Forklift lithium battery pack

A lithium battery pack and lithium battery technology, applied in the field of forklifts, can solve the problems of poor heat dissipation, inconvenient disassembly and installation, inability to prevent multiple lithium batteries from shaking and damage, etc., to improve heat dissipation, long service life, and waterproof effect. long lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

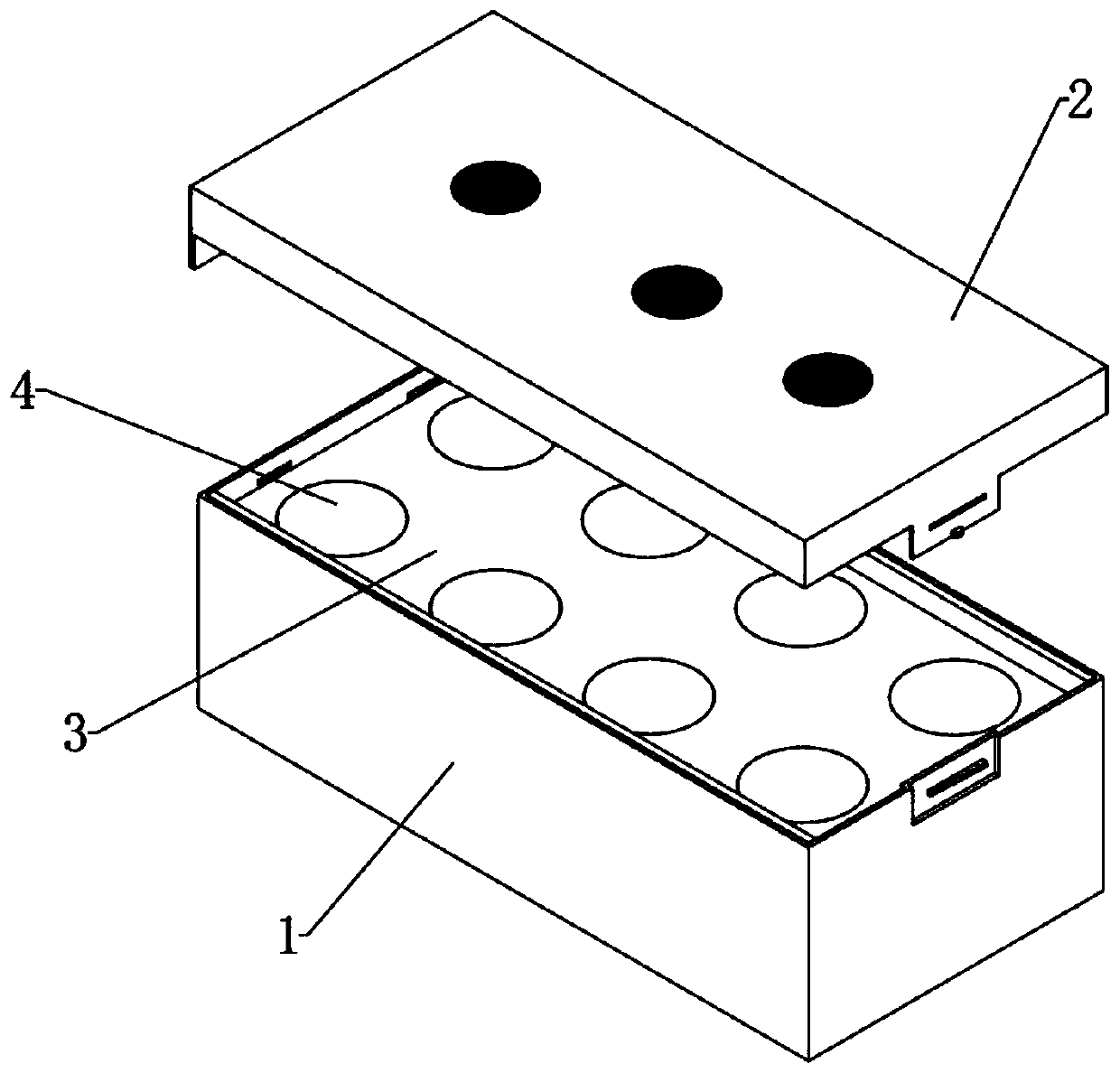

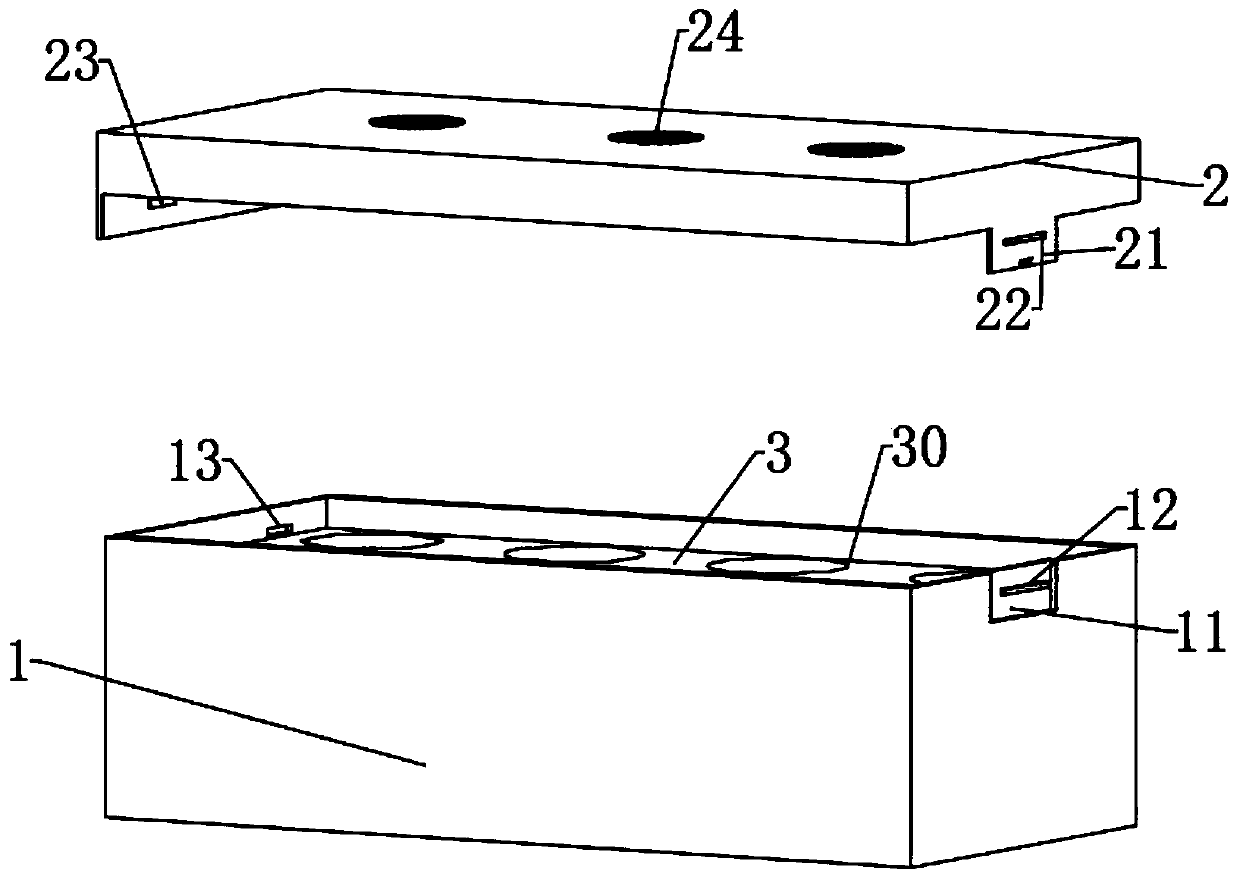

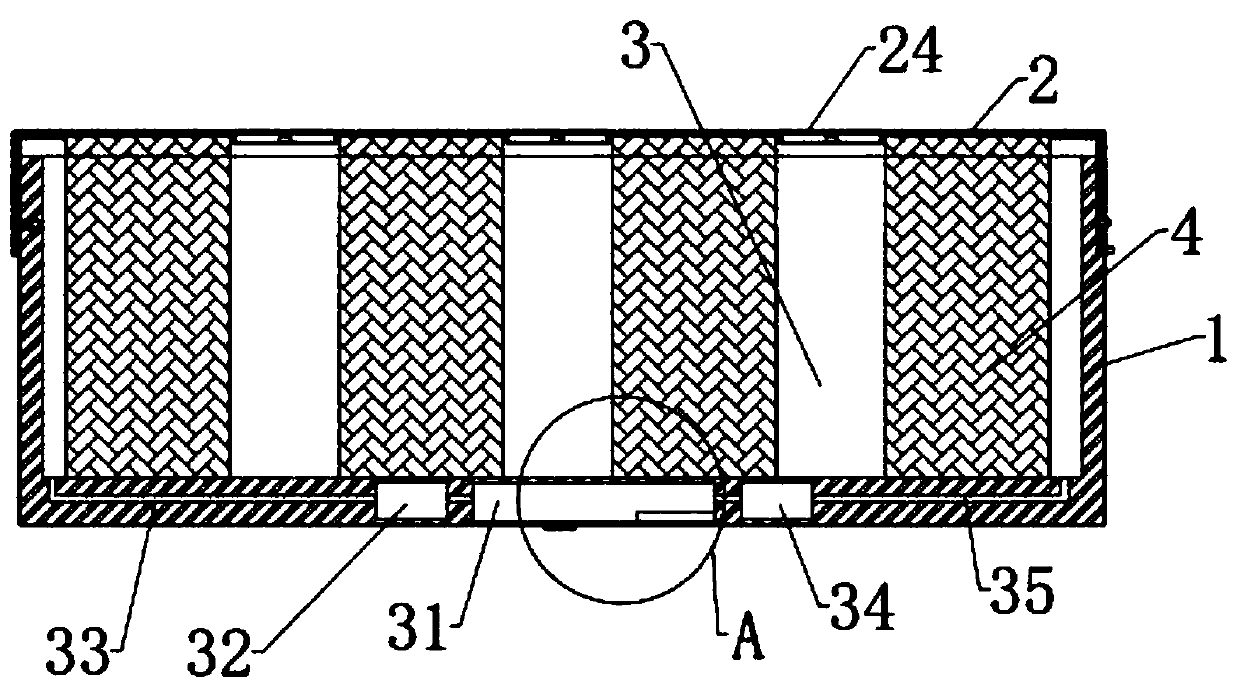

[0029] A forklift lithium battery pack, in order to solve the problems of inconvenient disassembly and installation of ordinary lithium battery packs, poor heat dissipation effect, and inability to prevent shaking damage between multiple lithium batteries, as a preferred embodiment, such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the casing 1 is included. The top of the casing 1 is sealed and clamped with an upper cover 2, and the top of the upper cover 2 is embedded with a cooling fan 24, which can dissipate the inner cavity. The cooling fan 24 is a YRD type cooling fan .

[0030] Specifically, the outer side wall of the housing 1 is provided with a limiting slot 11, the inner cavity of the limiting slot 11 is provided with a limiting block 12, the bottom of the upper cover 2 is provided with a limiting plate 21, the limiting plate 21 is provided with a fixing slot 22, and a limiting plate 21 It is matched with the limiting slot 11, and the fixing slot 22 is sna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com