Preparation method of cobalt carbonate for lithium ion battery

A lithium-ion battery and cobalt carbonate technology, which is applied in cobalt carbonate, battery electrodes, secondary batteries, etc., can solve problems affecting the performance of lithium cobalt oxide, achieve the effect of improving uniformity and reducing precipitation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

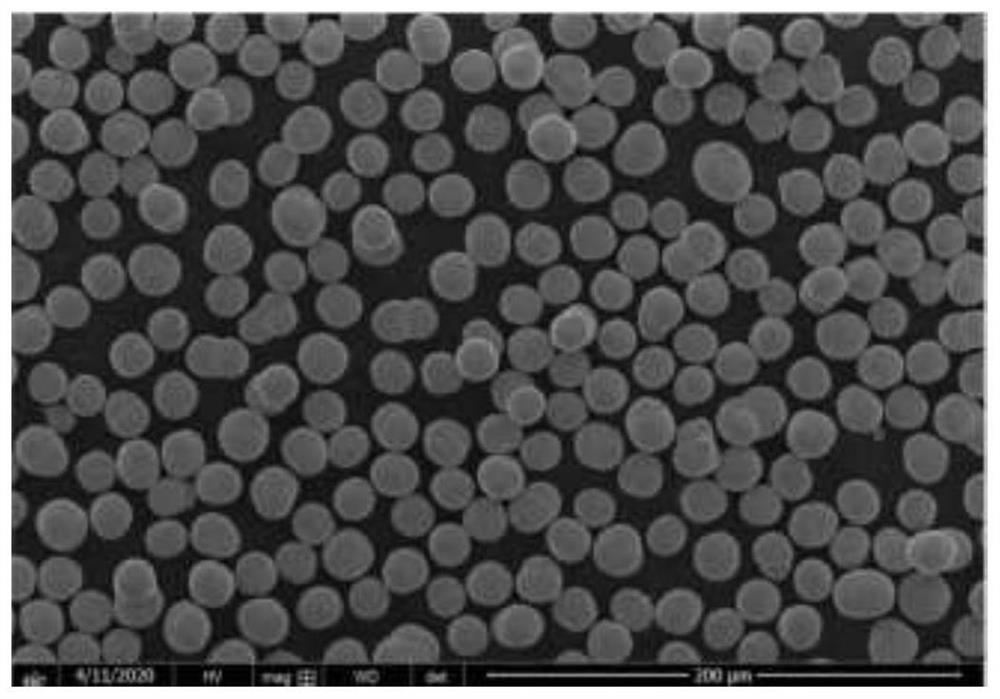

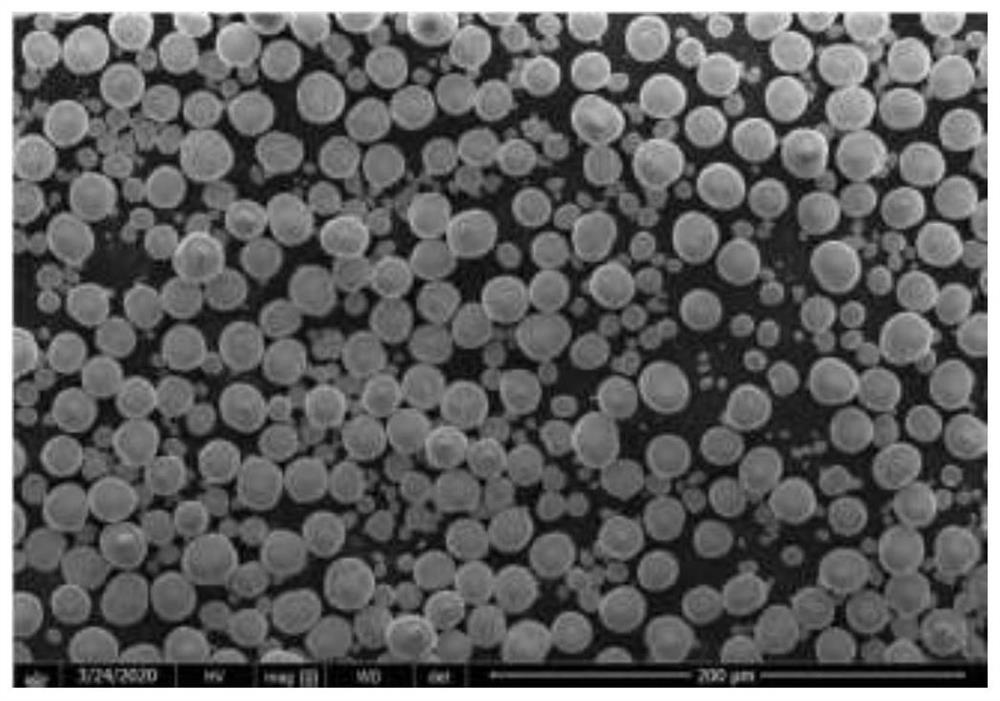

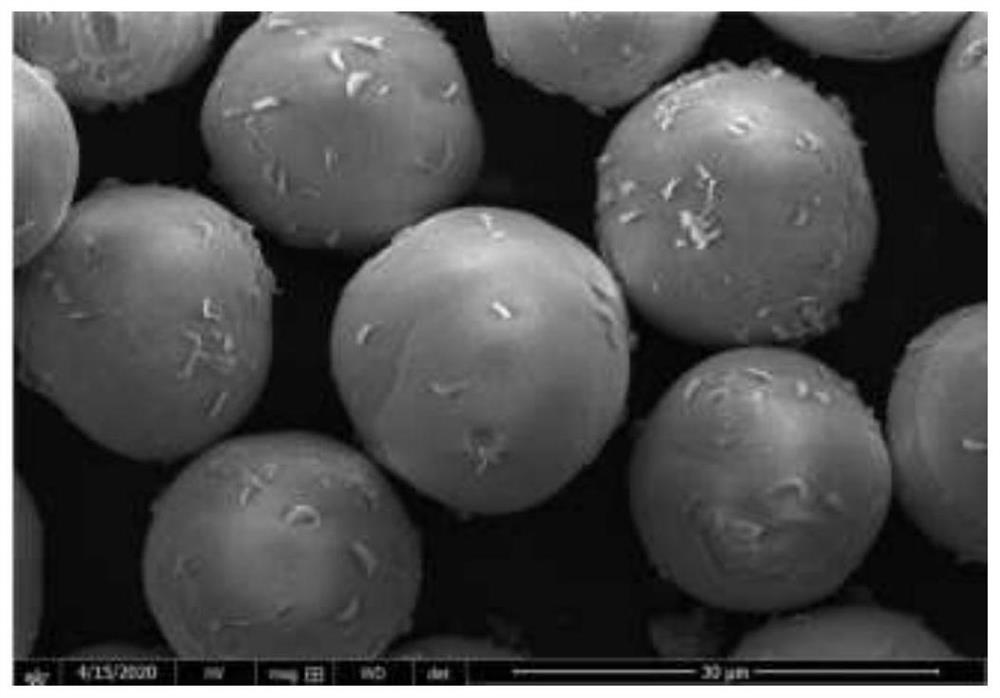

Image

Examples

Embodiment 1

[0028](1) Prepare aluminum sulfate solution with aluminum ion concentration of 2.7g / L;

[0029](2) Add cobalt sulfate solution and aluminum sulfate solution with a cobalt ion concentration of 90g / L, and a concentration of 200g / L ammonium bicarbonate solution. These three solutions are respectively added to the ammonium bicarbonate solution as a bottom liquid through a metering pump in a co-current manner In the reactor, the concentration of ammonium bicarbonate solution is 5g / L, the feed rate of cobalt salt solution is 50ml / min, the feed rate of aluminum salt solution is 25ml / min, and the feed rate of ammonium bicarbonate solution is 100ml / min. The reaction conditions of the reaction system of the co-precipitation reaction in the reactor are: pH 7.0-7.2, temperature 45°C, and reactor speed of 280 rpm. After 40 hours of reaction, the D50 particle size reaches 7 microns. Half of the materials are stored as seeds;

[0030]The remaining half of the materials continue to react in the reactor, ...

Embodiment 2

[0037](1) Prepare an aluminum sulfate solution with an aluminum ion concentration of 0.7g / L;

[0038](2) Cobalt chloride solution and aluminum sulfate solution with a cobalt ion concentration of 65g / L, and a concentration of 230g / L ammonium bicarbonate solution were added to the ammonium bicarbonate as the bottom liquid through a metering pump in a co-current manner. In the reactor, the concentration of ammonium bicarbonate bottom solution is 20g / L, the feed rate of cobalt salt solution is 50ml / min, the feed rate of aluminum salt solution is 60ml / min, and the feed rate of ammonium bicarbonate solution is 80ml / min The reaction conditions of the reaction system of the co-precipitation reaction in the reactor are: pH value 7.2-7.4, temperature 55°C, reactor speed 160rpm, after 40 hours of reaction, the D50 particle size reaches 6 microns, and then the reactor is divided and separated Half of the materials are stored as seeds;

[0039]The remaining half of the materials continue to react in t...

Embodiment 3

[0046](1) Prepare aluminum sulfate solution with aluminum ion concentration of 5.6g / L;

[0047](2) Add cobalt chloride solution and cobalt nitrate solution mixed solution with cobalt ion concentration of 195g / L, aluminum sulfate solution, and ammonium bicarbonate solution with concentration of 260g / L. These three solutions are added in parallel through metering pumps. In the reactor with deionized water as the bottom liquid, the feed rate of cobalt salt solution is 20ml / min, the feed rate of aluminum salt solution is 10ml / min, and the feed rate of ammonium bicarbonate solution is 40ml / min. Co-precipitation in the reactor The reaction conditions of the reaction system are as follows: pH value 7.2-7.4, temperature 30°C, reaction kettle speed 220 rpm, after 40 hours of reaction, the D50 particle size reaches 8 microns, at this time, the kettle is divided, and half of the separated materials are used as crystals. Kind of storage

[0048]The remaining half of the materials continue to react in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com