Preparation method of long-shelf-life glutinous rice sweet wine based on composite variable-pressure heating

A production method and shelf-life technology, applied in the field of sweet wine brewing, can solve the problems of short fresh-keeping shelf life, poor taste of sweet wine, long aging time, etc., and achieve the effects of extended shelf life, soft granules, and excellent taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

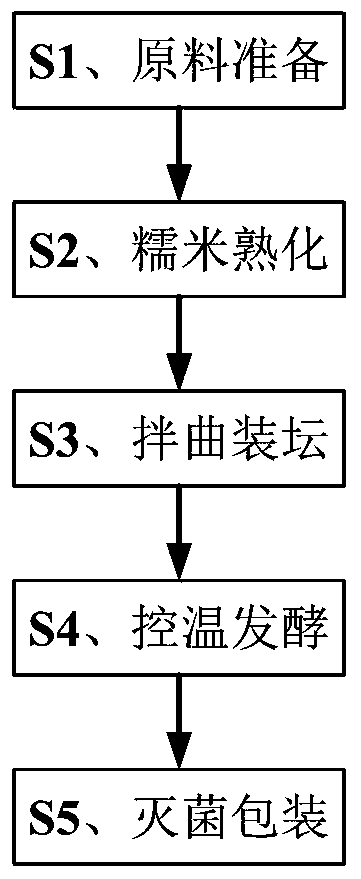

[0047] A method for making glutinous rice liqueur with long shelf life based on compound pressure swing heating, comprising the following steps:

[0048] S1. Raw material preparation: select sweet-scented osmanthus glutinous rice produced in Changle Town, Yueyang City, Hunan Province, screen out the glutinous rice with full grains, remove impurities, wash the rice with underground spring water from a well 10 to 15 meters underground, soak for 2 hours, and soften the glutinous rice by absorbing water;

[0049] S2. Glutinous rice ripening: The glutinous rice soaked in S1 is heated by steam and microwave compound pressure swing, which is divided into the following two steps:

[0050] a) Put the glutinous rice soaked in S1 into an airtight container, and feed micro-pressure steam into it, the steam pressure is 0.2Mpa, and the steam flow rate per 100kg of glutinous rice is 1500Nm 3 / h meter, the processing time is 3~5min;

[0051] b) The pressure steam that continues to be passed ...

Embodiment 2

[0056] A method for making glutinous rice liqueur with long shelf life based on compound pressure swing heating, comprising the following steps:

[0057] S1. Raw material preparation: select sweet-scented osmanthus glutinous rice produced in Changle Town, Yueyang City, Hunan Province, screen out glutinous rice with full grains, remove impurities, wash the rice with underground spring water from a well 10 to 15 meters underground, and soak for 3 hours to soften the glutinous rice by absorbing water;

[0058] S2. Glutinous rice ripening: The glutinous rice soaked in S1 is heated by steam and microwave compound pressure swing, which is divided into the following two steps:

[0059] a) Put the glutinous rice soaked in S1 into an airtight container, and introduce micro-pressure steam into it, the steam pressure is 0.4Mpa, and the steam flow rate per 100kg of glutinous rice is 2000Nm 3 / h meter, the processing time is 5min;

[0060] b) The pressure steam that continues to be passed...

Embodiment 3

[0065] A method for making glutinous rice liqueur with long shelf life based on compound pressure swing heating, comprising the following steps:

[0066] S1. Raw material preparation: select sweet-scented osmanthus glutinous rice produced in Changle Town, Yueyang City, Hunan Province, screen out glutinous rice with full grains, remove impurities, wash the rice with underground spring water from a deep well 10 to 15 meters underground, soak for 2.5 hours, and soften the glutinous rice by absorbing water;

[0067] S2. Glutinous rice ripening: The glutinous rice soaked in S1 is heated by steam and microwave compound pressure swing, which is divided into the following two steps:

[0068] a) Put the glutinous rice soaked in S1 into an airtight container, and introduce micro-pressure steam into it, the steam pressure is 0.3Mpa, and the steam flow rate per 100kg of glutinous rice is 1800Nm 3 / h meter, the processing time is 4min;

[0069] b) The pressure steam that continues to be p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com