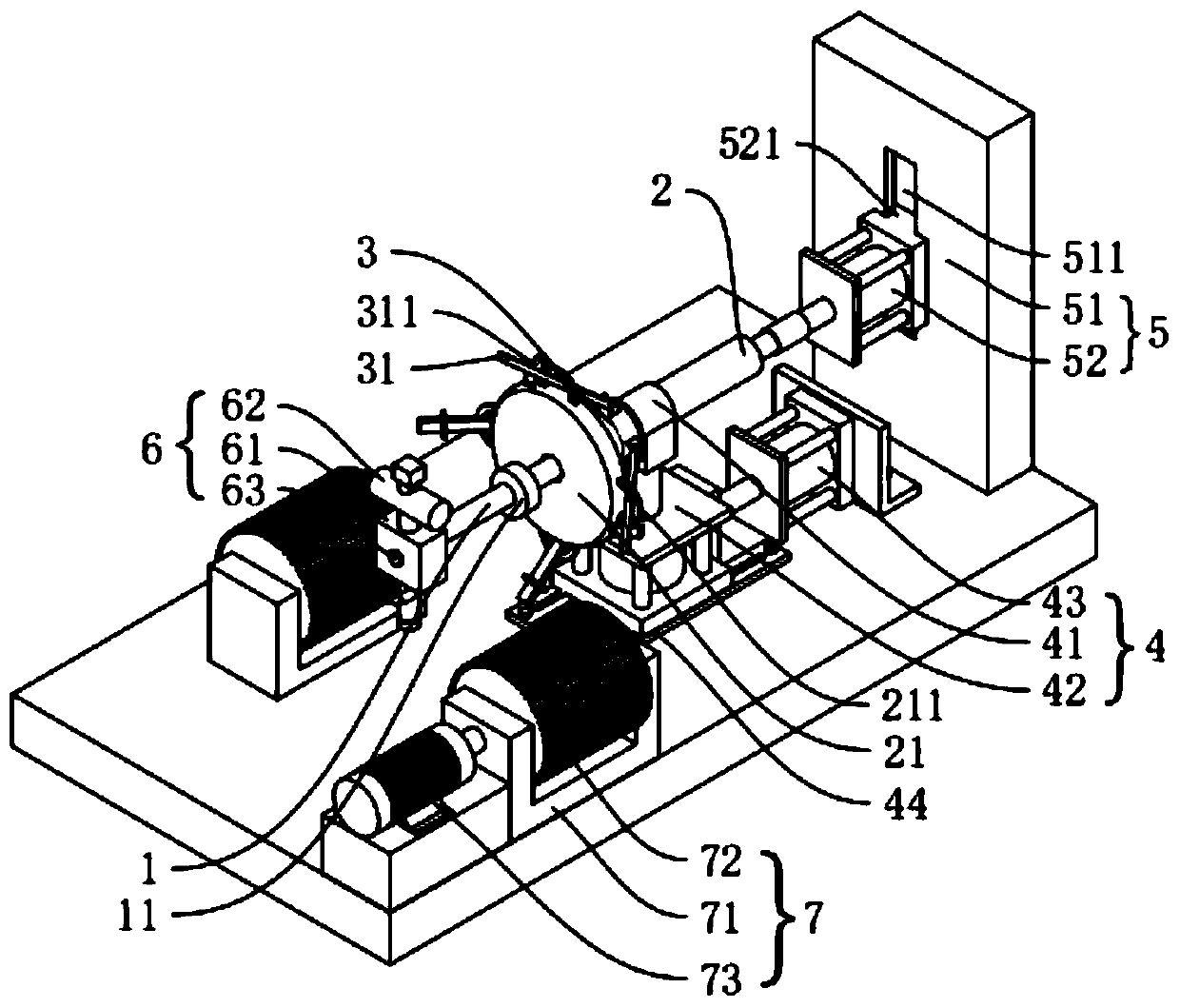

[0079] Please refer to figure 1 with figure 2 As a specific implementation of a cast iron pipe liner defect cleaning device provided by the present invention, the supporting drive assembly 7 includes two roller seats 71, two drive rollers 72 and a rotating motor 73

[0080] The two roller seats 71 are used to be fixed on the ground, and the two roller seats 71 are arranged oppositely; the two driving rollers 72 correspond to the two roller seats 71 one-to-one, and the driving rollers 72 are rotatably arranged on the roller seats 71. The driving roller 72 is used to support both sides of the tube body 100 respectively.

[0081] The rotating motor 73 is connected with one of the driving rollers 72 to drive the driving roller 72 to rotate along its circumference; specifically, the fixed end is fixed on the ground or the roller base 71, and the power driving end penetrates the roller base 71 and is connected to the driving roller 72 connection.

[0082] By adopting the above technical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com