Online TBM hob abrasion real-time detection system and method

A real-time detection and hob technology, applied in measuring devices, instruments, optical devices, etc., can solve problems such as complexity and inaccurate measurement accuracy, and achieve the effect of reasonable protective devices, reasonable system composition, and safe and efficient operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

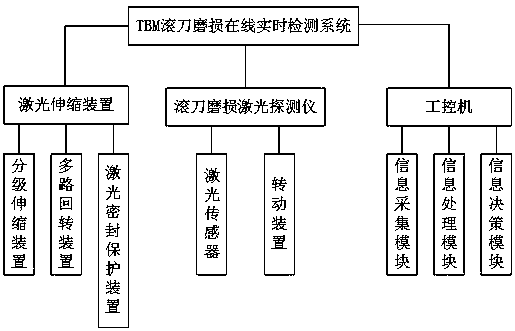

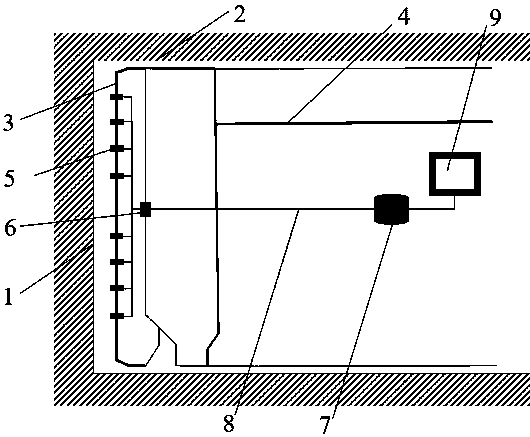

[0034] Example 1, such as figure 1 , image 3 , Figure 4 As shown, an online real-time detection system for TBM hob wear includes an industrial computer 7, which is set on the host platform 4, which is the TBM, and the industrial computer 7 realizes data collection and control command sending and transmission. The industrial computer 7 is respectively connected with the laser telescopic device in front of the TBM and the hob wear laser detector through the data cable 8. The industrial computer 7 controls the free hierarchical expansion and contraction of the laser telescopic device. The wear state of the laser is sent to the industrial computer 7, and the number of the laser telescopic device and the hob wear laser detector is set to several. The laser telescopic device is distributed and installed on the TBM cutter head 3, and multiple lasers can be set according to the setting of the detection point. retractable device. Mounting holes are arranged on the TBM cutter head ...

Embodiment 2

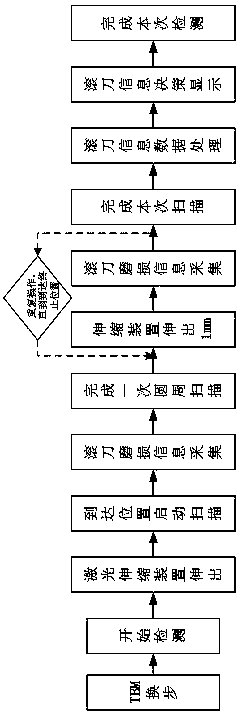

[0042] Embodiment 2, an online real-time detection method for TBM hob wear, the steps are as follows:

[0043] Step 1: Arrange detection points on the TBM cutter head 13 according to the layout of the TBM cutter head 13, install a laser telescopic device at each detection point, and install the hob wear laser detector on the top of the laser telescopic device; the layout of the detection points They are evenly distributed on the cutter head and arranged reasonably according to the type of cutter head to ensure that the arrangement of these detection points can cover all hob cutter positions.

[0044] Step 2: When it is necessary to change steps in the first ring of TBM excavation, the hob wear detection can be carried out at this time, and the switch of the hob measuring device in the TBM main control room 9 is turned on, and the industrial computer 7 controls the extension of the laser telescopic device to extend rapidly To the limit wear standard of the 13-side cutter of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com