Highly adaptable ballastless track track slab crack and automatic detection device

An automatic detection device, ballastless track technology, applied in the field of track slab crack and separation detection, can solve the problems of small audience, track slab rupture, lack of automatic detection technology and equipment, etc., to achieve the effect of strengthening market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

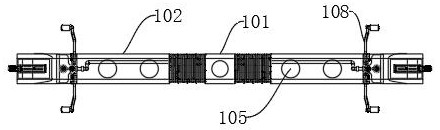

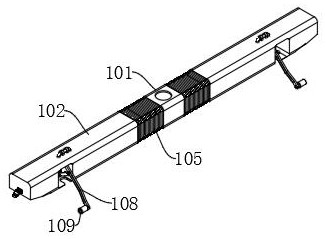

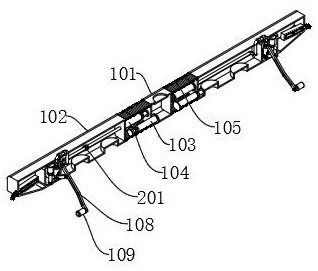

[0029] refer to Figure 1-8 , with highly adaptable ballastless track track slab cracks and automatic detection device, including: the central hydraulic drive assembly 101, the outer support frame 102, the connecting hydraulic rod 103 and the linkage hydraulic rod 104, the upper side of the central hydraulic drive assembly 101 is set There is a groove connected with the external push rod, and a group of connecting hydraulic rods 103 and a group of linkage hydraulic rods 104 are fixedly installed on the left and right sides of the middle hydraulic drive assembly 101, and the connecting hydraulic rods 103 and the linkage hydraulic rods 104 are connected to the outer support frame 102 respectively. The inner end is fixedly connected, the left and right edges of the middle hydraulic drive assembly 101 are fixedly connected to the inner side of the corrugated rubber connecting ring 105, and the outer side of the corrugated rubber connecting ring 105 is fixedly connected to the inner...

Embodiment 2

[0032] Embodiment 2: the difference based on Embodiment 1 is;

[0033] The front end of the connecting hydraulic rod 103 is fixedly connected to the outer support frame 102, the tail ends of the connecting hydraulic rod 103 on both sides are respectively fixedly connected to the left and right sides of the middle hydraulic drive assembly 101, and the tail end of the linkage hydraulic rod 104 is fixedly connected to the outer support frame 102. The front end of the linkage hydraulic rod 104 on the side is fixedly connected to the left and right sides of the middle hydraulic drive assembly 101 respectively, the tail end of the linkage hydraulic rod 104 is fixedly connected to the tail end of the balance hydraulic rod 106 through a pipe, and the balance hydraulic rod 106 is fixedly installed in the middle of the outer support frame 102 In the outer position, the lower end of the balance hydraulic rod 106 is fixedly connected to the upper side of the fine-tuning mechanism, and a gr...

Embodiment 3

[0037] Embodiment 3: the difference based on embodiment 1 is;

[0038] The safety lock mechanism includes: self-locking bolt and self-locking screw sleeve, and self-locking bolt includes: bolt housing 401, rotating rod 402, rotating shaft 403, limit spring 404, limit groove 405 and limit rod 406, and mobile platform 305 is away from A bolt housing 401 is fixedly installed on the upper surface of one side, and a rotating shaft 403 is fixedly installed in the middle of the bolt housing 401. The rotating shaft 403 is movably connected with the middle part of the rotating rod 402, and the rear side of the lower end of the rotating rod 402 is fixedly connected with the front side of the limit spring 404. , the rear side of the limit spring 404 is fixedly connected with the inner wall of the bolt housing 401, the upper side of the rotation rod 402 is provided with a limit groove 405, the inside of the limit groove 405 is provided with a limit rod 406, and the left and right sides of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com