A photovoltaic battery power supply device and method

A photovoltaic cell and power supply device technology, applied in the field of photovoltaic cell power supply devices and variable voltage sources, can solve the problems of photovoltaic cell power generation energy loss and unsustainable power generation, achieve continuous power generation, ensure maximum power output, and improve energy recovery. Yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

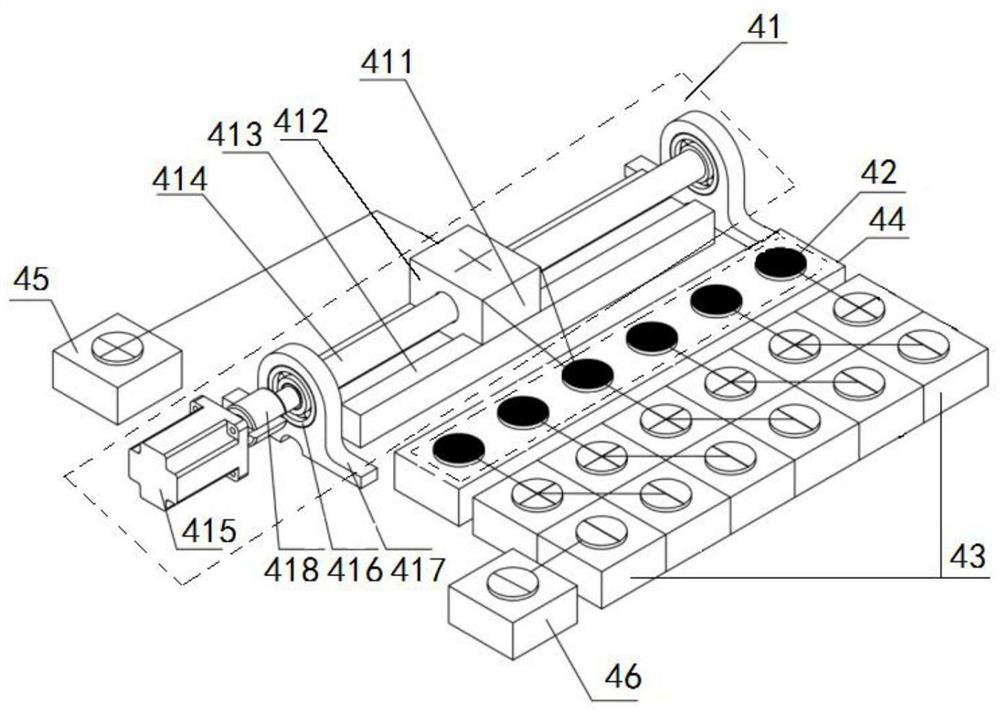

[0042] Such as figure 1 As shown, a variable voltage source 4 includes a contact selection device 41, a metal contact group 42 and a battery row 43;

[0043] Among them, the metal contact group 42 is connected to the battery discharge 43; the metal contact group 42 includes a plurality of metal contacts; the battery row is composed of a plurality of batteries connected in series; the voltage from the first metal contact to the last metal contact increases sequentially;

[0044] In this embodiment, metal contacts and batteries can be connected in one-to-one correspondence, that is, each battery corresponds to a metal contact;

[0045]As an optional implementation, the voltage difference between two adjacent metal contacts is at least twice the voltage of a single battery, and the voltage from the first metal contact to the last metal contact increases in equal increments, that is, the voltage difference between two adjacent metal contacts The number of batteries connected in s...

Embodiment 2

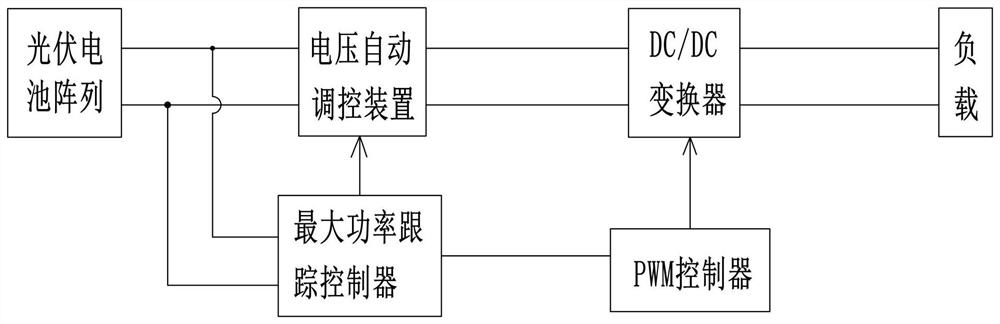

[0056] Such as figure 2 As shown, the photovoltaic cell power supply device shown in this embodiment includes a photovoltaic cell array, an automatic voltage regulation device, a DC / DC converter, a maximum power tracking controller, a PWM controller and a load;

[0057] Among them, the photovoltaic cell array, the automatic voltage control device, the DC / DC converter and the load are connected in sequence, one end of the maximum power tracking controller is connected to the photovoltaic cell array, one end of the maximum power tracking controller is connected to the PWM controller, and the voltage is automatically regulated The device is controlled by the maximum power tracking controller, and the DC / DC converter is controlled by the PWM controller;

[0058] The maximum power tracking controller is used to find the maximum power point of the photovoltaic cell array. When the maximum power point is found, it sends a control signal to the automatic voltage regulation device to ...

Embodiment 3

[0065] Such as Figure 5 Shown, a kind of photovoltaic battery power supply method, comprises the following steps:

[0066] S1: Obtain the maximum power point of the photovoltaic cell array;

[0067] S2: Determine the corresponding voltage value according to the maximum power point of the photovoltaic cell array, and adjust the terminal voltage of the variable voltage source in the voltage automatic regulation device to the corresponding voltage value;

[0068] This step specifically includes:

[0069] Control the rotation angle of the stepper motor in the variable voltage source in the voltage automatic regulation device, so that the slider on the lead screw slides, the contacts on the slider contact the corresponding metal contacts, and the variable voltage source The terminal voltage is adjusted to the corresponding voltage value;

[0070] S3: Use the DC / DC converter to receive the output voltage of the automatic voltage regulation device, and control the boost ratio by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com