Die-cutting machine for avoiding printing film adhesion and using method thereof

A printing film and die-cutting machine technology, which is applied in metal processing and other directions, can solve the problems of inconvenient adjustment of the cutting knife distance, inconvenient cutting knife quick replacement, and affecting the cutting operation of film materials, so as to avoid adhesion and prevent sticking Attached, easy to adjust and replace the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

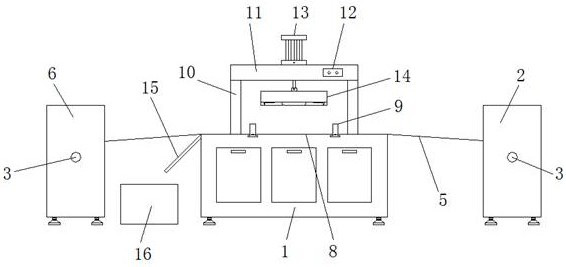

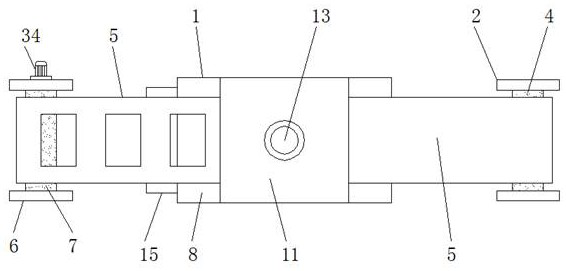

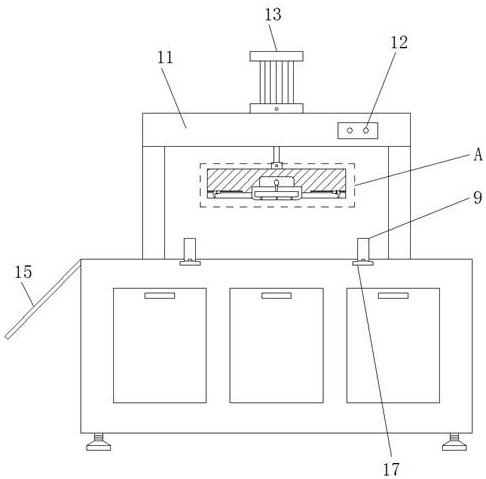

[0038] see Figure 1-9, the present invention provides a technical solution: a die-cutting machine that avoids printing film adhesion, including a die-cutting machine body 1, a feeding frame 2, a rotating shaft 3, a feeding roller 4, a printing film 5, a winding frame 6, Rewinding roller 7, die cutting table 8, limit roller 9, support frame 10, top plate 11, control box 12, cylinder 13, die cutting frame 14, material guide plate 15, material receiving box 16, adjustment chute 17, connection Sleeve 18, compression structure 19, installation chamber 20, air hole 21, compression cavity 22, catheter 23, expansion cavity 24, air bag 25, first limit groove 26, first knife rest 27, first die cutter 28, the first Two die cutters 29, mounting groove 30, second limit gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com