Application of organosilicon compounds in the preparation of negative electrode materials for lithium-ion batteries

A lithium-ion battery and compound technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve problems such as battery cycle performance degradation, battery life reduction, active material shedding, etc., to eliminate difficult problems, volume The effect of small effect and low volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

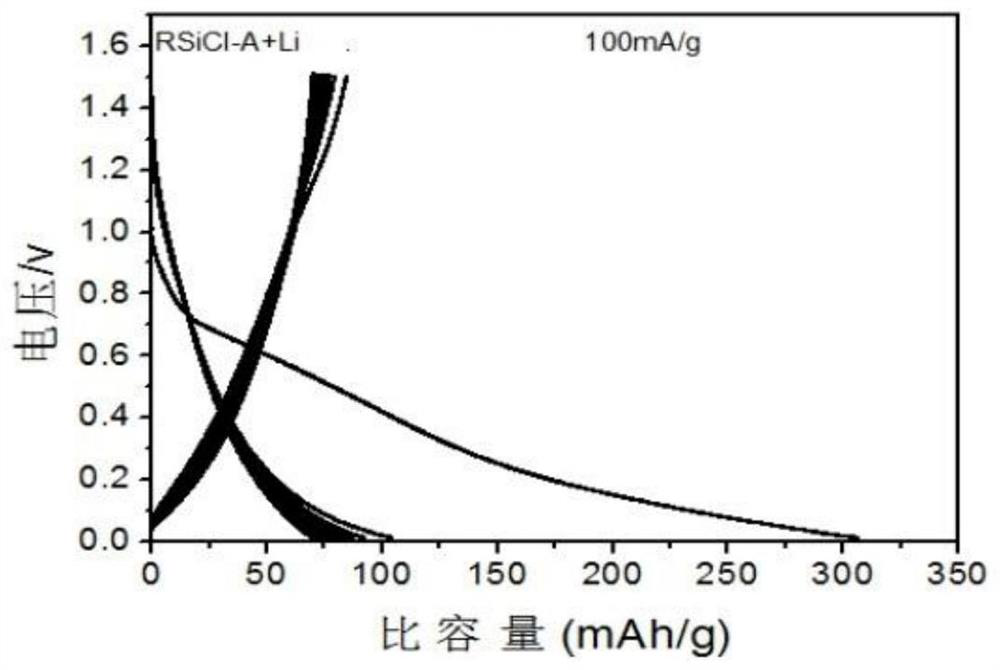

[0037] The organosilicon compound (referred to as organosilicon compound 1) shown in the structure of formula (1) is applied to the steps of preparing lithium-ion battery negative electrode:

[0038] 1) Preparation of the negative electrode sheet: In an argon-protected glove box, the organosilicon compound 1, conductive carbon black, and polyvinylidene fluoride were mixed and ground into powder according to the mass ratio of 7:2:1, and dispersed in the solvent N- In methylpyrrolidone, ultrasonication for 1 hour and stirring for 3 hours at room temperature to make the powder evenly mixed in the solvent to make a slurry, apply the slurry evenly on the cleaned metal Cu sheet, turn it out of the glove box, and put it away quickly Put it in a vacuum oven at 120°C for 24 hours. Compact the dried negative electrode sheet with 10MPa on a tablet press, quickly transfer it to the glove box, and cut the negative electrode sheet into small discs with a diameter of 16mm with cutting pliers...

Embodiment 2

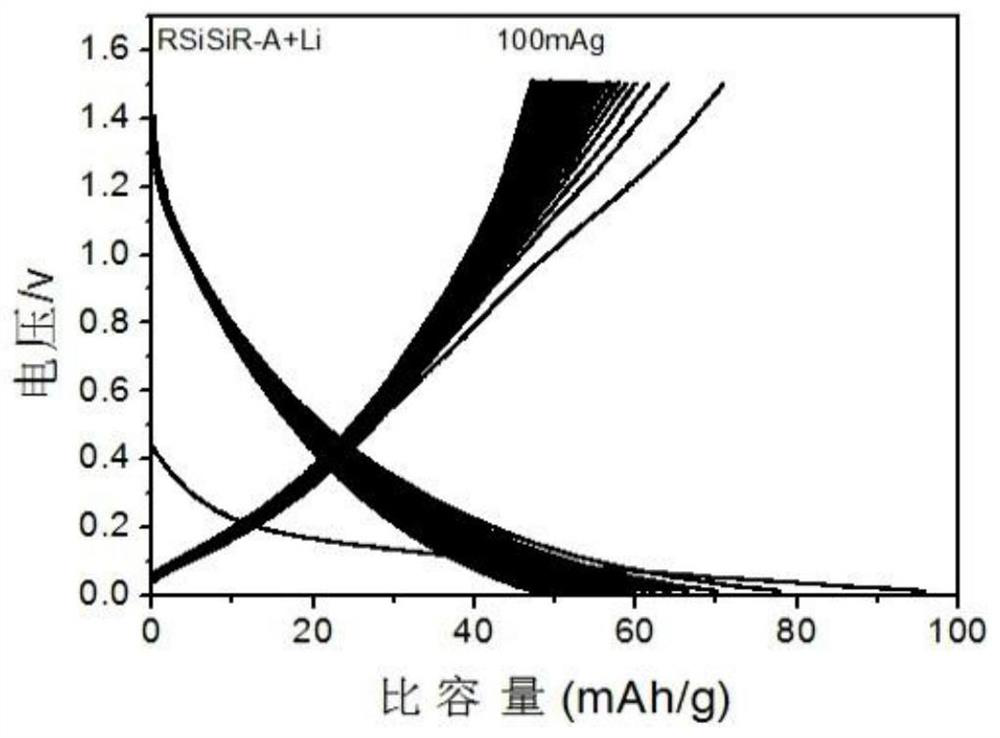

[0042] The organosilicon compound (referred to as organosilicon compound 2) shown in the structure of formula (2) is applied to the steps of lithium-ion battery negative electrode:

[0043] 1) Preparation of the negative electrode sheet: In an argon-protected glove box, mix and grind organosilicon compound 2, conductive carbon black, and polyvinylidene fluoride into powder according to a mass ratio of 7:2:1, and use N-formazol Based on pyrrolidone as solvent, ultrasonic for 1 hour and stirred for 3 hours at room temperature, the powder is mixed evenly in the solvent to make a slurry, and the slurry is evenly coated on a clean metal Cu sheet, transferred out of the glove box, and the sample is quickly Put it into a vacuum drying oven at 120° C. for 24 hours. Compact the dried negative electrode sheet with 10MPa on a tablet press, quickly transfer it to the glove box, and cut the negative electrode sheet into small discs with a diameter of 16mm with cutting pliers to obtain a lo...

Embodiment 3

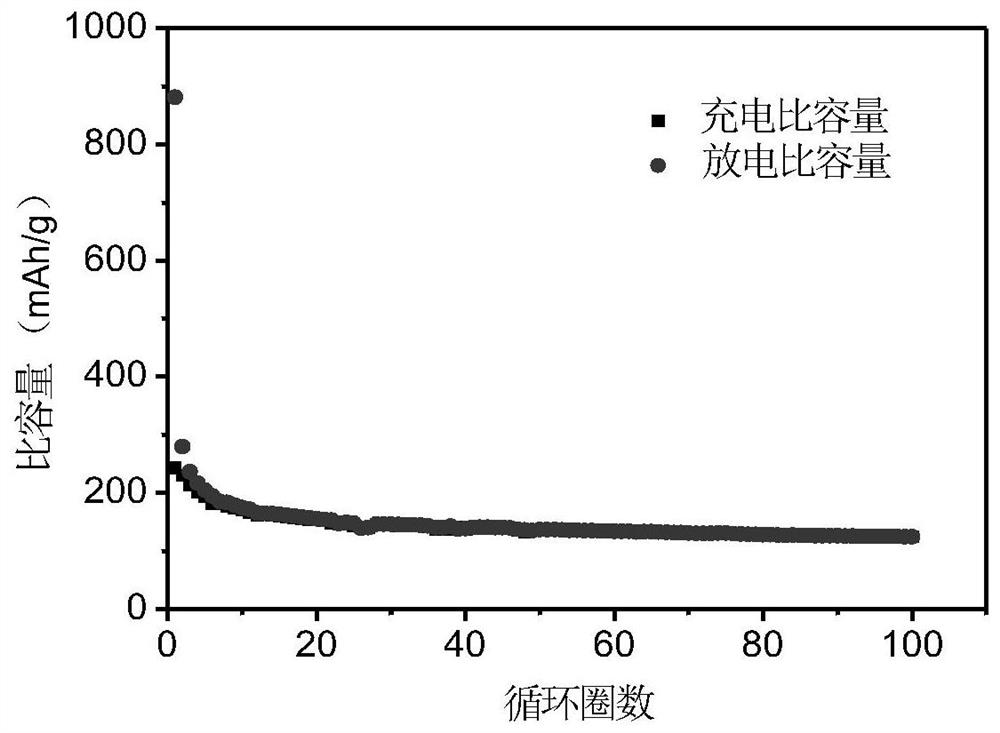

[0047] The organosilicon compound (referred to as organosilicon compound 3) shown in the structure of formula (3) is applied to the steps of lithium-ion battery negative electrode:

[0048] 1) Preparation of the negative electrode sheet: Mix and grind organosilicon compound 3, conductive carbon black, and polyvinylidene fluoride into powder according to the mass ratio of 7:2:1, disperse them in the solvent N-methylpyrrolidone, and ultrasonicate at room temperature for 1 hours, and stirred for 3 hours, the powder was uniformly mixed in the solvent to make a slurry, and the slurry was evenly coated on the cleaned metal Cu sheet, transferred out of the glove box, and kept in a vacuum oven at 120°C for 24 hours. Compact the dried negative electrode sheet with 10MPa on a tablet press, quickly transfer it to the glove box, and cut the negative electrode sheet into small discs with a diameter of 16mm with cutting pliers to obtain a loading capacity of 1-2 mg / cm 2 of the negative elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap