Blending hole adjustment system and method for adjusting combustion chamber outlet temperature distribution

A technology of outlet temperature and adjustment system, which is applied in combustion methods, combustion chambers, continuous combustion chambers, etc., can solve problems such as turbine guider/moving blade ablation, and improve the quality effect of the outlet temperature distribution of the combustion chamber and the cut-off effect , Improve the effect of outlet temperature distribution quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the purpose and effect of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings. It should be pointed out that the specific implementations described here are only used to explain the present invention, not to limit the present invention.

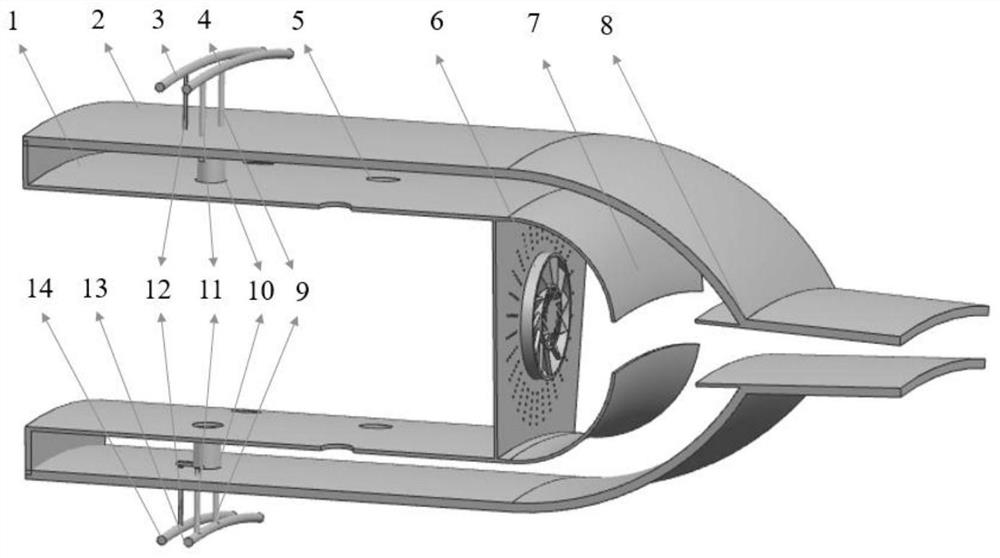

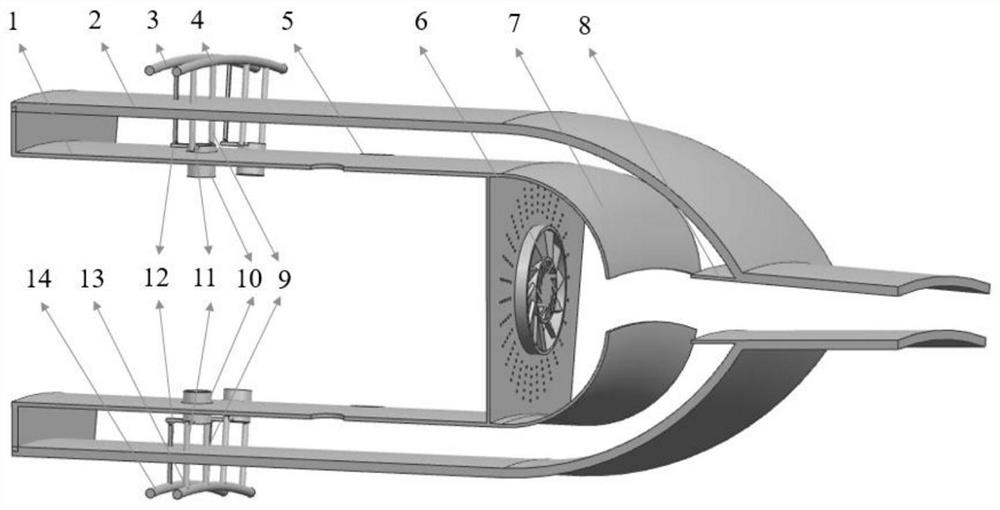

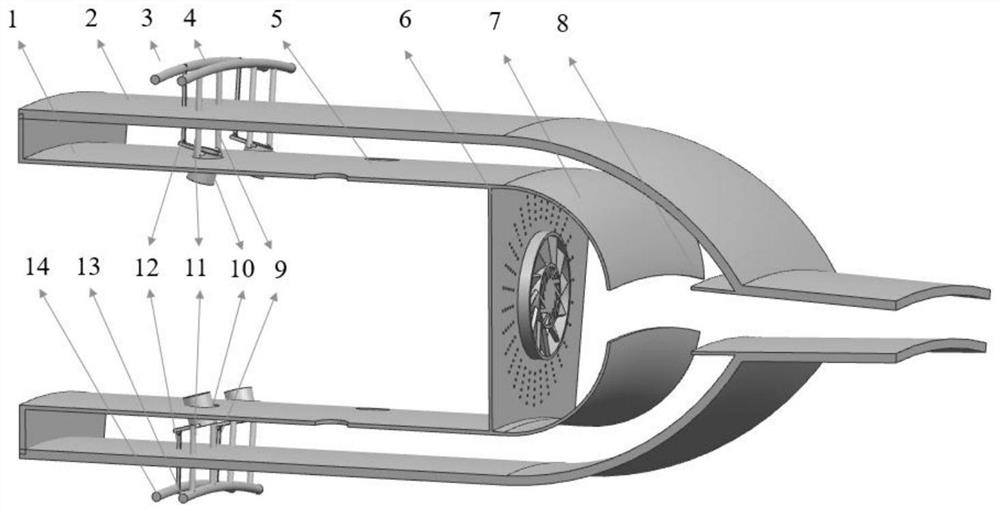

[0029] Such as figure 1 As shown, it is a schematic diagram of the non-activated state of the telescopic blending hole regulating system for adjusting the outlet temperature distribution of the combustion chamber of the present invention. The telescopic blending hole 10 is facing the blending hole on the traditional combustion chamber flame tube. The mixed hole is placed in the inner and outer ducts, and its spatial position is determined by the expansion and contraction of the first telescopic strut 9, the second telescopic strut (11) and the rotating strut 12; When increasing, according to the relationship between the calibrated c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com