Channel structure of a waste battery recycling device

A technology of waste batteries and recycling devices, applied in garbage collection, household appliances, trash cans, etc., can solve problems such as pollution, toxicity, and environmental pollution, and achieve the effect of avoiding sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

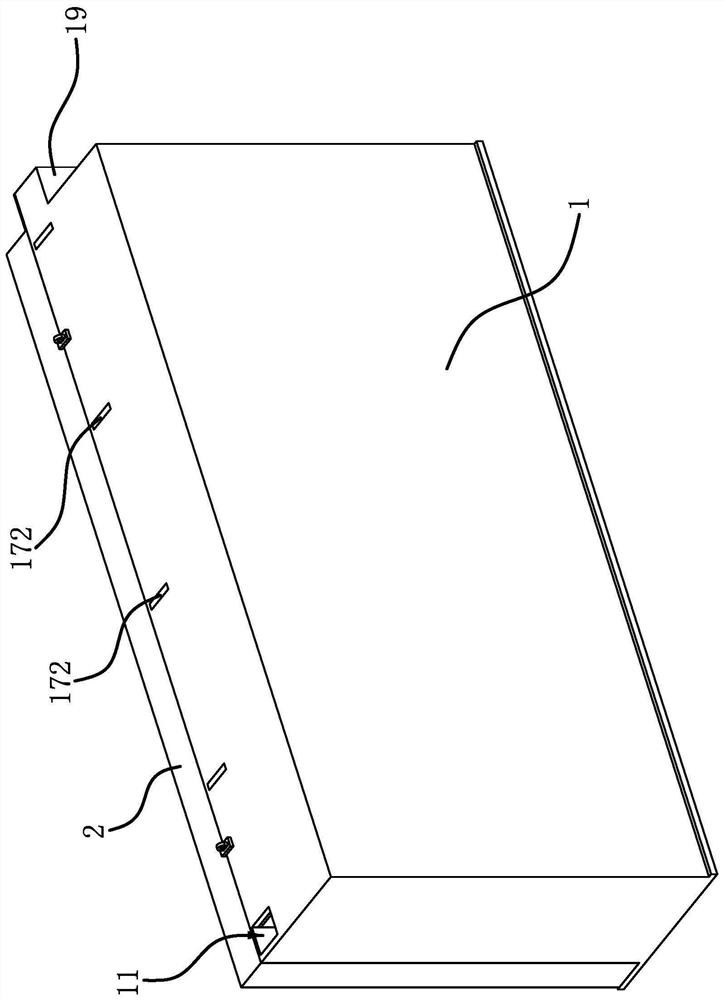

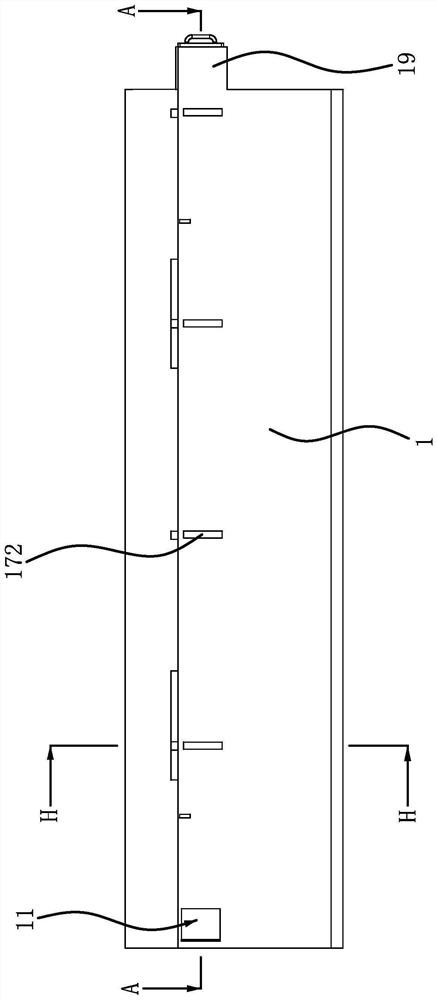

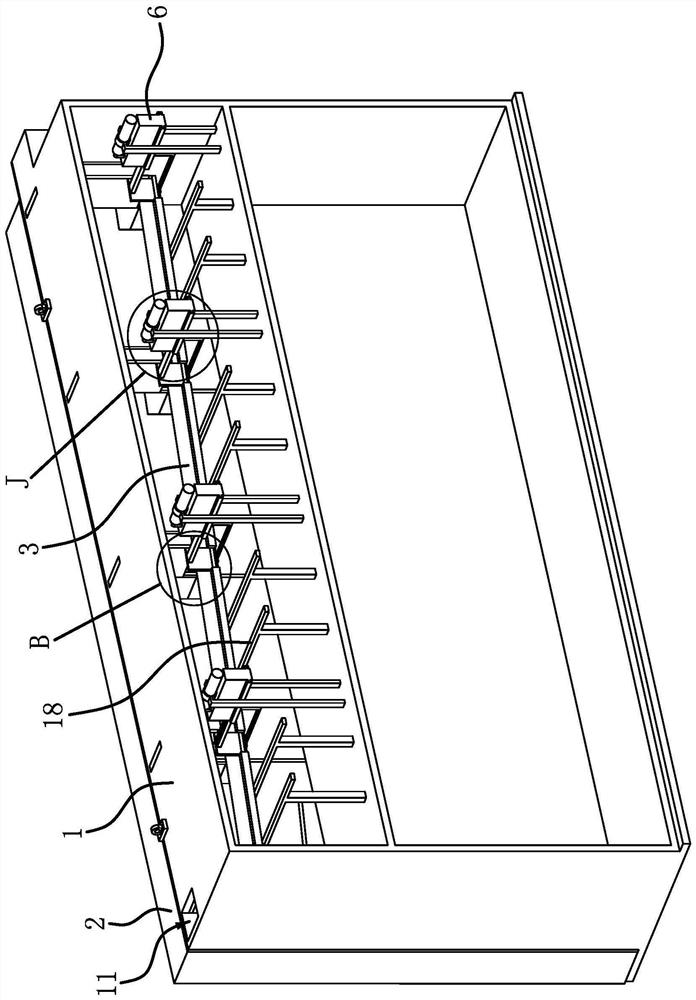

[0038] Such as Figure 1 to Figure 7 As shown, a channel structure of a waste battery recovery device, the waste battery recovery device includes a flat box 1 and a storage box 2, the rear side of the box 1 is open, and the storage box 2 is detachably connected to the The opening of the box body 1, that is, the lower part of the storage box 2 is plugged up and down through the plug and slot, and the upper part is buckled through the buckle plate. The storage box 2 is divided into several storage materials for storing different types of used batteries. Cavities 21, on the front side wall of the material storage box 2, there are also several feeding ports 22 corresponding to the plurality of material storage cavities 21 one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com