Device and method for real-time monitoring of airflow angle in three-dimensional flow field based on micro-fan-shaped probe

A real-time monitoring, three-dimensional flow field technology, used in measurement devices, aerodynamic tests, and testing of machine/structural components, etc., can solve problems such as increased flow loss, loss of engine thrust, and loss of lift of aircraft, and achieves easy docking. , the effect of high frequency response and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

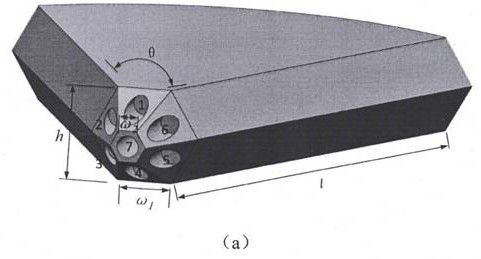

[0038] The present invention will be further described below by taking the fan-shaped probe installed at the lip of the air intake of an aeroengine as an example, in conjunction with the accompanying drawings.

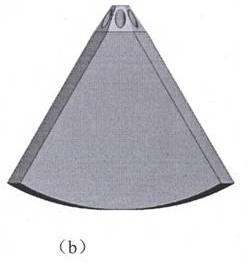

[0039] 1. Design the fan-shaped probe shape

[0040] Before designing the shape of the fan-shaped probe, the thickness of the boundary layer at the lip of the inlet is determined through wind tunnel experiments at common airflow angles. Use the displacement mechanism to move the boundary layer probe along the normal direction of the wall, with a step length of no more than 1 mm, and measure the boundary layer parameters at the lip of the air intake by combining the boundary layer probe and the static pressure hole on the lip wall. Based on the fluid mechanics theory that the static pressure gradient along the normal direction of the wall in the boundary layer is zero, it is considered that the indication of the static pressure hole represents the indication of the stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com