A block-detachable annular working platform and its construction method

A work platform, disassembly-type technology, applied in the direction of construction, scaffolding accessories, building structure support, etc., can solve the problem of not being able to use lifting equipment to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific examples.

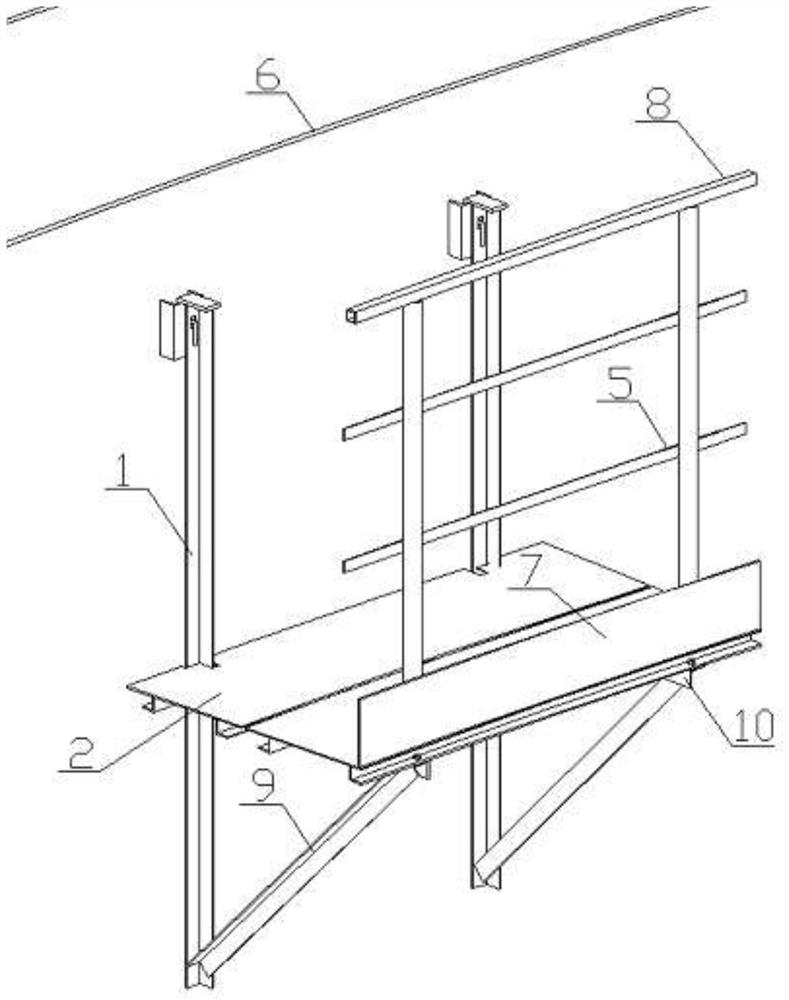

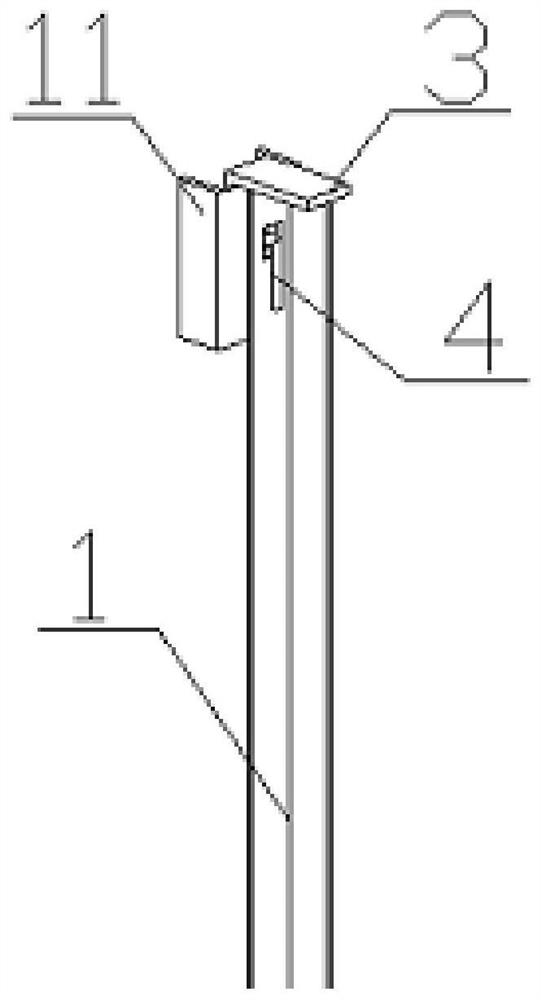

[0023] A block-detachable annular working platform, comprising at least two triangular supports, the triangular supports are composed of support structure vertical rods 1, inclined support rods 9, and horizontal angle steel 10, and the detachable platform 2 is installed on the triangular supports. The front end of the detachable platform is connected with each support structure pole 1 through a card slot, and the inclined support rod 9 is installed on the lower part of the detachable platform 2, and the detachable platform 2 is supported on the support structure pole 1, The horizontal angle steel 10 fixes the position of the detachable platform 2; a hook 3 is installed on the front side of the top of the support structure pole 1, and a backstop device 4 is arranged on the support structure pole 1 where the hook 3 is installed; the support structure vertical A channel steel 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com