Steel surface polishing processing equipment

A technology for surface polishing and processing equipment, applied in metal processing equipment, grinding/polishing equipment, surface polishing machine tools, etc., can solve the problems of reducing the flatness of stainless steel, flying cheap, affecting the smoothness of stainless steel, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

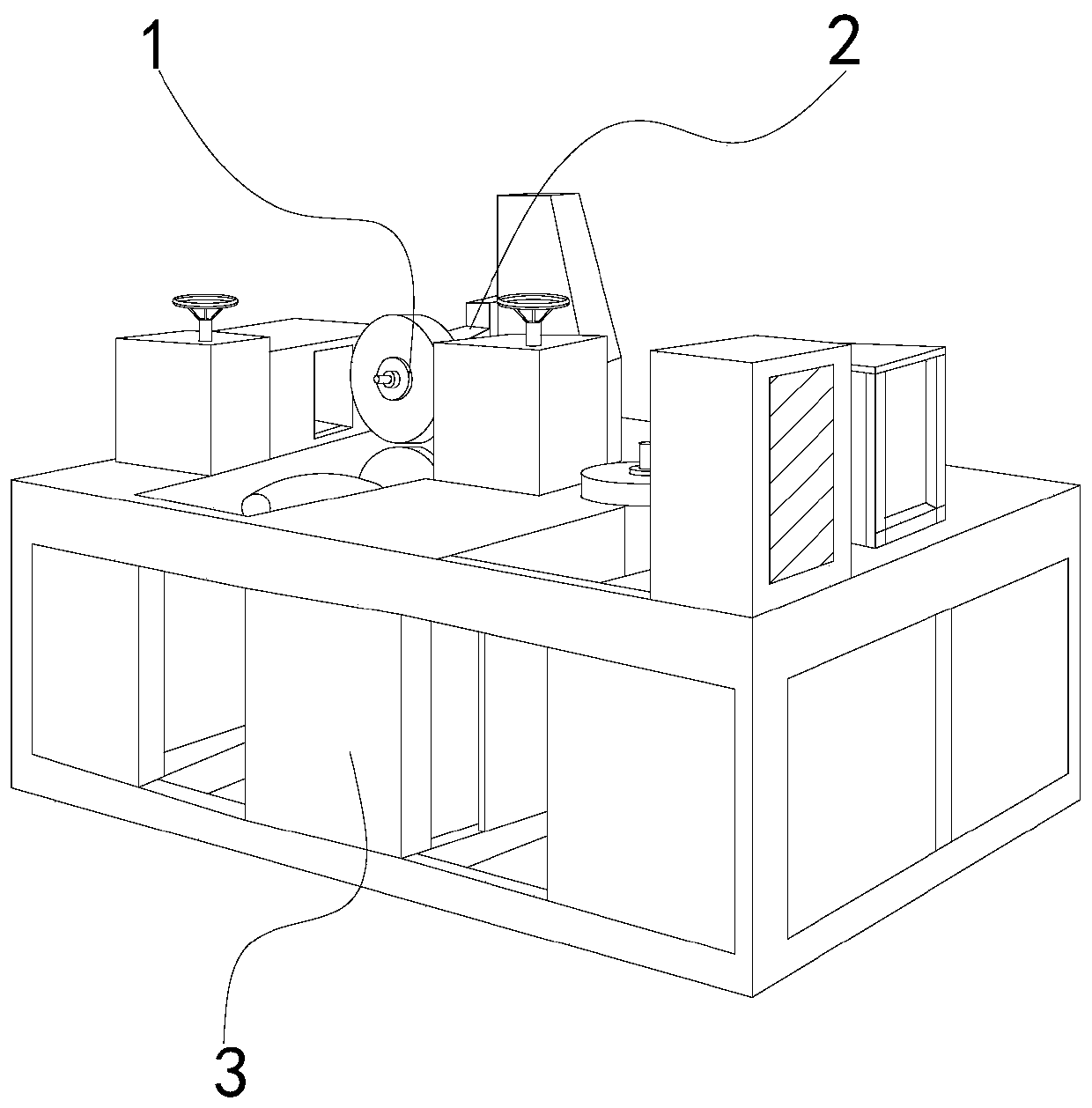

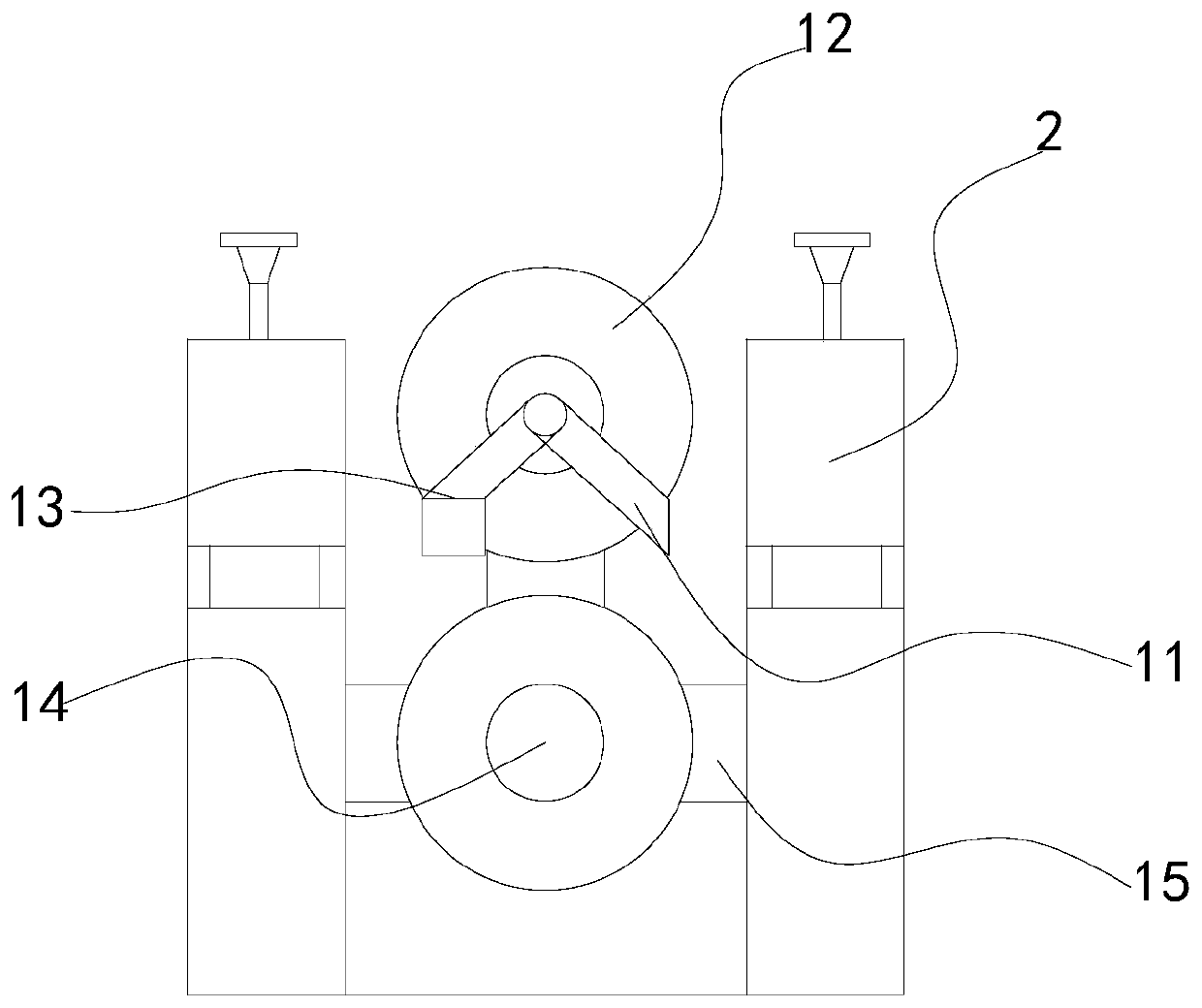

[0025] Such as Figure 1-Figure 4 Shown:

[0026] The present invention is an equipment for steel surface polishing. Its structure includes a polishing device 1, an adjuster 2, and a bracket 3. The adjuster 2 is installed on both sides of the polishing device 1, and the polishing device 1 is embedded in the bracket 3. The upper end of the adjuster 2 is welded on the upper surface of the bracket 3. The polishing device 1 is composed of a cleaning device 11, a polishing wheel 12, a sweeper 13, a sliding shaft 14, and a fixed plate 15. The cleaning device 11 is located in the polishing On both sides of the wheel 12, the upper end of the sweeper 13 and the upper end of the cleaning device 11 are located on the same central axis, the sliding shaft 14 is installed in the middle of the fixed plate 15, and the sweeper 13 is located on the left side of the polishing wheel 12. The fixed plate 15 is embedded in the lower inner side of the adjuster 2, the lower end of the cleaning device...

Embodiment 2

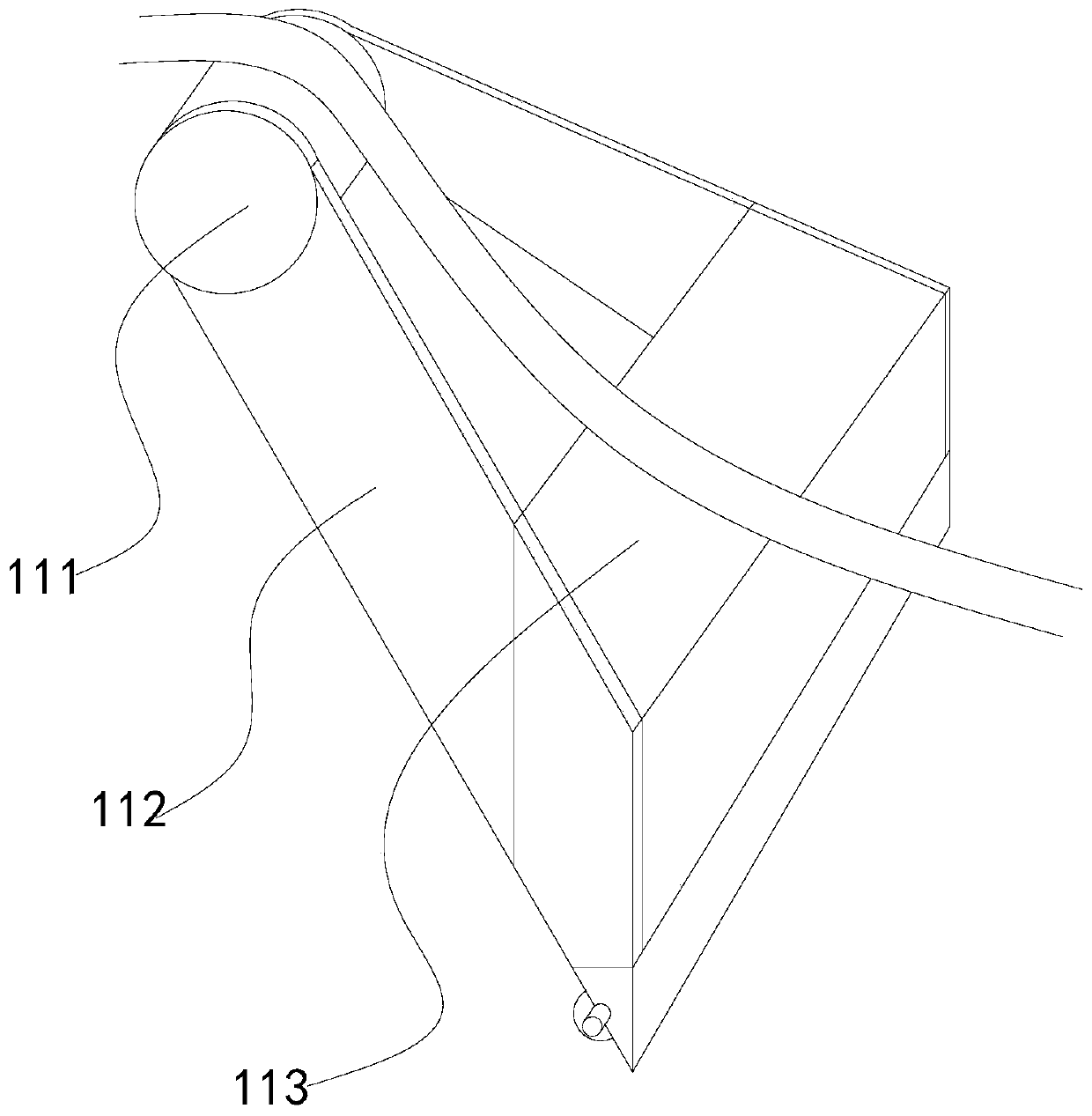

[0032] Such as Figure 5-Figure 8 Shown:

[0033] Wherein, the sweeper 13 is provided with a curved plate 131, a sweeping mechanism 132, a triangular block 133, an embedded plate 134, and a supporting plate 135, and the two ends of the curved plate 131 are welded on the inner side of the supporting plate 135, and the embedded The plate 134 is embedded in the lower end of the support plate 135, the cleaning mechanism 132 is embedded in the inner side of the embedded plate 134, the triangular block 133 is attached to the left lower end of the embedded plate 134, and the inner side of the support plate 135 Embedded on the outside of the polishing wheel 12, the curved plate 131 is a smooth surface structure, and the lower end is matched with the internal clearance of the sweeping mechanism 132, so that the cleaned abrasive debris can slide from the curved plate 131 to the surface of the sweeping mechanism 132 to avoid abrasive debris Accumulated inside the lower end of the sweepi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com