A self-cleaning stopper for underground garage

An underground garage and limiter technology, which is applied to building types, buildings where cars are parked, buildings, etc., can solve problems such as serious friction between warning tubes and wheels, and reflective signs are easily polluted.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

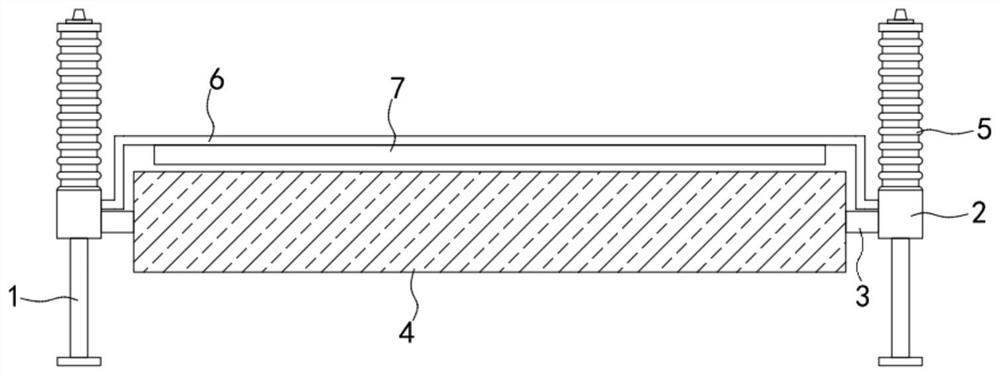

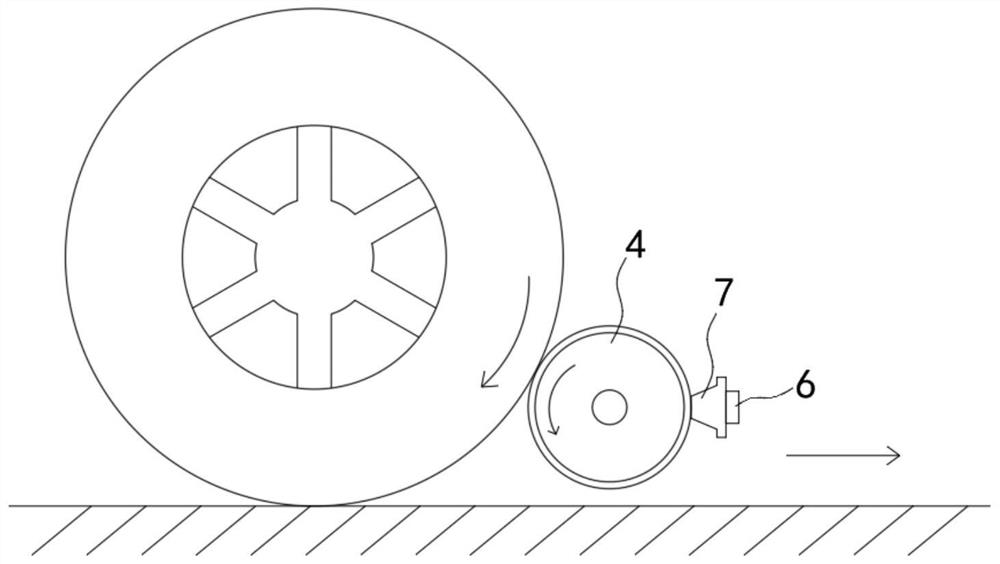

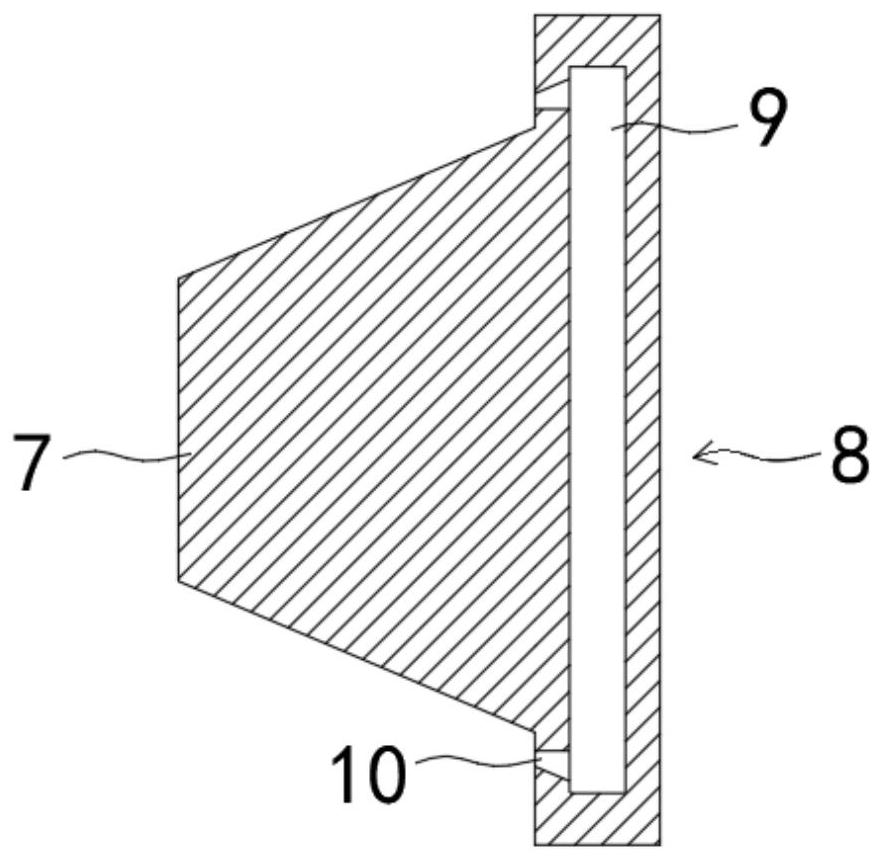

[0027] Such as Figure 1-3 As shown, a self-cleaning underground garage limiter includes two slide bars 1, which are installed side by side and horizontally on the ground, and the direction of the slide bars 1 is consistent with the driving direction of the car; 2 is slidably connected to the slider 1. Specifically, the slider 2 can be made of rubber material, which can improve the wear resistance of the slider 2, and at the same time can improve the air tightness between the slider 2 and the slider 1, reducing impurities or Dust enters the gap between the slider 2 and the slider 1 to ensure that the slider 2 slides well; the fixed shaft 3 is fixedly connected between the two sliders 2, and the fixed shaft 3 is vertical to the slider 1 , that is, the fixed shaft 3 is perpendicular to the driving direction of the vehicle; the warning tube 4 is sleeved on the fixed shaft 3 in rotation, and the surface of the warning tube 4 is provided with a warning sign, which can be painted wi...

Embodiment 2

[0035] Such as Figure 4-5 As shown, the difference between this embodiment and Embodiment 1 is that: the sliding rod 1 is also covered with a reinforced corrugated sleeve 11, and the reinforced corrugated sleeve 11 can adopt the same structure as the elastic corrugated sleeve 5, that is, the materials and functions of the two The functions are the same, the reinforced corrugated sleeve 11 and the elastic corrugated sleeve 5 are installed on both sides of the slider 2 one after the other, the reinforced corrugated sleeve 11 and the elastic corrugated sleeve 5 communicate with the connecting pipe 6 through the integration mechanism 12 at the same time, and the integration mechanism 12 It includes a main pipe 13 communicated with the connecting pipe 6, and two branch pipes 14 for one-way air intake are communicated with the main pipe 13, and the two branch pipes 14 communicate with the reinforced bellows sleeve 11 and the elastic bellows sleeve 5 respectively.

[0036]By setting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com