Horizontal table board capable of maintaining temperature balance

A temperature balance, water platform technology, used in the testing of machine/structural components, measuring devices, vibration testing, etc., can solve problems such as reducing system reliability, guide rail damage, vibration system failure, etc., to improve reliability and solve damage. , the effect of improving rigidity and bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

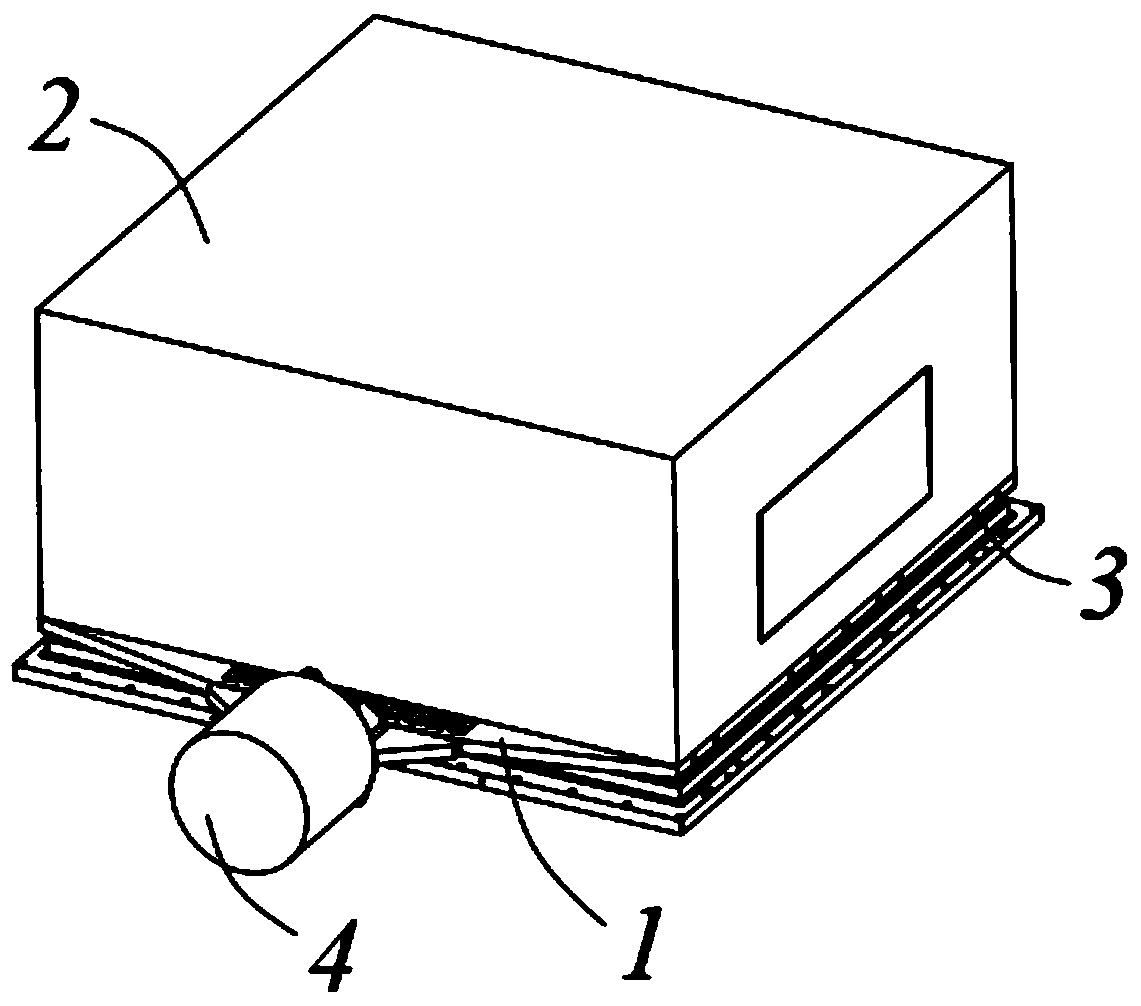

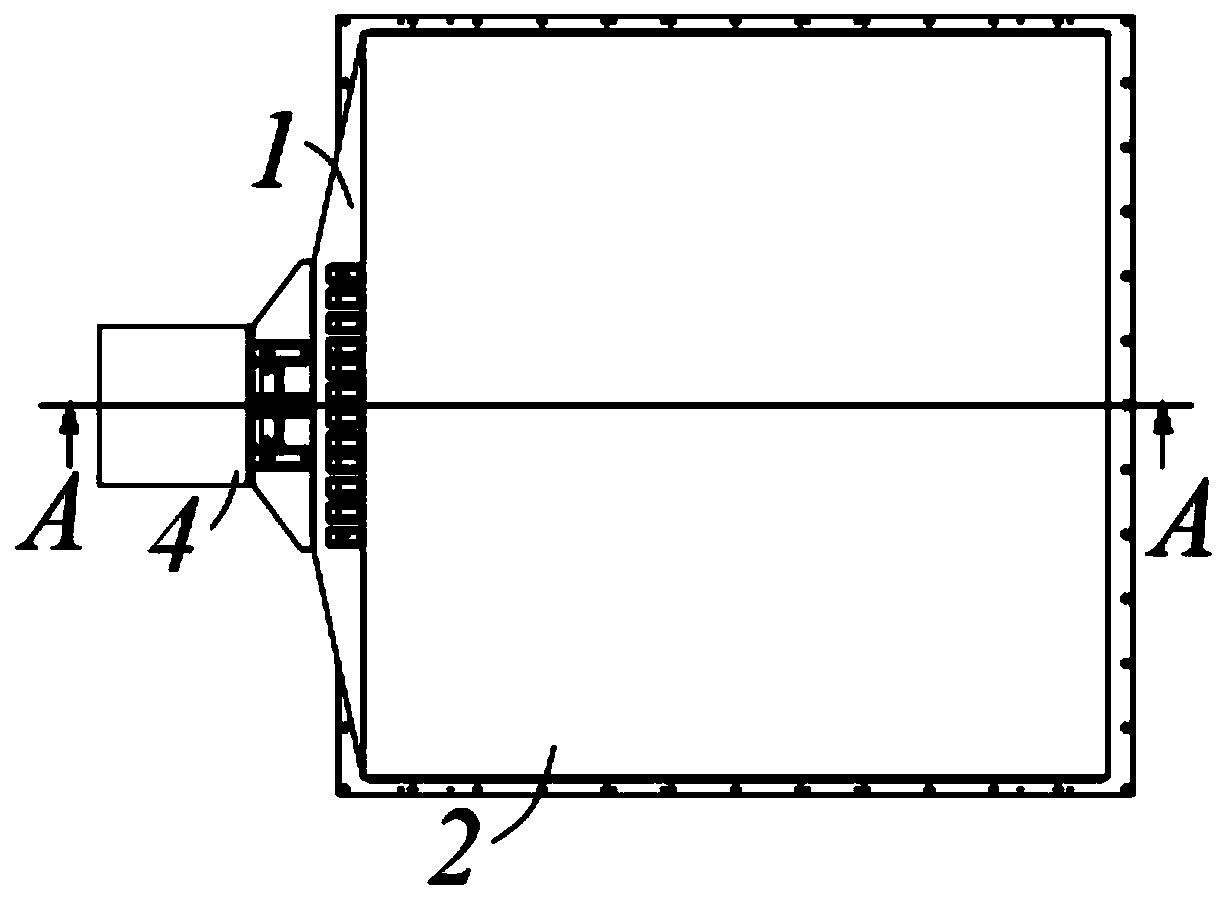

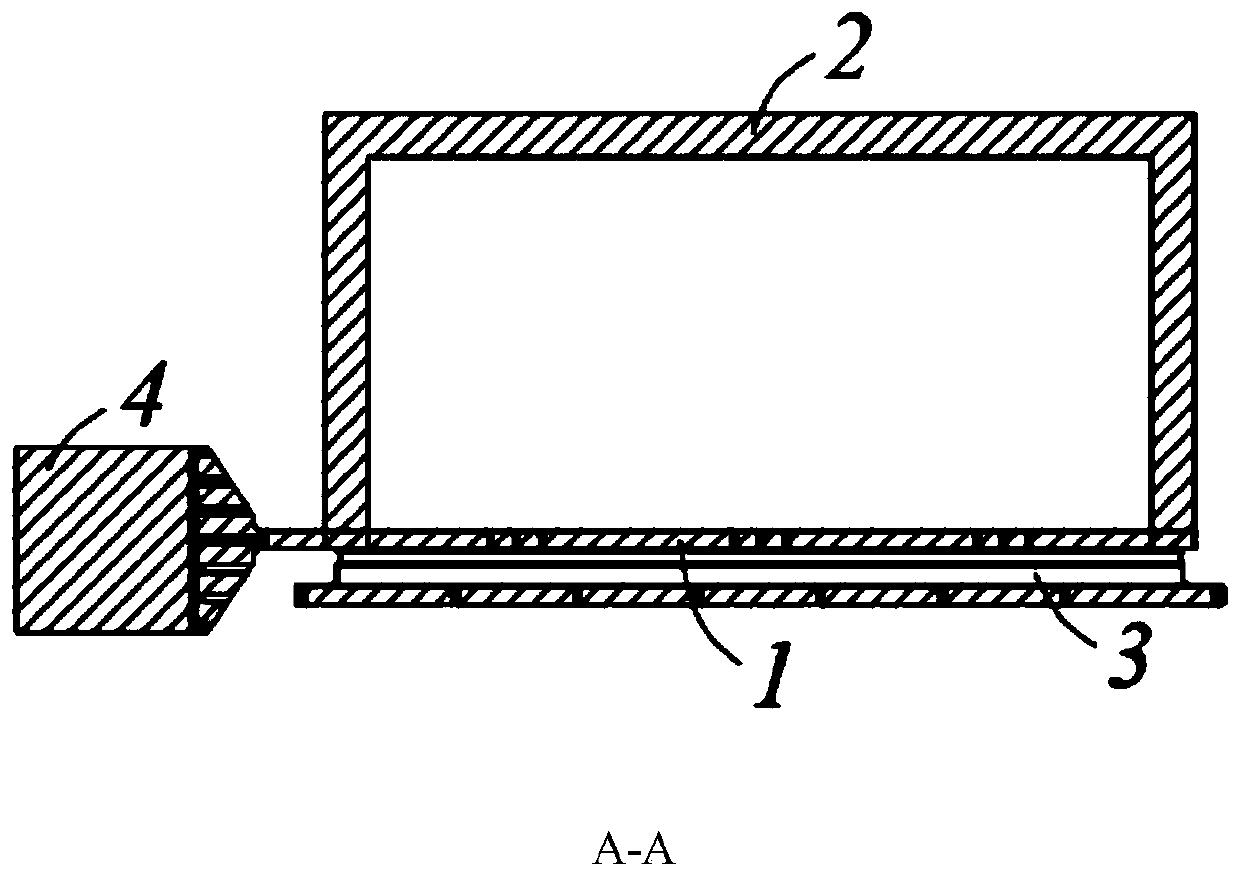

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0022] Figure 4 and Figure 5 Shown is a horizontal platform that can maintain temperature balance, with a horizontal platform 1 body, the top surface of the horizontal platform 1 is a horizontal installation surface for installing test pieces, and a number of connecting holes 11 are provided at the right end; the horizontal platform 1 The bottom surface is provided with an electric heating sheet 14 and a number of uniformly densely distributed grids 13 to form a grid-like bottom surface. The horizontal platform 1 is flat. For the convenience of installing the electric heating sheet 14, the thickness h of the horizontal platform 1 is 90mm -100mm, while the thickness of the general horizontal platform is 50mm-60mm, which increases the thickness and facilitates the design of the grid 13, while the horizontal platform 1 with the grid-like bott...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Insulation resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com