Concrete crack repairing device and method

A crack repair and concrete technology, applied in building maintenance, construction, building structure, etc., can solve the problems of poor filling effect, difficult to ensure the completeness of crack filling, etc., and achieve the effects of small damage, quick repair and various functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings.

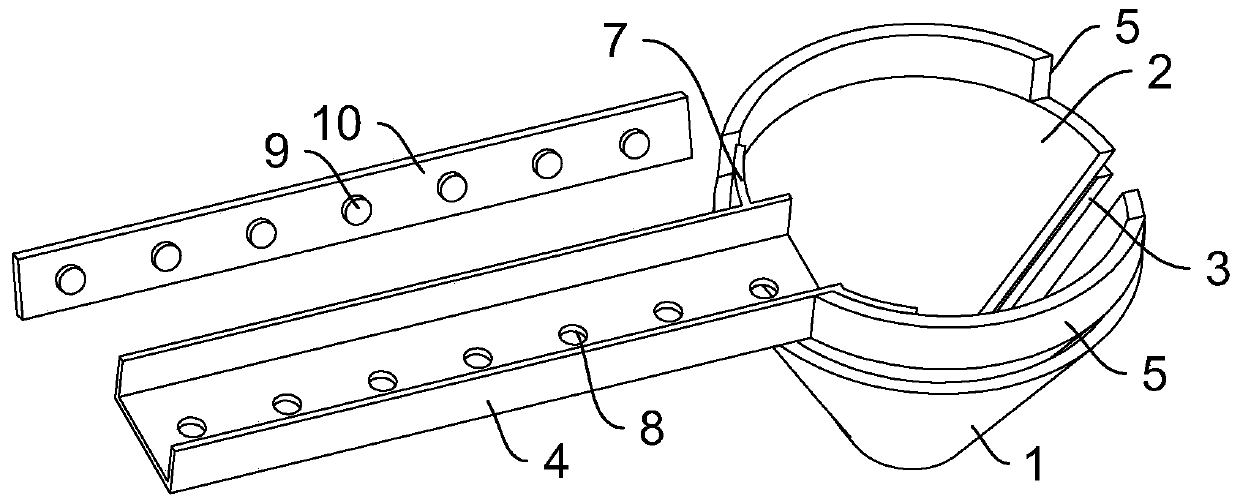

[0046] refer tofigure 1 , is a concrete crack repairing device disclosed by the present invention, comprising a plurality of concrete prefabricated pipes 1 driven into the crack, the plurality of concrete prefabricated pipes 1 are respectively arranged in sequence along the extension direction of the crack, and also includes a plurality of The grout hopper 2 in the prefabricated pipe 1, the outer wall of the grout hopper 2 is fitted to the inner wall of the concrete prefabricated pipe 1, the concrete prefabricated pipe 1 and the grout hopper 2 are arranged in a funnel shape, the grout hopper 2 and the concrete prefabricated pipe Two slurry guide grooves 3 are arranged symmetrically on one side. The grout is poured into the cracks by using the grout hopper 2 and the prefabricated concrete pipe 1 together, and the prefabricated concrete pipe 1 and the prefabric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com