Chinese bacon slicing device capable of achieving automatic loading and unloading

An automatic loading and unloading device technology, applied in metal processing and other directions, can solve problems such as high cost, delay of subsequent processes, and sticking of meat slices together

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

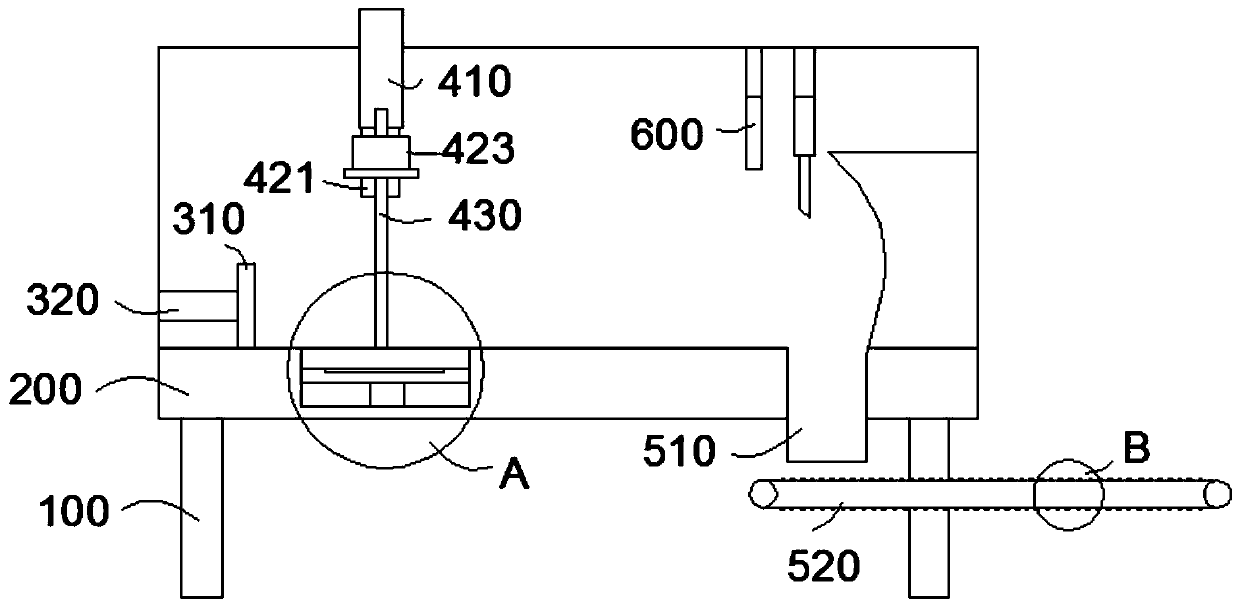

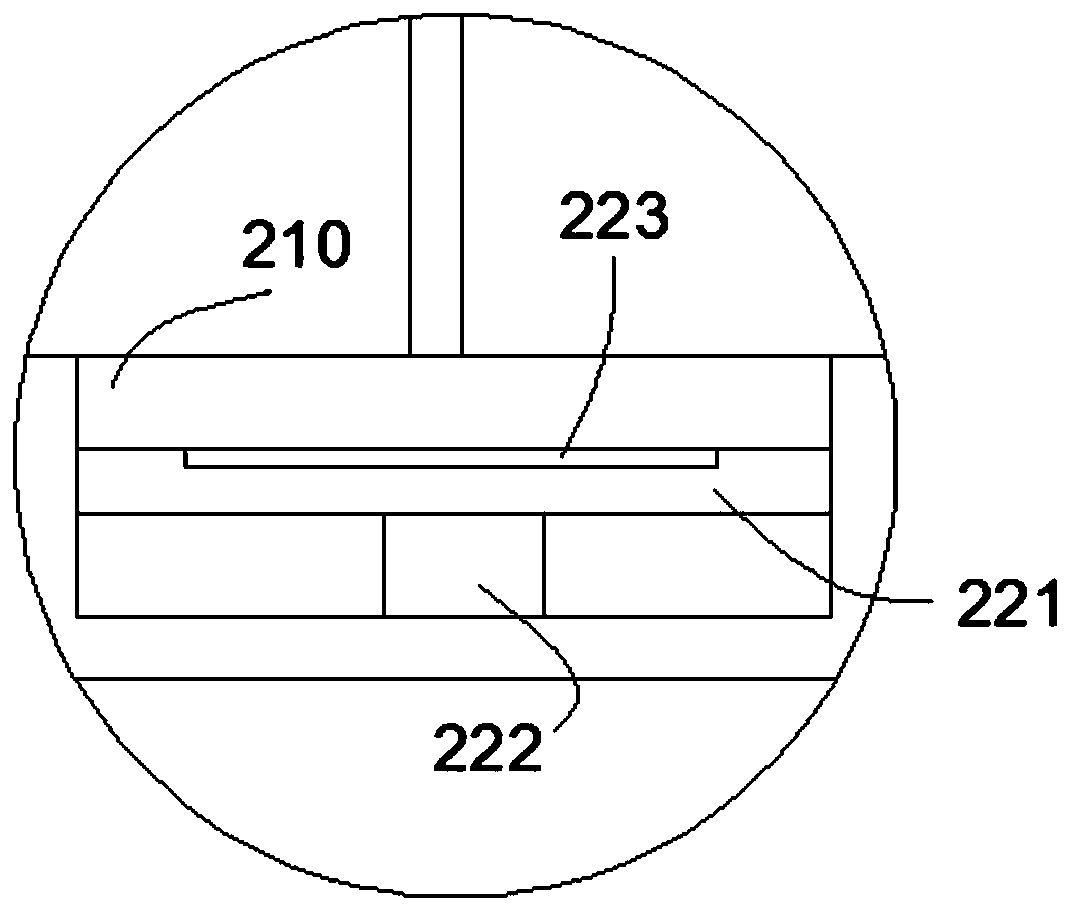

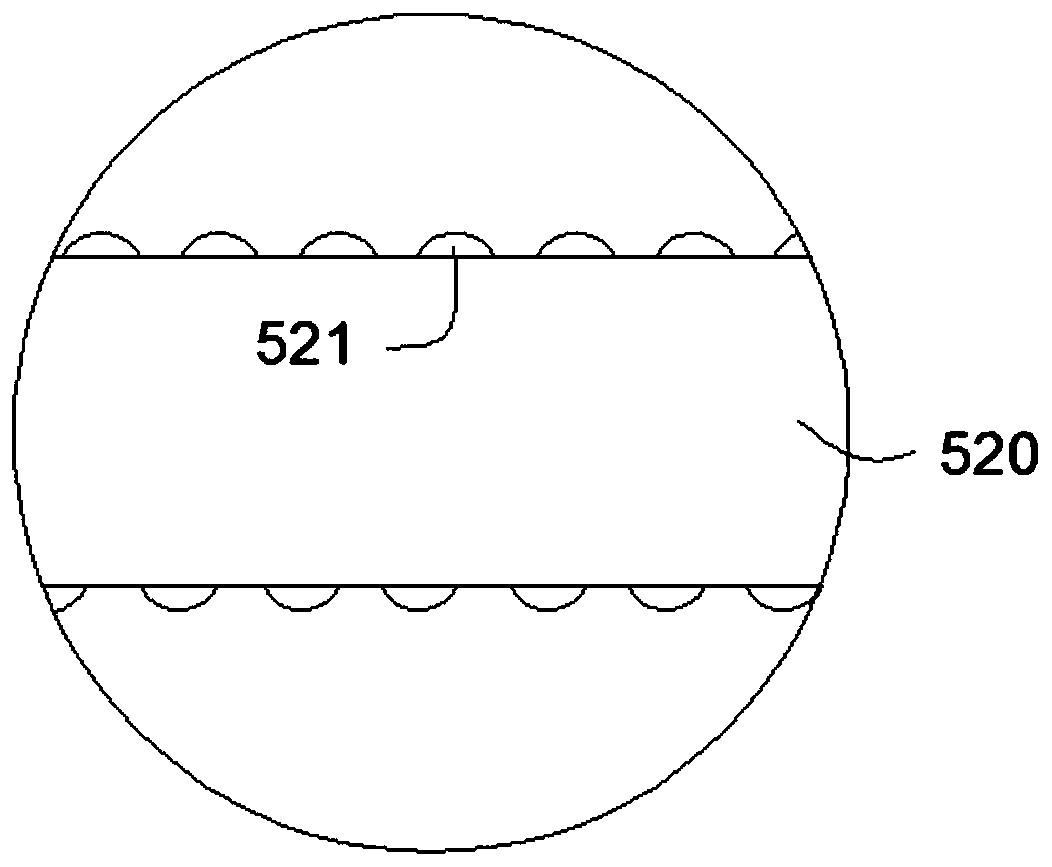

[0026] Such as Figure 1 to Figure 5 As shown, the invention discloses a bacon cutting device with automatic loading and unloading. Specifically, the device includes a casing, which can protect workers from injury and prevent foreign impurities from entering the device and causing pollution. A slicing machine is arranged in the casing, and the slicing machine includes a pushing device and a slicing device. Such as figure 1 As shown, the slicing machine includes a frame 100 and a feeding platform 200 arranged on the upper surface of the frame 100. One end of the feeding platform 200 is equipped with a pushing device, and the upper side of the pushing device is equipped with a feeding device. The feeding platform of the slicing machine The other end of 200 is equipped with a slicing device, and a discharge device is arranged below the slicing device.

[0027] Such as figure 1 with Figure 5 As shown, the feeding device includes a feeding channel 410, a feeding part communic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com