An adsorption-enhanced filter material

An enhanced filter material technology, which is applied in the direction of filtration separation, fiber type, textile material treatment, etc., can solve the problems of poor adsorption effect of filter materials, and achieve the effect of improving processing efficiency, improving filterability, and good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

[0032] Embodiments of the invention are:

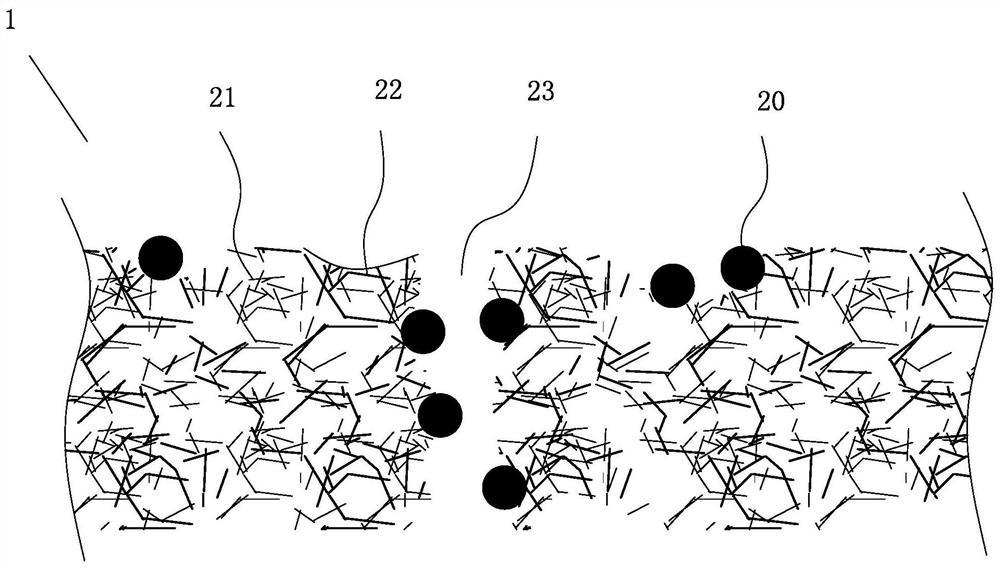

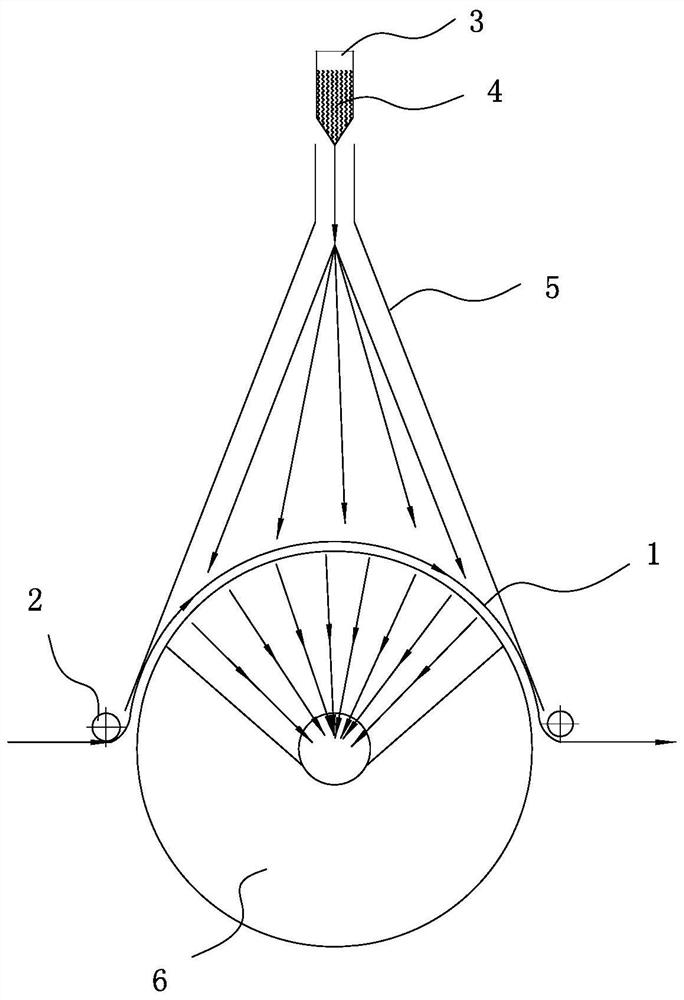

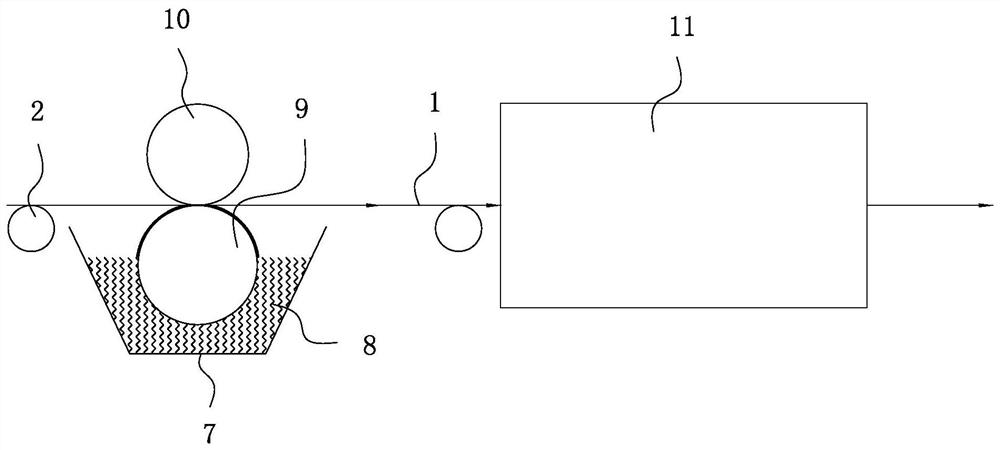

[0033] refer to figure 1 As shown, an adsorption-enhanced filter material includes a filter material body 1, and the filter material body 1 includes a first fiber filament material and a second fiber filament material divided by high melt index polypropylene resin, which are respectively connected through two melt-blown molds The first fiber filaments 21 and the second fiber filaments 22 with different diameters are formed by spraying, the first fiber filaments 21 and the second fiber filaments 22 are randomly arranged to form a fiber network structure, and then mechanically, thermally bonded or chemically reinforced, preferably The use of chemical methods enables the subsequent formation of a non-woven fabric with a rough surface, the grooves of which can maintain the original structure, and the space form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com