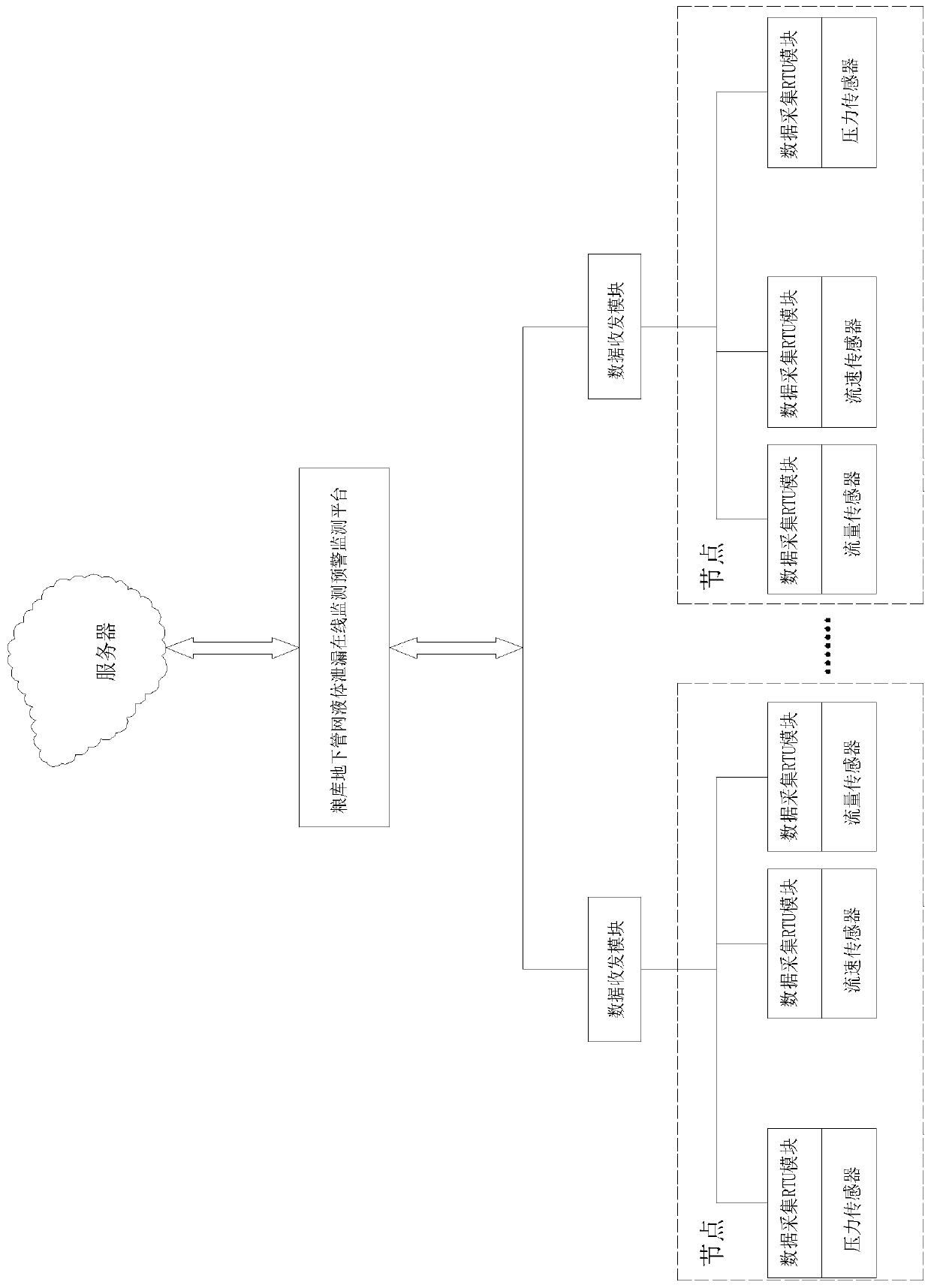

Online monitoring and early warning method and device of grain depot underground pipe network liquid leakage

An underground pipe network, monitoring and early warning technology, which is applied to measurement devices, liquid/vacuum measurement for liquid tightness, fluid tightness testing, etc. Achieve the effect of avoiding internal fluctuations in the pipeline, measurement errors, and accurate early warning results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] An online monitoring and early warning method for liquid leakage in an underground pipeline network of a grain depot, comprising the following steps:

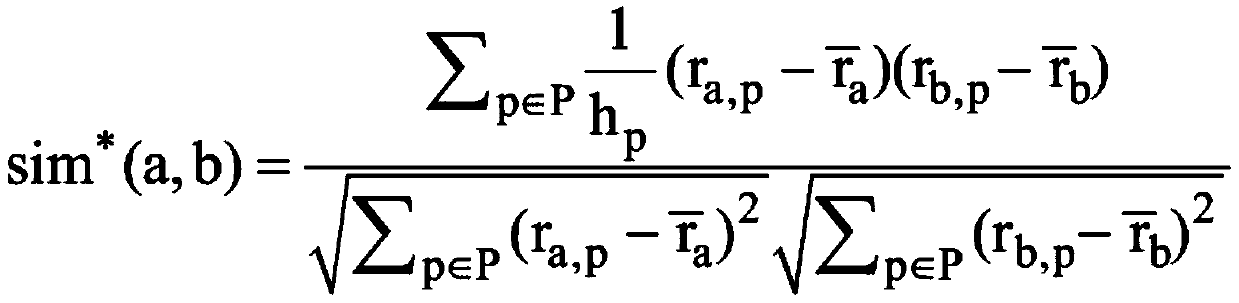

[0051] 1. Select the trusted neighbor set of the current node to be detected based on collaborative filtering, select the flow trusted neighbor set of the current node to be detected by using traffic as an item, and select the trusted neighbor set of the current node to be detected by using pressure as an item Velocity trusted neighbor set;

[0052] 2. Comparing the flow trusted neighbor set and pressure trusted neighbor set of the current node, select the same nodes in the flow trusted neighbor set and pressure trusted neighbor set to form the final trusted neighbor set;

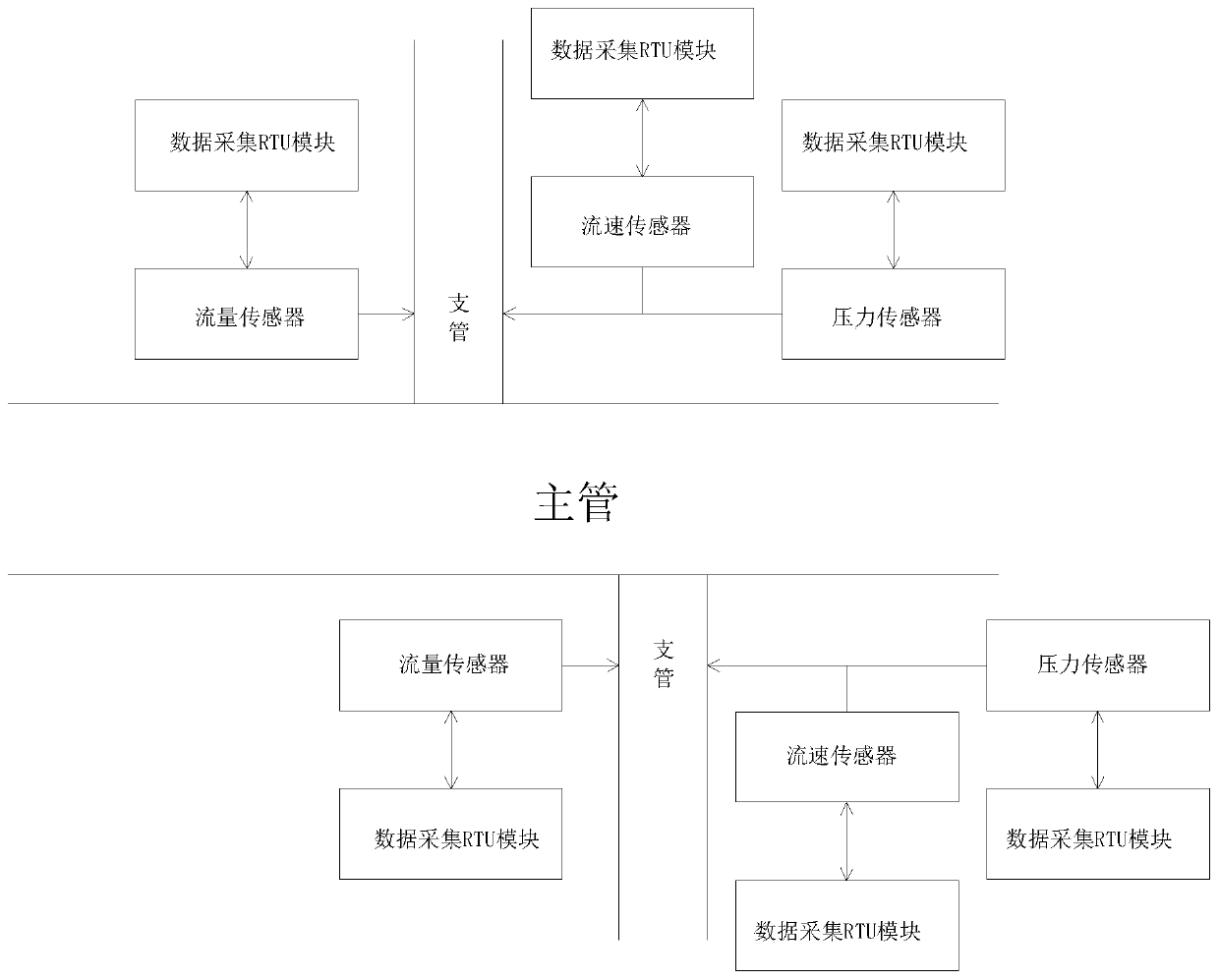

[0053] 3. According to the flow velocity difference between the current node and all nodes in the final trusted neighbor set during detection, count the number of nodes in the final trusted neighbor set whose flow velocity difference exceeds the flow ...

Embodiment 2

[0066] On the basis of Embodiment 1, a method for determining the flow velocity difference threshold is provided. The flow velocity of the nodes on the branch pipes with the same pressure and flow is theoretically consistent, but due to the influence of actual measurement errors and fluctuations, there will be a deviation of about 5%, which is desirable. The average value of the flow velocity difference of all nodes in the final trusted neighbor set is taken as the standard flow velocity difference. The abnormal node needs to increase the flow velocity to make up for the leakage loss. Therefore, it is desirable to select the flow velocity difference threshold as 107% of the standard flow velocity difference, which is greater than the threshold and deviates from the normal deviation , marked as abnormal.

Embodiment 3

[0068] On the basis of Embodiment 1, a method for determining the quantity threshold is provided. In theory, the quantity threshold is 1, but in reality there are errors and deviations and the influence of bad equipment, so the threshold can be appropriately increased, and can be carried out according to the number of branch pipes. Set, for example, the number of branch pipes on the main pipe is X, then the number threshold is X, and if the threshold is greater than the threshold, it will be marked as an abnormal node.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com