Preparation method of basic nickel carbonate with low fluidity and high solubility

A high-solubility, low-fluidity technology, applied in nickel carbonate and other directions, can solve the problems of flying dust and easy material leakage, and achieve the effect of obvious material leakage, less equipment corrosion, and reducing the total feeding time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] A kind of low fluidity of the present invention, the preparation method of the basic nickel carbonate of high solubility comprises the following steps:

[0018] (1) Preparation of nickel salt solution: nickel sulfate crystals are dropped into water to obtain nickel salt solution; the nickel salt in the nickel salt solution is one or more of nickel chloride, nickel sulfate, nickel nitrate; nickel in the nickel salt solution The ion concentration is 105g / L-110g / L.

[0019] (2) Prepare carbonate solution: put sodium carbonate solid into water to prepare carbonate solution; the concentration of carbonate in the carbonate solution is 210g / L-220g / L. Preferably, the carbonate solution is sodium carbonate solution.

[0020] (3) The nickel salt solution in step (1) and the carbonate solution in step (2) are accurately added to the reaction kettle with the bottom liquid through the metering pump in parallel flow to carry out the co-precipitation reaction. Liquid is the nickel s...

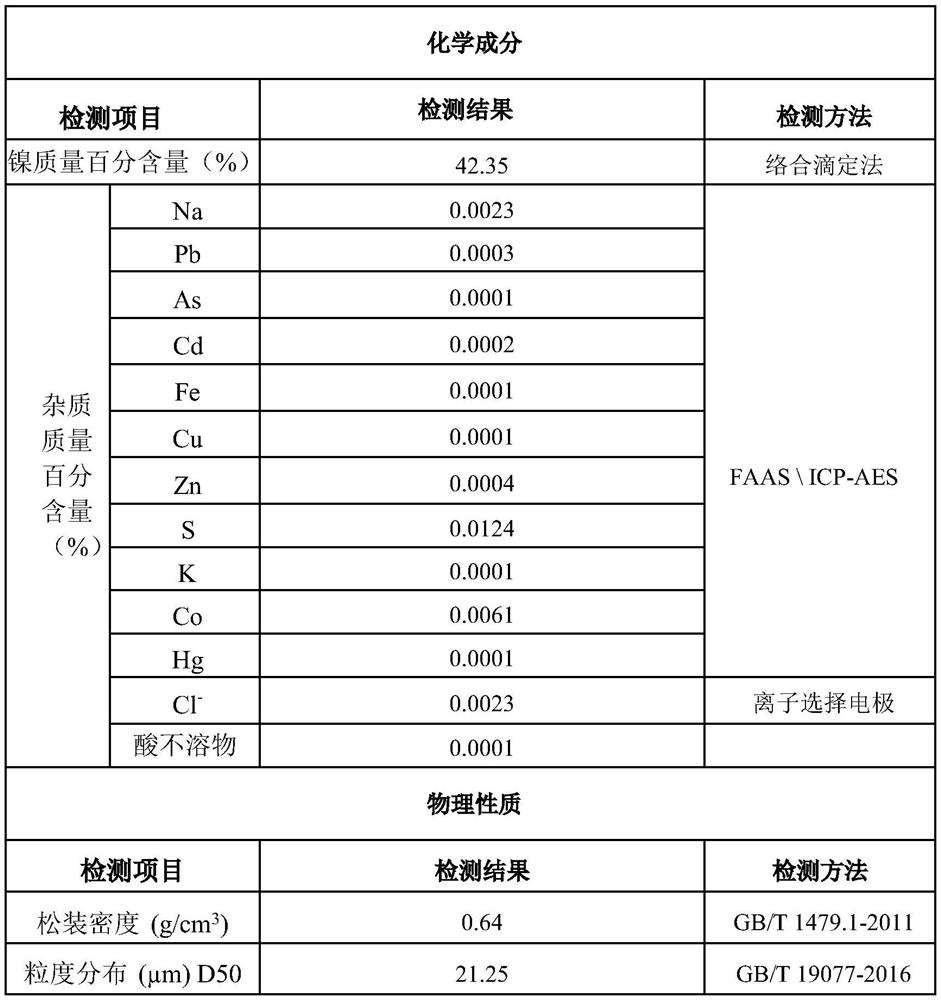

Embodiment 1

[0025] Add the nickel salt solution with a nickel ion concentration of 105g / L and the sodium carbonate solution with a concentration of 210g / L into the 6m 3 Co-precipitation reaction was carried out in the reaction kettle to obtain basic nickel carbonate slurry, the bottom liquid was nickel salt solution diluted with water, and the addition amount of the bottom liquid was 1.2m 3 , the diameter of the stirring blade of the reactor is 600mm; the reactor is single-layer stirring, and the feeding pipe of the reactor is flush with the single-layer stirring blade. The concentration of nickel ions in the bottom liquid is 21g / L; the feed flow rate of nickel salt solution added to the reactor is 350kg / h, and the feed rate of sodium carbonate solution added to the reactor is adjusted to 455kg according to the actual pH value of the reactor / h-500kg / h, the technological conditions of the co-precipitation reaction are: the reaction pH is 8.05-8.25, the reaction temperature is 53°C, the re...

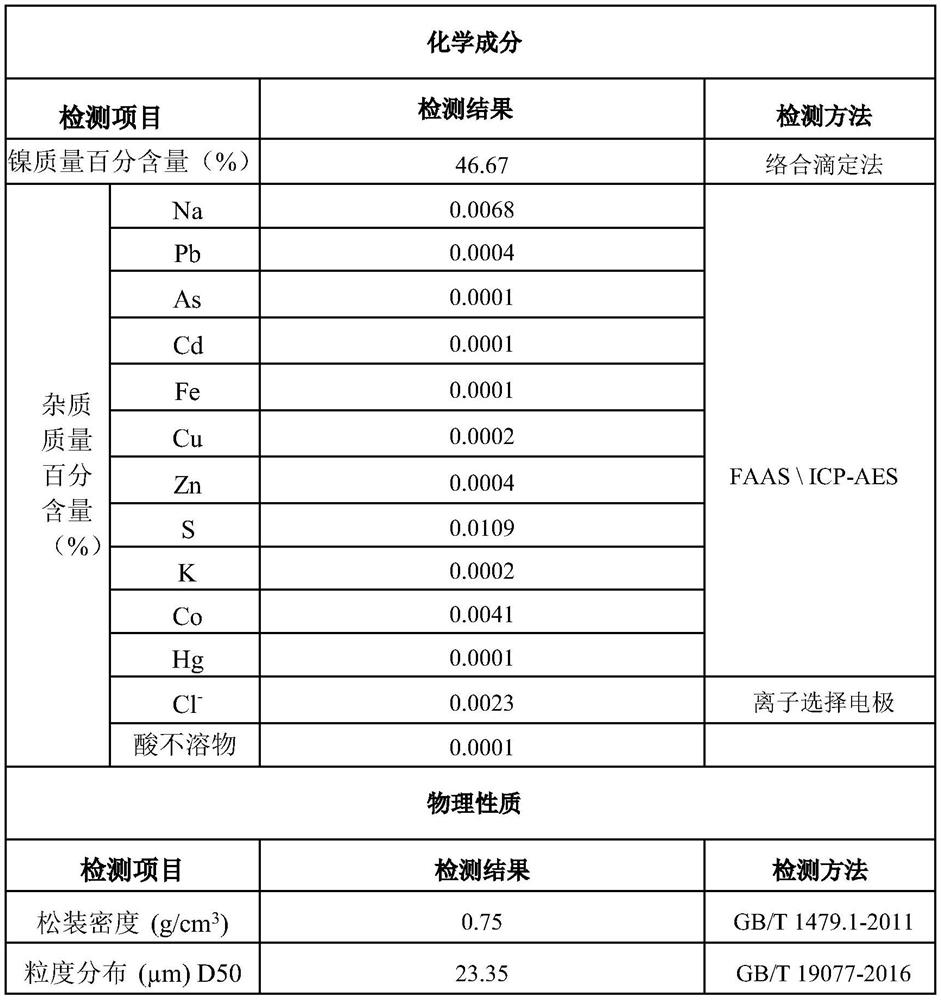

Embodiment 2

[0029] Add a nickel salt solution with a nickel ion concentration of 110g / L and a sodium carbonate solution with a concentration of 220g / L into the 6m 3 Co-precipitation reaction was carried out in the reaction kettle to obtain basic nickel carbonate slurry, the bottom liquid was nickel salt solution diluted with water, and the addition amount of the bottom liquid was 1.2m 3 , The diameter of the stirring blade of the reactor is 620mm; the reactor is a single-layer stirring, and the feeding pipe of the reactor is flush with the single-layer stirring blade. The concentration of nickel ions in the bottom liquid is 22g / L; the feed flow rate of nickel salt solution added to the reactor is 350kg / h, and the feed rate of sodium carbonate solution added to the reactor is adjusted to 500kg according to the actual pH value of the reactor / h-600kg / h, the technological conditions of the co-precipitation reaction are: the reaction pH is 8.15-8.35, the reaction temperature is 53°C, the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com