Microwave sterilization equipment for non-woven fabric production and processing

A technology of microwave sterilization and non-woven fabrics, which is applied in sanitary equipment for toilets, water supply devices, buildings, etc., and can solve problems such as adjustment, air generation between non-woven fabrics and placement surfaces, and inability to guide non-woven fabrics into them.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

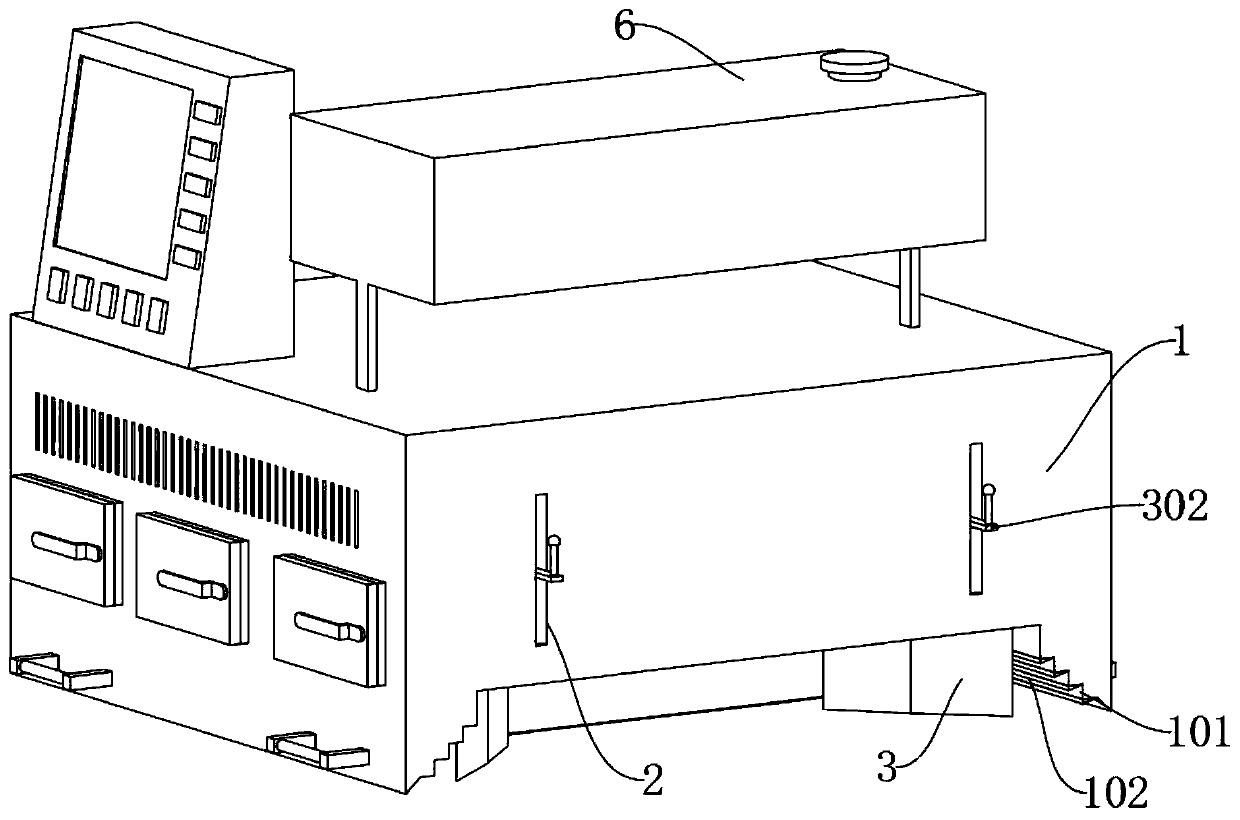

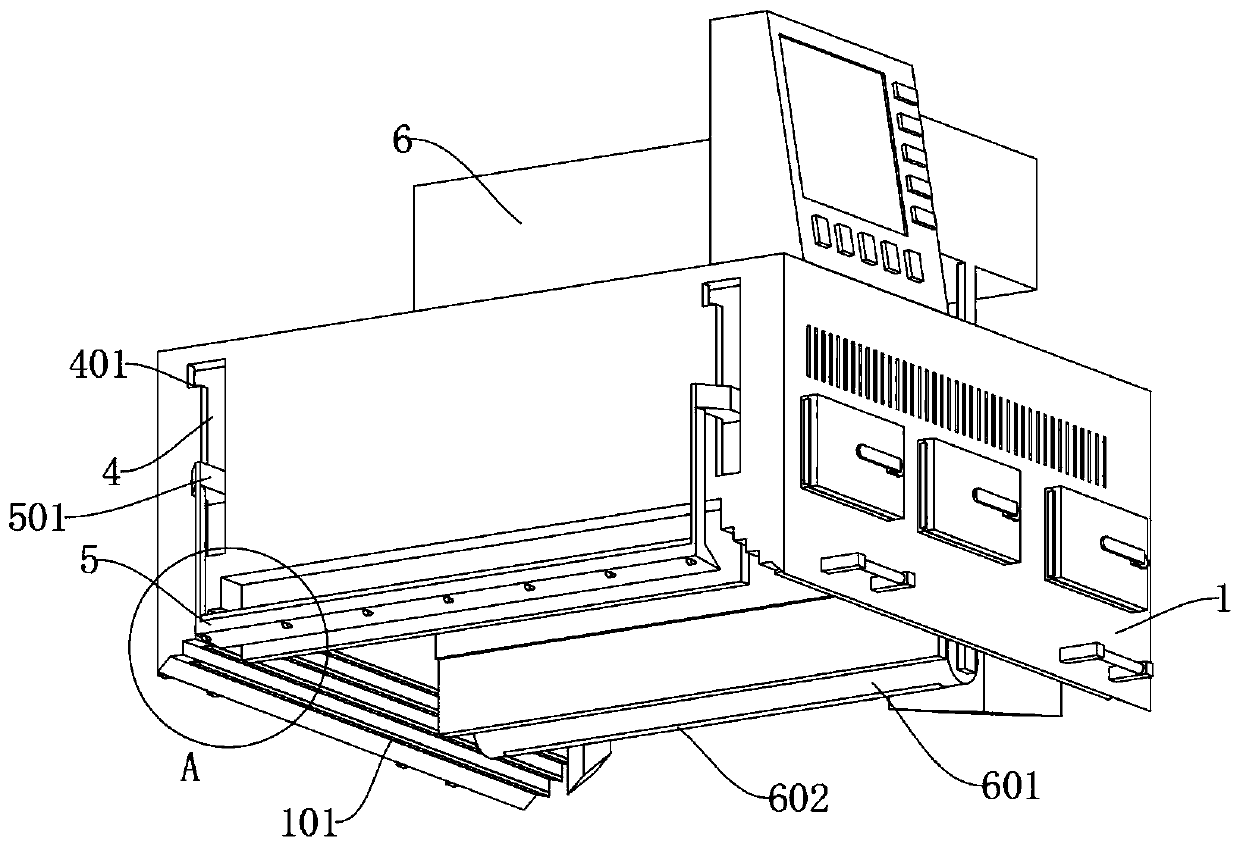

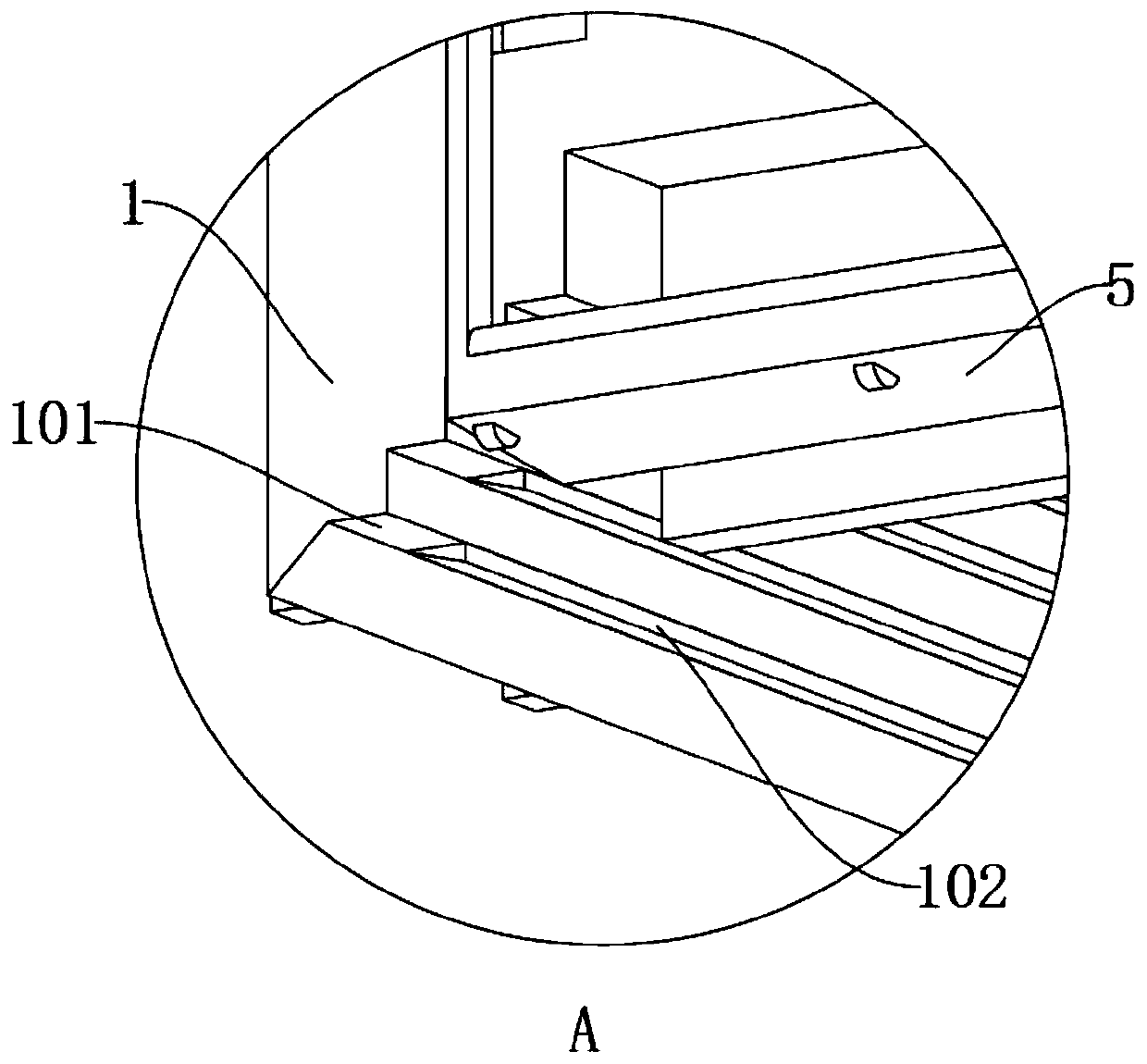

[0030] as attached figure 1 to attach Figure 8 Shown:

[0031]The invention provides a microwave sterilization equipment for the production and processing of non-woven fabrics, which includes: a main body 1, a side groove 2, a turning plate 3, a rear groove 4, a contact piece 5 and a water tank 6; the main body 1 is a rectangular structure, and the main body 1 is a microwave The main body of the sterilization equipment, and the seal 102 at the bottom of the bottom tank 101 is used to directly contact with the top sides of the production line, so that after the main body 1 is installed, the gap can be sealed, and it can also play a role in preventing slipping, so that the main body 1 can Effective installation and use; side slots 2 are located on both sides of the front end of the main body 1, and the bottom of the side slots 2 is at the bottom of the main body 1, and the slot 201 is used to insert the inner end of the control board 302, so that the control After the board 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com