Self-snow-removing greenhouse structure

A technology for greenhouses and roof panels, which is used in greenhouse cultivation, snow traps, building structures, etc., can solve the problems of temperature and light intensity drop, collapse, slow melting of snow, etc., so as to improve production effect and improve light transmission. effect, effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

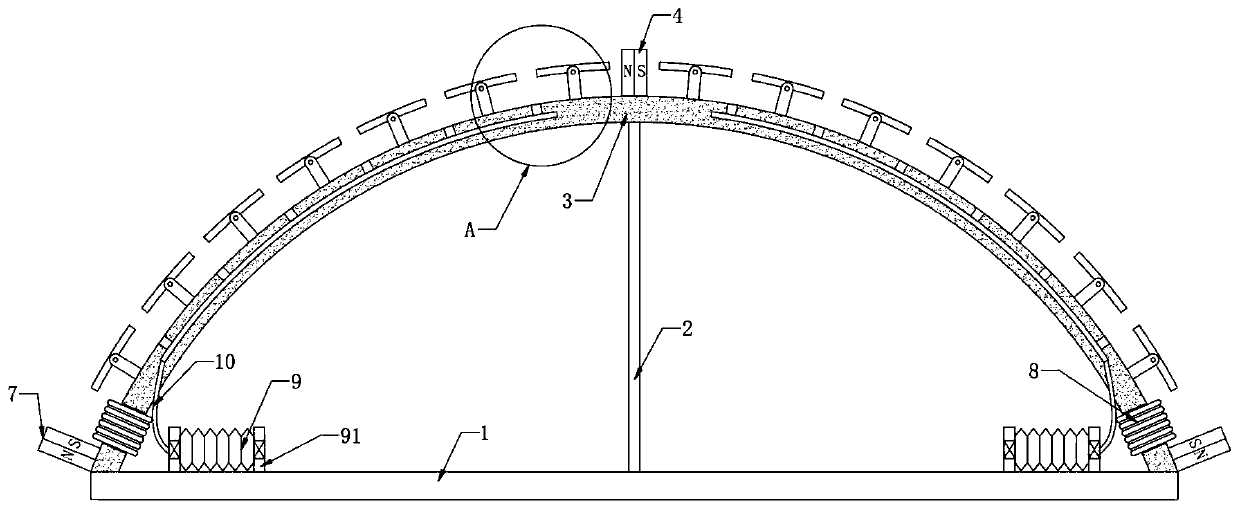

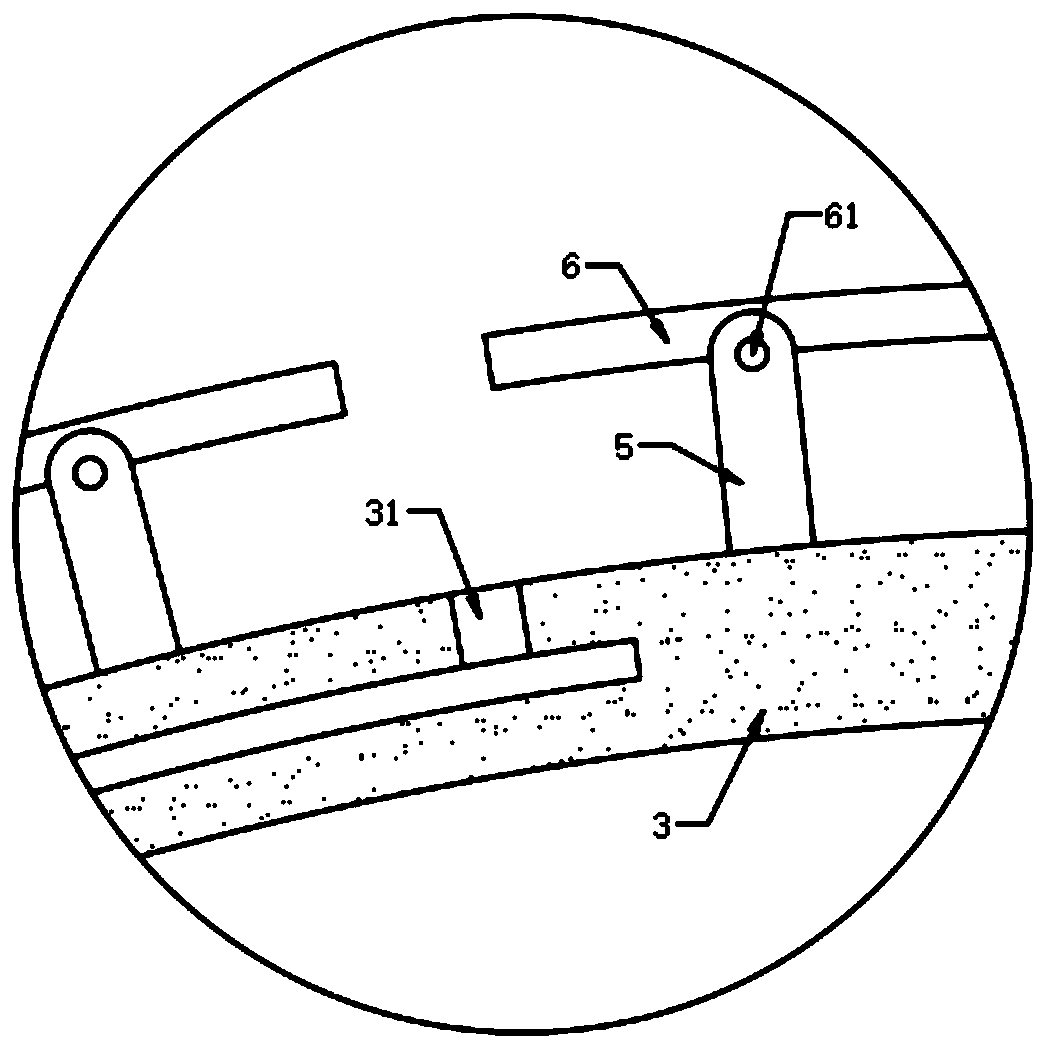

[0021] refer to Figure 1-2 , a self-removing snow greenhouse structure, comprising a base 1, the upper end of the base 1 is welded with a support rod 2, the upper end of the support rod 2 is provided with a roof plate 3, and the upper end of the roof plate 3 is provided with a first electromagnet 4, Both sidewalls of the ceiling board 3 are provided with a second electromagnet 7, and the first electromagnet 4 and the second electromagnet 7 are opposite to each other when they are energized. The side wall of 5 is rotatably connected with snow shield 6 through spring shaft 61, and snow shield 6 is made of silicon steel sheet.

[0022] It should be noted that no matter what the direction of the magnetic field is, the snow shield 6 is made of silicon steel sheets, and its magnetization direction always obeys the external magnetic field. During the negative peak value, the magnitude and direction of the magnetic force formed for the snow shield 6 are consistent, and the magnetic ...

Embodiment 2

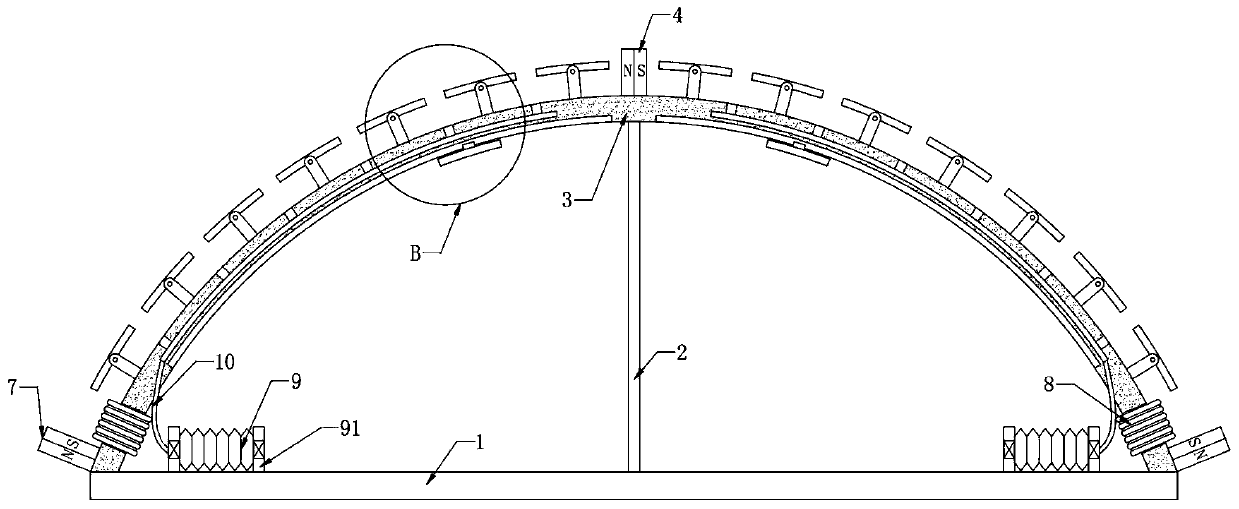

[0031] refer to Figure 3-4 The difference from the first embodiment is that a brush board 11 is slidably connected to the side wall of the ceiling board 3, the brush board 11 is made of magnetic material, and a sponge strip is fixedly connected to the brush board 11.

[0032] Specifically, a guide groove 32 is provided on the inner side wall of the ceiling board 3 , and a guide block 111 is slidably connected in the guide groove 32 , and the lower end of the guide block 111 is fixedly connected with the brush plate 11 .

[0033] In this embodiment, when the current direction leading to the first electromagnet 4 and the second electromagnet 7 changes, the magnetic poles of the first electromagnet 4 and the second electromagnet 7 also change accordingly, and because the first electromagnet 4. It is opposite to the opposite magnetic pole of the second electromagnet 7, so that under the action of magnetic force, the brush plate 11 made of magnetic material can slide back and fort...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com